Method for testing thickness of oxide layer on surface of micro-nano aluminum ball

A technology of surface oxidation and testing methods, applied in measuring devices, material analysis using radiation diffraction, instruments, etc., can solve the problem of reducing the size of aluminum balls, and achieve accurate characterization and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

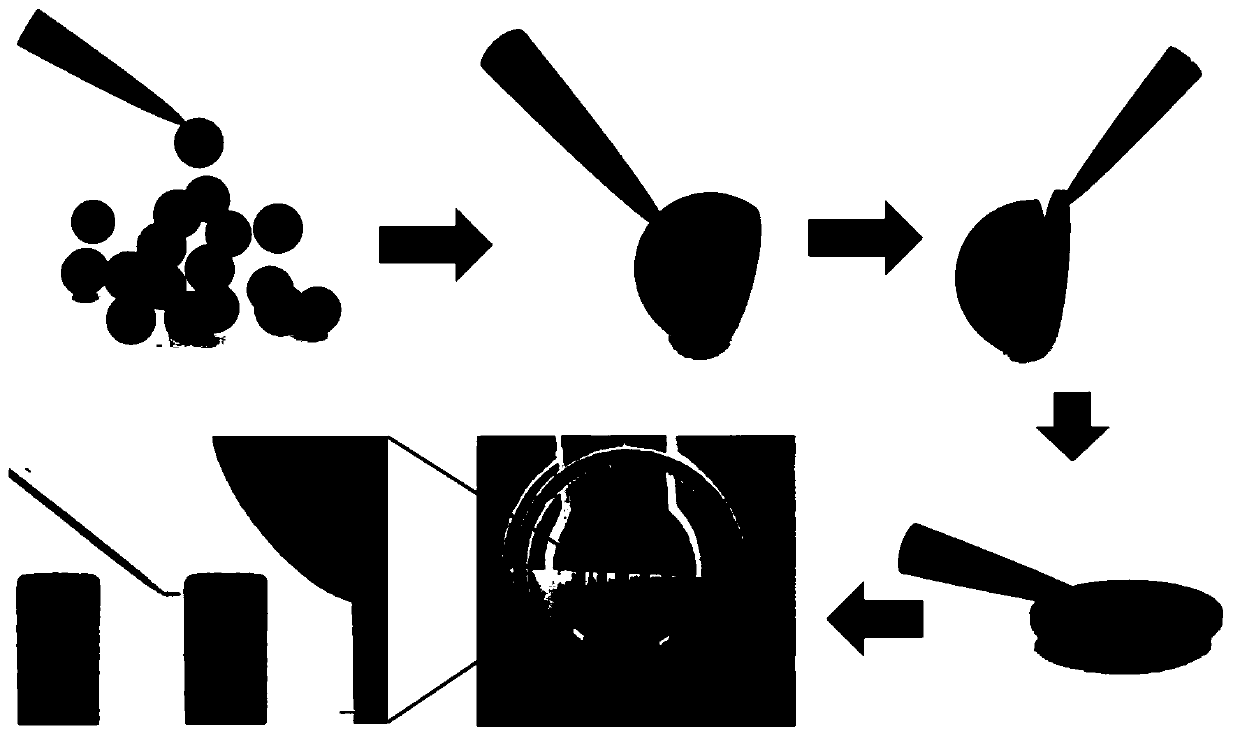

Method used

Image

Examples

Embodiment 1

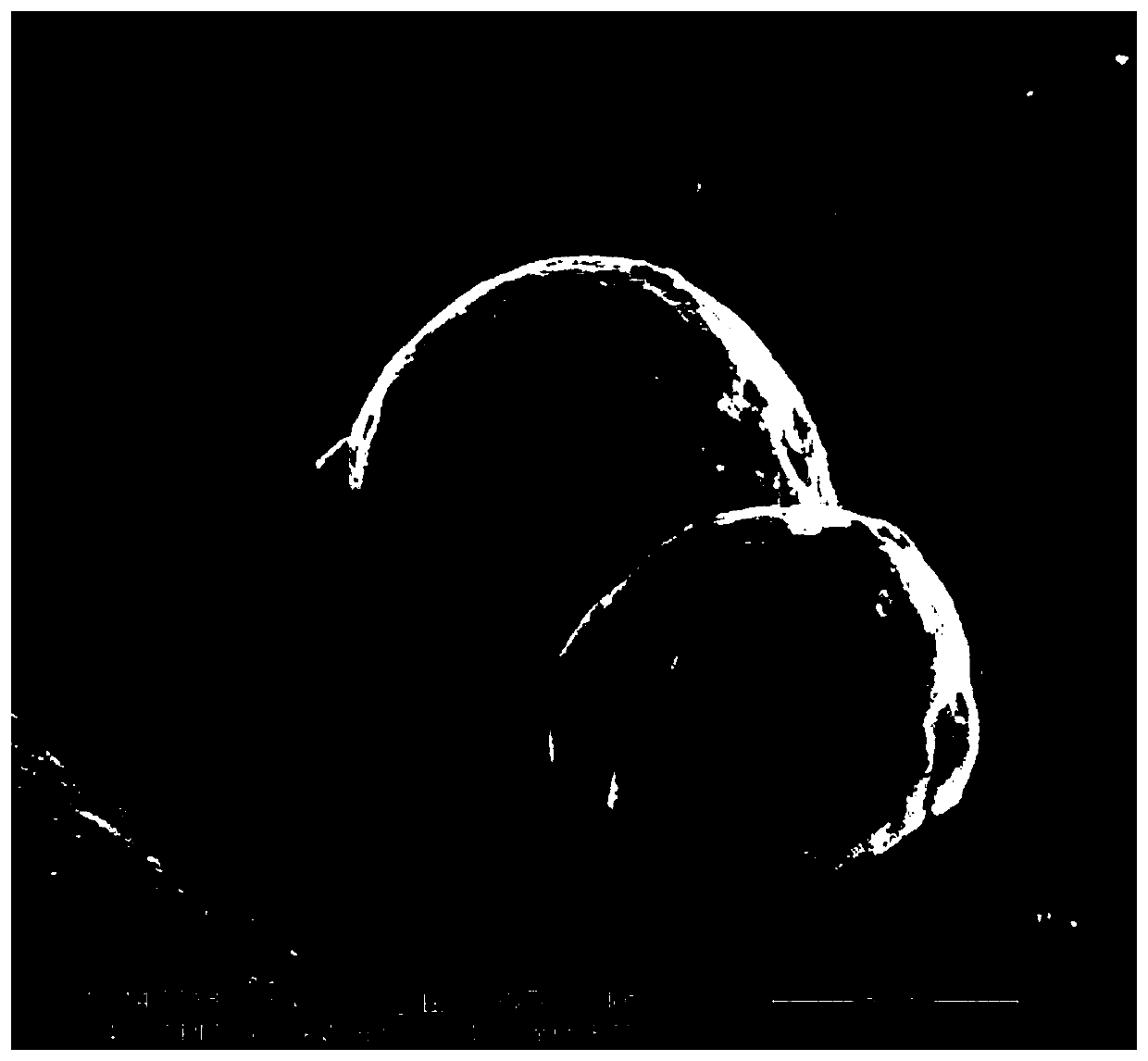

[0060] Such as figure 2 As shown, 2g of aluminum powder is dispersed on the surface of the conductive adhesive, put into the vacuum chamber of the focused ion beam system, and the air pressure is pumped to 10 -4 Pa; under the electronic imaging system of focused ion beam, choose such as image 3 Individual aluminum spheres around 10 μm in diameter are shown. Deposit a Pt protective layer on the surface of the aluminum ball to be processed through a gas injection system, and the current density of the ion beam during the deposition process is 4pA / μm 2 , with a deposition time of 2 minutes, we get Figure 4 The Pt protective layer with a thickness of about 1 μm on the surface of the aluminum ball shown; Figure 5 with Image 6 As shown, the Ga ion beam is used to cut the target area, the ion beam current is 3nA, and the aluminum ball matrix is removed along both sides of the Pt protective layer to obtain a thin slice sample with a thickness of 2 μm; Figure 7 shown by 2p...

Embodiment 2

[0062] Disperse 3g of aluminum powder on the surface of the conductive adhesive, put it into the vacuum chamber of the focused ion beam system, and pump the air pressure to 10 - 4 Pa; a single aluminum sphere with a diameter of around 5 μm was selected under an electron imaging system with a focused ion beam. Deposit a Pt protective layer on the surface of the aluminum ball to be processed through a gas injection system, and the current density of the ion beam during the deposition process is 2pA / μm 2 , the deposition time was 1min, and a Pt protective layer with a thickness of about 1.3 μm on the surface of the aluminum ball was obtained; the Ga ion beam was used to cut the target area, the ion beam current was 2nA, and the aluminum ball matrix was removed along both sides of the Pt protective layer, and the thickness was obtained 2μm flake samples; pass 2pA / μm 2 The Pt ion beam deposition connects the nano-manipulator probe to the sheet by welding, and the sheet can be mov...

Embodiment 3

[0064] Disperse 5g of aluminum powder on the surface of the conductive adhesive, put it into the vacuum chamber of the focused ion beam system, and pump the air pressure to 10 - 4 Pa; a single aluminum sphere with a diameter of around 3 μm was selected under an electron imaging system with a focused ion beam. Deposit a Pt protective layer on the surface of the aluminum ball to be processed through a gas injection system, and the current density of the ion beam during the deposition process is 2pA / μm 2 , the deposition time was 1min, and a Pt protective layer with a thickness of about 1.5 μm on the surface of the aluminum ball was obtained; the Ga ion beam was used to cut the target area, and the ion beam current was 3nA, and the aluminum ball matrix was removed along both sides of the Pt protective layer, and the thickness was obtained. 1μm flake sample; pass 2pA / μm 2 The Pt ion beam deposition connects the nano-manipulator probe to the sheet by welding, and the sheet can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com