Polymer composite microspheres, and preparation method and application thereof

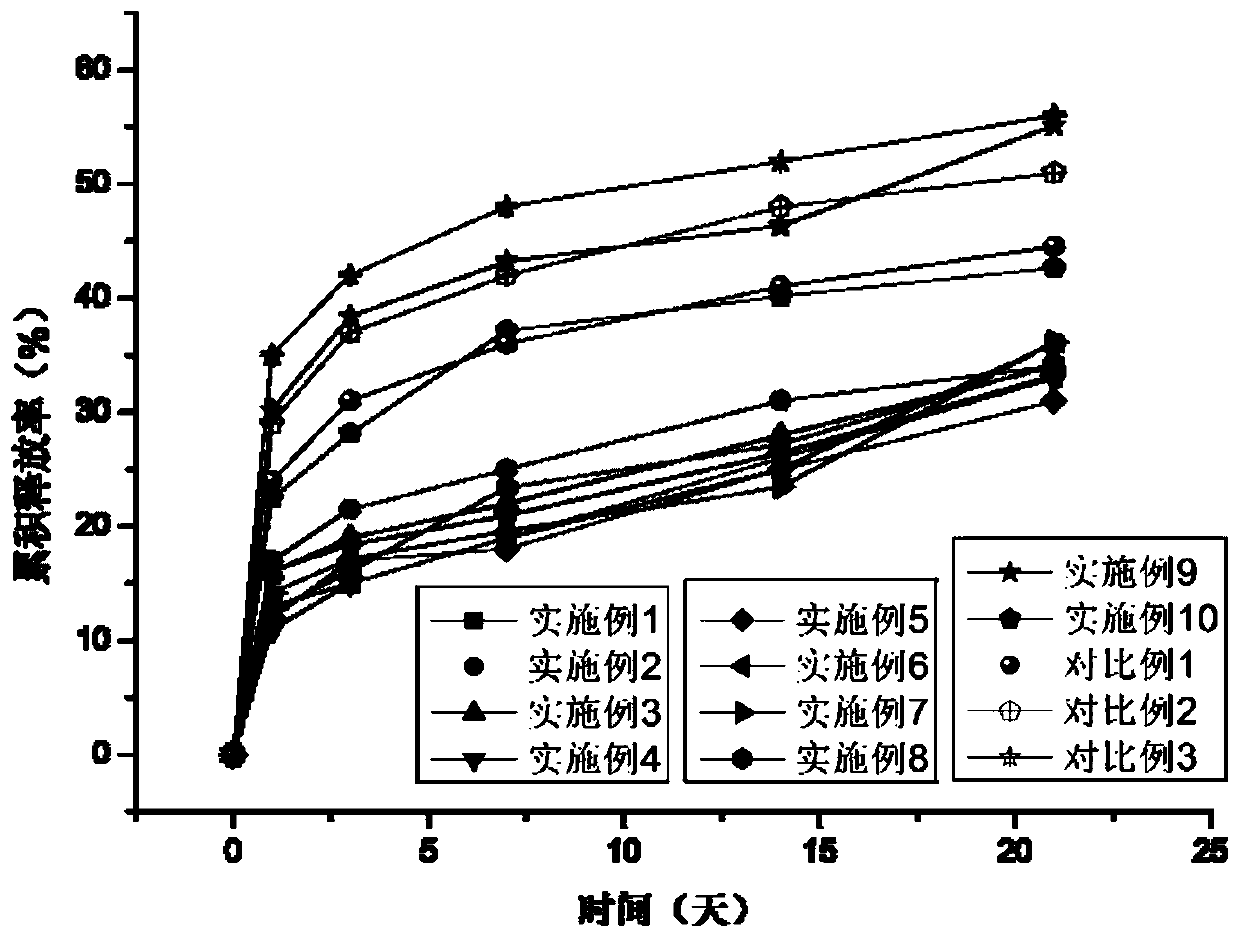

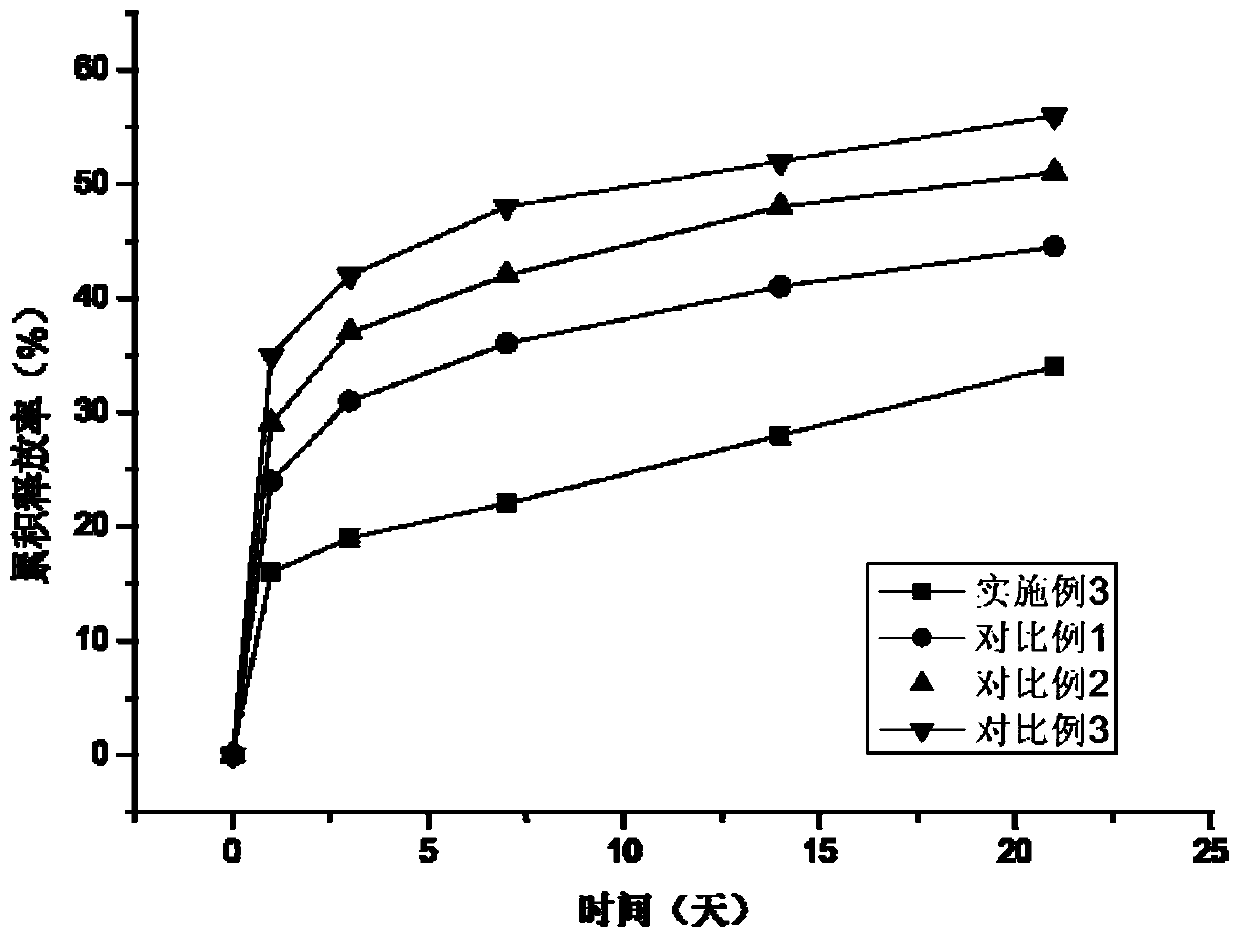

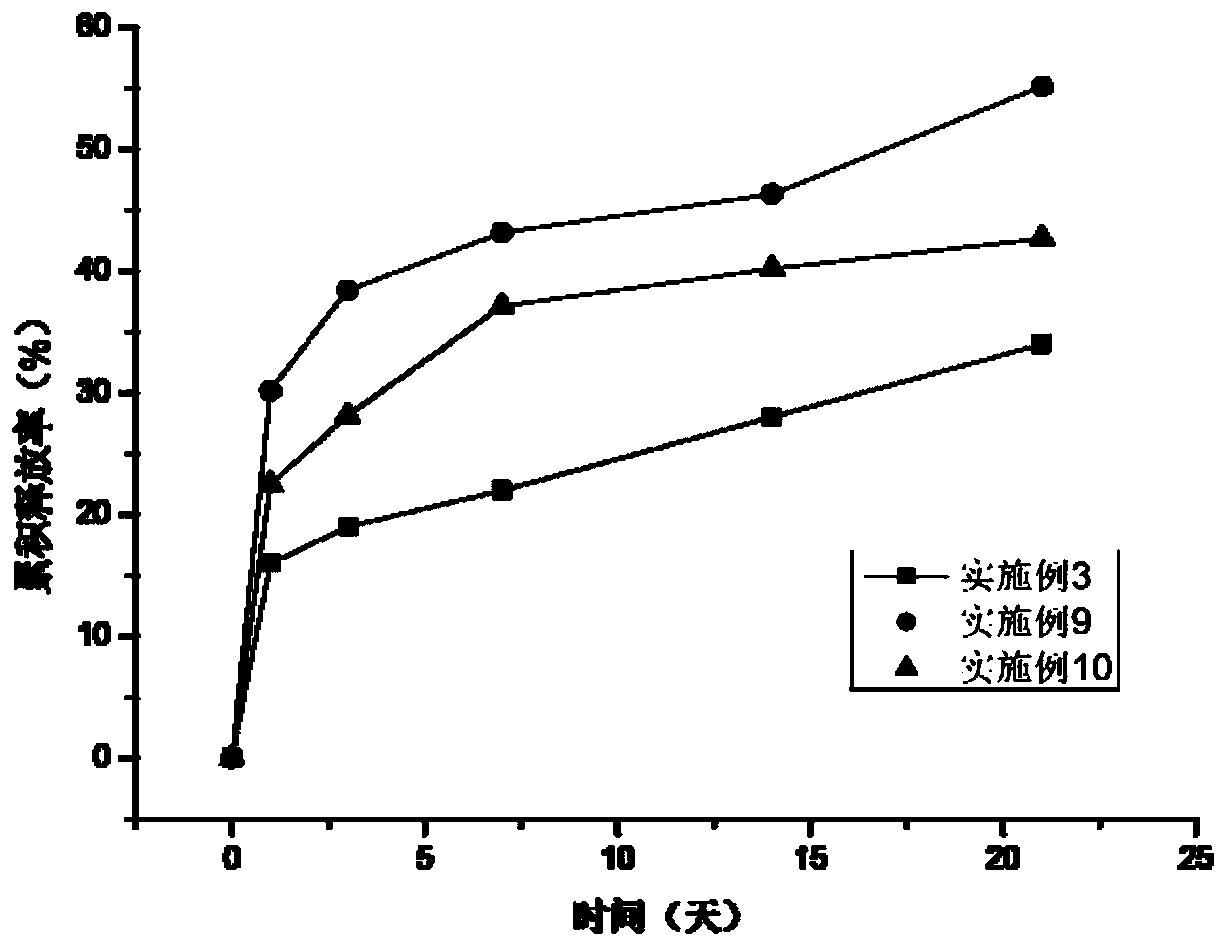

A technology of composite microspheres and polymers, applied in the directions of active ingredients of heterocyclic compounds, non-active ingredients of polymer compounds, microcapsules, etc. low release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The coating process can be general physical coating, and polymer compounds include water-soluble polymers and degradable polymers. Preferably, the preparation method of polymer composite microspheres comprises the following steps:

[0025] S1, preparation of pre-coating solution

[0026] Mix protein-binding functional molecules, albumin and water-soluble polymers to form a pre-coating solution, first use albumin and protein-binding functional molecules to combine, use the electrostatic force, hydrogen bond, affinity The combination of non-covalent bonds such as water force can make the sustained release performance of functional molecules prepared into microsphere materials better, and significantly reduce the burst release effect.

[0027] Specifically, the albumin is selected from any one or more of chicken serum albumin, bovine serum albumin, and human serum albumin. The specific functional molecules are combined to finally reduce the effect of burst release. The ...

Embodiment 1

[0048] The present embodiment provides a kind of preparation method of polymer composite microsphere, it comprises the following steps:

[0049] Dissolve 100mg warfarin sodium and 2000mg bovine serum albumin in 15mL aqueous solution containing 2000mg starch, and disperse for 30min at a speed of 500rpm to obtain a bovine serum albumin / starch aqueous solution loaded with warfarin sodium; take 1.0mL of the aqueous solution Pour into 10mL tetrahydrofuran solution containing 2.0g polybutylene succinate (molecular weight: 100,000 Daltons), and emulsify at 2000rpm for 2min; add the above emulsion into 500mL aqueous solution containing 1.0% methylcellulose , stirred at 550rpm at room temperature for 6h; washed 3 times, soaked in an aqueous solution containing potassium hydroxide, pH = 12 for 10min, washed 3 times again, centrifuged and freeze-dried at -50°C for 48h to obtain warfarin sodium release bovine serum albumin / polybutylene succinate composite microspheres.

Embodiment 2

[0051] The present embodiment provides a kind of preparation method of polymer composite microsphere, it comprises the following steps:

[0052] Dissolve 100 mg of dicoumarin and 1000 mg of human serum albumin in 15 mL of aqueous solution containing 3000 mg of cationic polyacrylamide, and disperse ultrasonically for 45 minutes to obtain a human serum albumin / cationic polyacrylamide aqueous solution loaded with dicoumarin; take 0.5 Pour this aqueous solution into 10 mL of tetrahydrofuran solution containing 1.5 g of polycaprolactone (molecular weight: 50,000 Daltons), and emulsify at 2000 rpm for 3 min; Stir at 350rpm for 8h; wash with water for 3 times, soak in an aqueous solution containing potassium hydroxide and pH=10 for 8min, wash with water again for 3 times, centrifuge and freeze-dry at -70°C for 36h to obtain the human dicoumarin release Serum albumin / polycaprolactone composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com