Preparation method of nanometer magnesium silicate hydroxide, and preparation method and application of anti-wear agent

A technology of magnesium hydroxysilicate and magnesium silicate, applied in the directions of magnesium silicate, silicate, additives, etc., can solve the problems such as synthesis and surface modification of sheet-like nano-magnesium hydroxysilicate that are not mentioned, and achieve a preparation method. Simple and feasible, strong operability, controllable synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

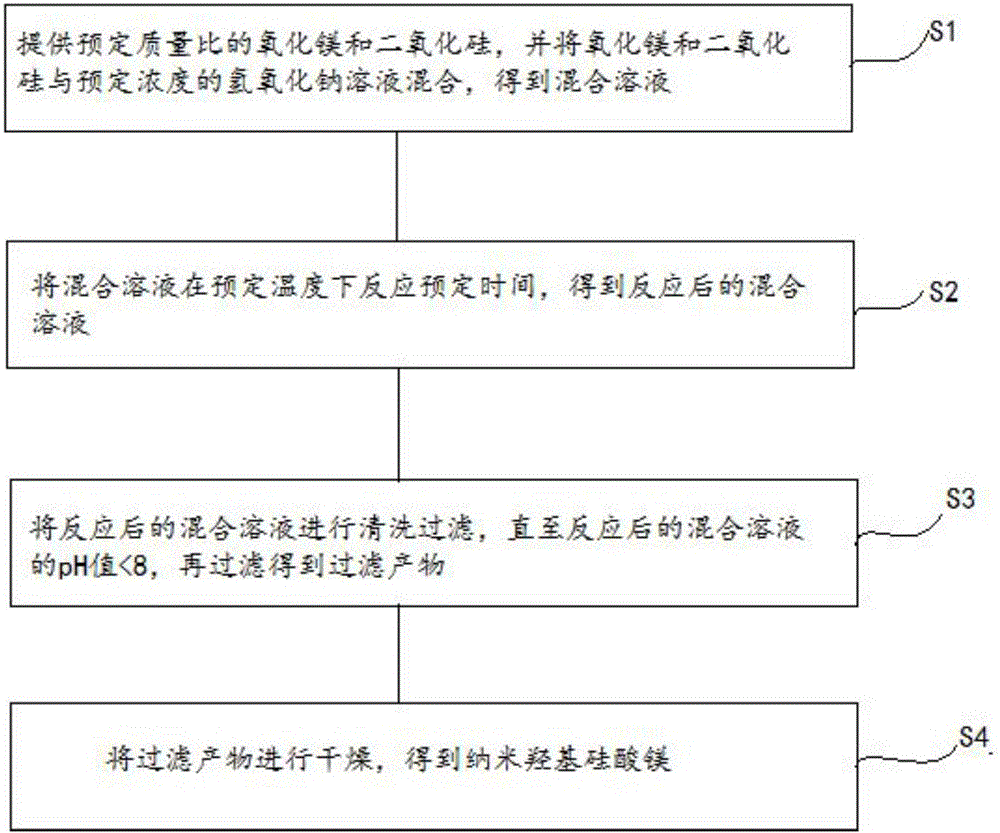

[0033] Such as figure 1 As shown, the preparation method of the nano-hydroxymagnesium silicate according to the embodiment of the present invention comprises the following steps:

[0034] S1. Providing magnesium oxide and silicon dioxide in a predetermined mass ratio, and mixing the magnesium oxide and silicon dioxide with a sodium hydroxide solution of a predetermined concentration to obtain a mixed solution.

[0035] S2. Reacting the mixed solution at a predetermined temperature for a predetermined time to obtain a reacted mixed solution.

[0036] S3. Wash and filter the reacted mixed solution until the pH value of the reacted mixed solution is <8, and then filter to obtain a filtered product.

[0037] S4. Drying the filtered product to obtain the nano-hydroxymagnesium silicate.

[0038] Therefore, according to the preparation method of nano-hydroxy magnesium silicate according to the embodiment of the present invention, magnesium oxide and silicon dioxide are used as raw ...

Embodiment 1

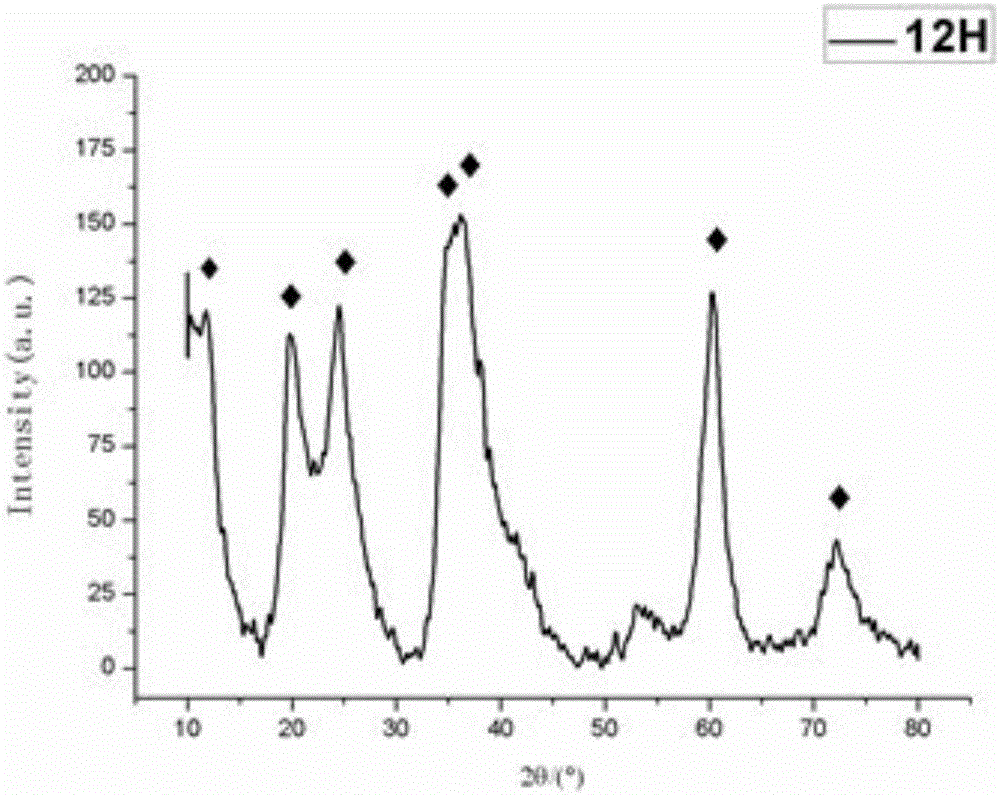

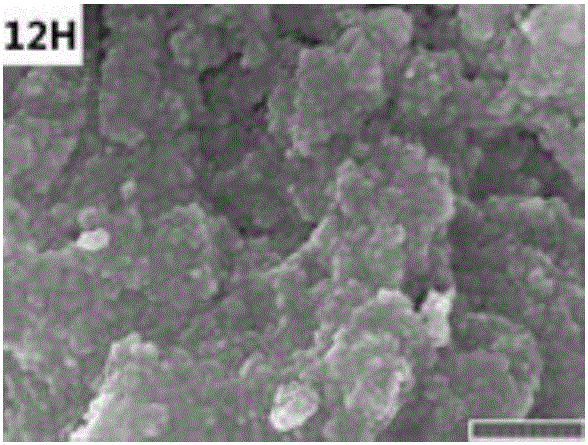

[0060] Put 2.143g of magnesia and 2.143g of silicon dioxide into the container and mix thoroughly, add 200ml of deionized water and stir to dissolve with a magnetic heating stirrer, then add 5mol / L of sodium hydroxide titration solution and stir for 5 minutes, put put into the reaction kettle to heat, the heating temperature is set to 200°C, the reaction time is set to 12 hours, and the reaction product is obtained after cooling treatment; the reaction product is washed and filtered with deionized water until the pH value of the solution is less than 8, and the filtered The composition is placed in a drying device, the set temperature is 70°C, and after drying, a sheet-like nano-powder of magnesium hydroxysilicate is obtained, such as figure 2 with image 3 shown.

[0061] Depend on image 3 It can be seen that the embodiment of the present invention obtains lamellar nanoparticles, thereby realizing the controllable synthesis of hydroxymagnesium silicate nanoparticles.

Embodiment 2

[0063] Put 2.143g of magnesia and 2.143g of silicon dioxide into the container and mix thoroughly, add 200ml of deionized water and stir to dissolve with a magnetic heating stirrer, then add 6mol / L of sodium hydroxide titration solution and stir for 5 minutes, put put into the reaction kettle to heat, the heating temperature is set to 220°C, the reaction time is set to 72 hours, and the reaction product is obtained after cooling treatment; the reaction product is washed and filtered with deionized water until the pH value of the solution is less than 8, and the filtered The composition is placed in a drying device, the set temperature is 80°C, and after drying, the nano-powder of sheet-like magnesium hydroxysilicate is obtained, such as Figure 4 with Figure 5 shown.

[0064] Depend on Figure 5 It can be seen that tubular nanoparticles are obtained in the embodiment of the present invention, thereby realizing the controllable synthesis of hydroxymagnesium silicate nanopart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com