Comprehensive process for recovering and treating indigo blue powder waste slag

A technology for recovery and treatment of slag, which is applied to the removal of alkali metal compounds, solid waste, alkali metal oxides/hydroxides, etc., to achieve the effects of reasonable process design, high yield, and simple and feasible production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

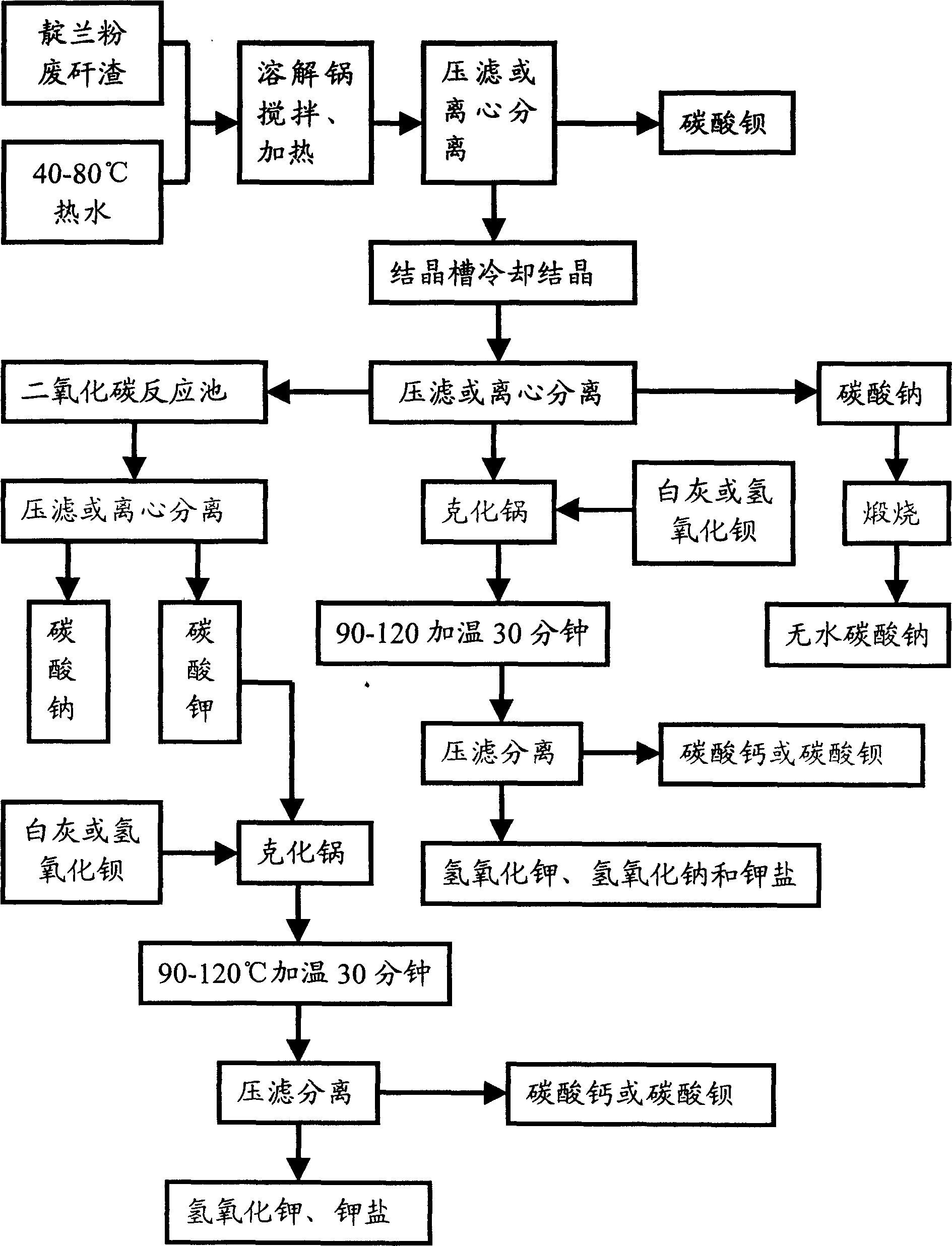

Image

Examples

Embodiment 1

[0036] Example 1 (high metering)

[0037] Add 600kg of waste slag and 700kg of water at 60-80°C to the melting pot with a specific gravity of 1.38, keep it warm for 10-30 minutes, stir well, heat to 40-80°C, and wait for the waste slag to 40-80°C. Fully dissolved, and centrifuged to remove slag to generate mother liquor.

[0038] Pour the mother liquor into the crystallization tank for cooling and crystallization, and keep the temperature at 8-12°C for 30-48 hours for cooling and crystallization.

[0039] The cooling and crystallizing mother liquor is separated into crystals by means of pressure filtration or centrifugation, and the separated crystals are sodium carbonate with crystal water, and the crystals are calcined to produce anhydrous sodium carbonate.

[0040] The mother liquor from which the mixed crystals are separated is liquid A, pour liquid A into a lime pot, heat to 90-120°C, add 120kg of lime, stir well, keep the temperature at 100°C, heat for 30-60 minutes, th...

Embodiment 2

[0041] Example 2 (low metering)

[0042]Add 400kg of waste slag and 450kg of water at 60-80°C to the melting pot with a specific gravity of 1.31, keep warm for 10-30 minutes, stir well, heat to 40-80°C, and wait for the waste slag to 40-80°C. Fully dissolved, and centrifuged to remove slag to generate mother liquor.

[0043] Pour the mother liquor into the crystallization tank for cooling and crystallization, and keep the temperature at 8-12°C for 30-48 hours for cooling and crystallization.

[0044] The cooled and crystallized mother liquor is separated into crystals by means of pressure filtration or centrifugation, the separated crystals are sodium carbonate with crystal water, and the crystals are calcined to produce anhydrous sodium carbonate.

[0045] The mother liquor from which crystals are separated is liquid A, pour liquid A into a lime pot, heat to 90-120°C, add 90kg of lime, stir well, keep the temperature at 100°C, heat for 30-60 minutes, cool down to 70°C and pr...

Embodiment 3

[0046] Example 3 (medium metering)

[0047] Add 500kf of waste slag and 575kg of water at 60-80°C to the melting pot with a specific gravity of 1.345, keep warm for 10-30 minutes, stir well, heat to 40-80°C, and wait for the waste slag Fully dissolved, and centrifuged to remove slag to generate mother liquor.

[0048] Pour the mother liquor into the crystallization tank for cooling and crystallization, and keep the temperature at 8-12°C for 30-48 hours for cooling and crystallization.

[0049] The cooled and crystallized mother liquor is separated into crystals by means of pressure filtration or centrifugation, the separated crystals are sodium carbonate with crystal water, and the crystals are calcined to produce anhydrous sodium carbonate.

[0050] The mother liquor from which the mixed crystals are separated is liquid A, pour liquid A into a lime pot, heat to 90-120°C, add 105kg of lime, stir well, keep the temperature at 100°C, heat for 30-60 minutes, then cool down to 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com