Extraction method and purification method of acorus gramineus volatile oil

The technology of an extraction method and a purification method is applied in the field of extraction and purification of the volatile oil of Acorus calamus, can solve the problems of low extraction efficiency, high technical requirements, damage to the chemical substance structure of the volatile oil, etc., achieves mild extraction conditions, is suitable for popularization and application, and improves the The effect of extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] Embodiment 1 (preferred embodiment):

[0144] A method for extracting volatile oil of Acorus calamus, said extraction method comprising the following steps:

[0145] ①Pretreatment: take 20.000g of Shichangpu traditional Chinese medicine decoction pieces, dry, pulverize, and pass through a 30-mesh sieve to obtain Shichangpu powder;

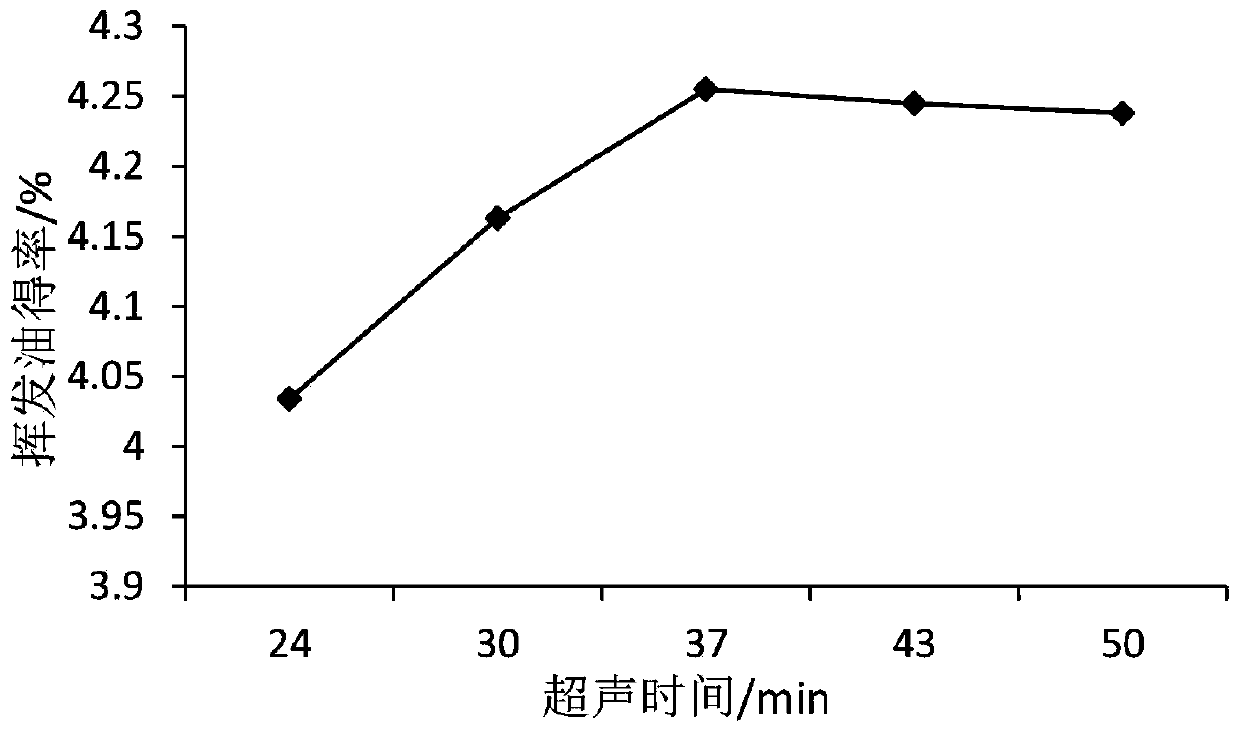

[0146] ②Ultrasonic extraction: Put the calamus powder in step ① into a round-bottomed flask, add petroleum ether at a material-liquid ratio of 1:12.5 (g / ml), then put the round-bottomed flask into an ultrasonic cleaning machine for ultrasonic extraction , the ultrasonic power is 182W, the ultrasonic extraction time is 37min, the ultrasonic extraction temperature is 30°C, and a reflux condenser is installed on the neck of the round bottom flask to condense and recover the extract;

[0147] ③Decompression suction filtration: Transfer the extract obtained in step ② into a Buchner funnel for circulating water vacuum decompression suction filtra...

Embodiment 2

[0155] A method for extracting volatile oil of Acorus calamus, said extraction method comprising the following steps:

[0156] ①Pretreatment: take 20.000g of Shichangpu traditional Chinese medicine decoction pieces, dry, pulverize, and pass through a 30-mesh sieve to obtain Shichangpu powder;

[0157] ②Ultrasonic extraction: Put the calamus powder in step ① into a round-bottomed flask, add petroleum ether at a material-liquid ratio of 1:24 (g / ml), then put the round-bottomed flask into an ultrasonic cleaning machine for ultrasonic extraction , the ultrasonic power is 100W, the ultrasonic extraction time is 50min, the ultrasonic extraction temperature is 50°C, and a reflux condenser is installed on the neck of the round bottom flask to condense and recover the extract;

[0158] ③Decompression suction filtration: Transfer the extract obtained in step ② into a Buchner funnel for circulating water vacuum decompression suction filtration. After the residue at the bottom of the roun...

Embodiment 3

[0166] A method for extracting volatile oil of Acorus calamus, said extraction method comprising the following steps:

[0167] ①Pretreatment: take 20.000g of Shichangpu traditional Chinese medicine decoction pieces, dry, pulverize, and pass through a 30-mesh sieve to obtain Shichangpu powder;

[0168] ②Ultrasonic extraction: Put the calamus powder in step ① into a round-bottomed flask, add petroleum ether at a material-to-liquid ratio of 1:8 (g / ml), then put the round-bottomed flask into an ultrasonic cleaning machine for ultrasonic extraction , the ultrasonic power is 250W, the ultrasonic extraction time is 24min, the ultrasonic extraction temperature is 25°C, and a reflux condenser is installed on the neck of the round bottom flask to condense and recover the extract;

[0169] ③Decompression suction filtration: Transfer the extract obtained in step ② into a Buchner funnel for circulating water vacuum decompression suction filtration. After the residue at the bottom of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com