Negative material, negative plate, battery assembly and preparation methods

A technology for negative electrode materials and battery components, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of poor mechanical properties and collapse of MXene, and achieve the effect of improving electrical conductivity, good electrical conductivity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

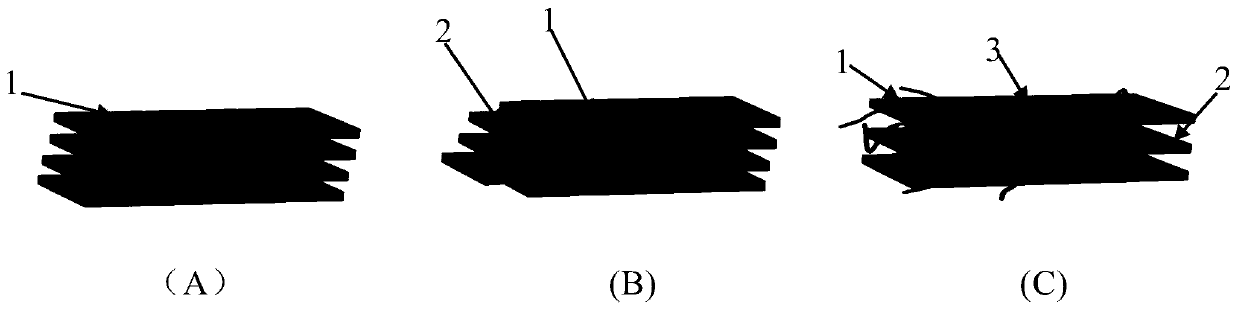

[0078] According to another aspect of the present invention, a kind of preparation method of negative electrode material is provided, comprising steps:

[0079] S1: After adding the graphene dispersion to the MXene dispersion at 0-30°C, perform ultrasonication in an inert atmosphere to obtain a suspension;

[0080] S2: removing the solvent in the suspension to obtain the negative electrode material.

[0081] According to the preparation method of the negative electrode material of the present invention, the negative electrode material of the present invention can be prepared, and the prepared negative electrode material can solve the problem of stacking and collapse of MXene, and can also solve the problem of poor mechanical properties and difficult film formation.

[0082] Wherein, the temperature in step S1 is typically but not limited to 0°C, 3°C, 5°C, 8°C, 10°C, 13°C, 15°C, 18°C, 20°C, 23°C, 25°C, 28°C and 30°C.

[0083] Because MXene is prone to oxidation when it is hig...

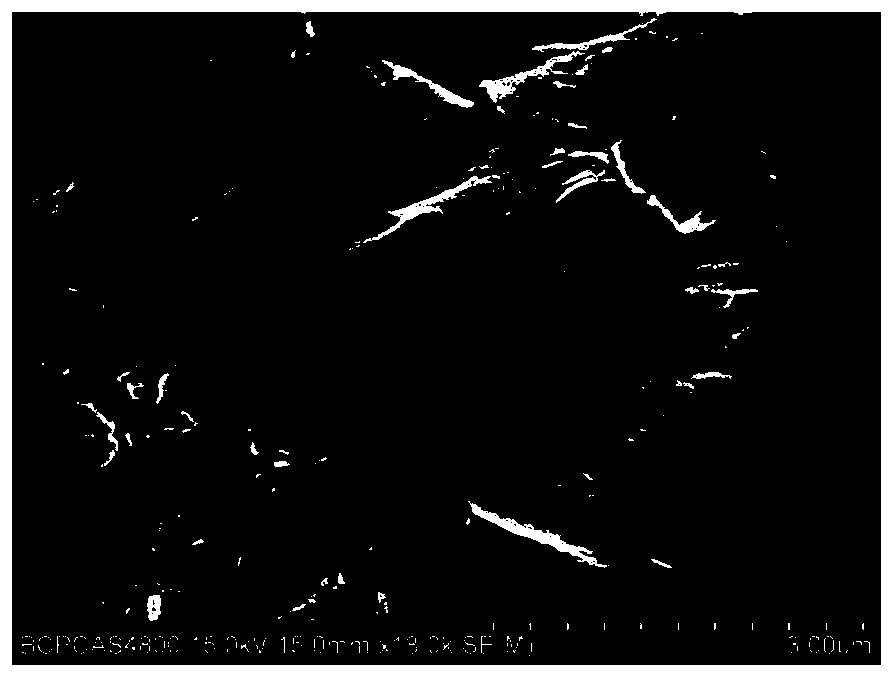

Embodiment 1

[0131] In this embodiment, step S1 is first carried out: after adding the graphene dispersion to the MXene dispersion at 0-30°C, ultrasonication is performed in an inert atmosphere to obtain a suspension; the specific operations are:

[0132] Take Ti 3 C 2 T x Dispersion (containing 100mg of Ti 3 C 2 T x) in a 500ml beaker, placed in an ice-water bath environment (control temperature below 10°C) while stirring, slowly add the prepared graphene dilute dispersion (containing 20mg graphene), stir for 15min, and dissolve the solution at 20KHZ Ultrasound was applied for 20 minutes while argon protection was introduced, and the temperature of the ultrasonic environment was controlled not to be higher than 25° C. to obtain a suspension.

[0133] Among them, Ti 3 C 2 T x The mass ratio to graphene is 1:0.2.

[0134] Then proceed to S2: remove the solvent in the suspension to obtain the negative electrode material.

[0135] Turn on the vacuum filtration device, filter the sus...

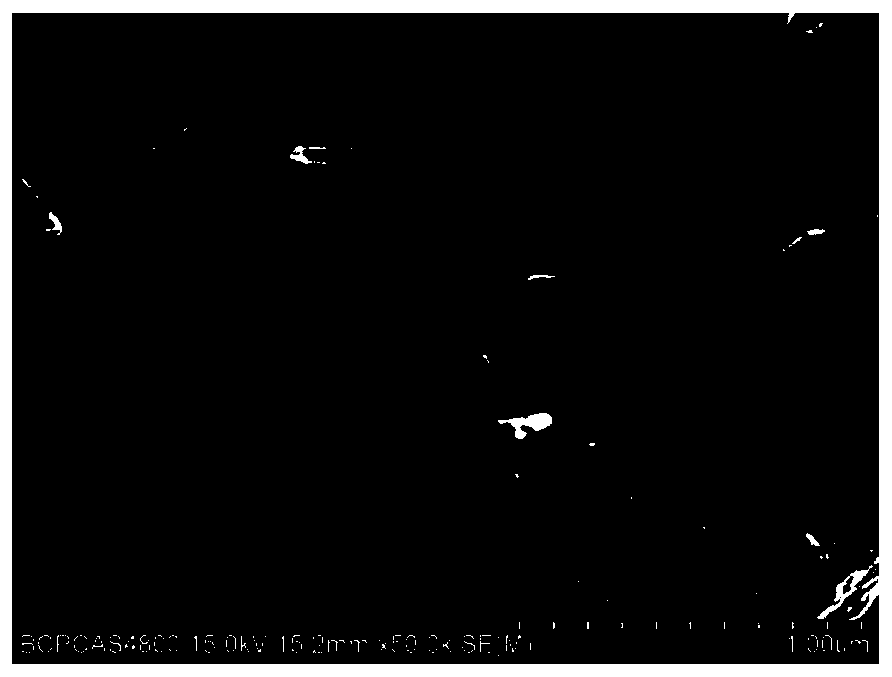

Embodiment 2

[0137] The other conditions of this embodiment and embodiment 1 are all the same, and the difference is that the carbon nanotube slurry is also added in the step S1, and the solid content of the carbon nanotube in the carbon nanotube slurry added is 5mg, namely The mass ratio of MXene to carbon nanotubes is 1:0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com