Drum and multilayer type woven fabric drying oven for stentering and setting machine

A stenter setting machine, multi-layer technology, applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve the problems of increasing the space occupied by the oven, inconvenient operation, and large oven volume, etc., to achieve reduction Small space occupation volume, efficient heat treatment effect, and the effect of avoiding noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

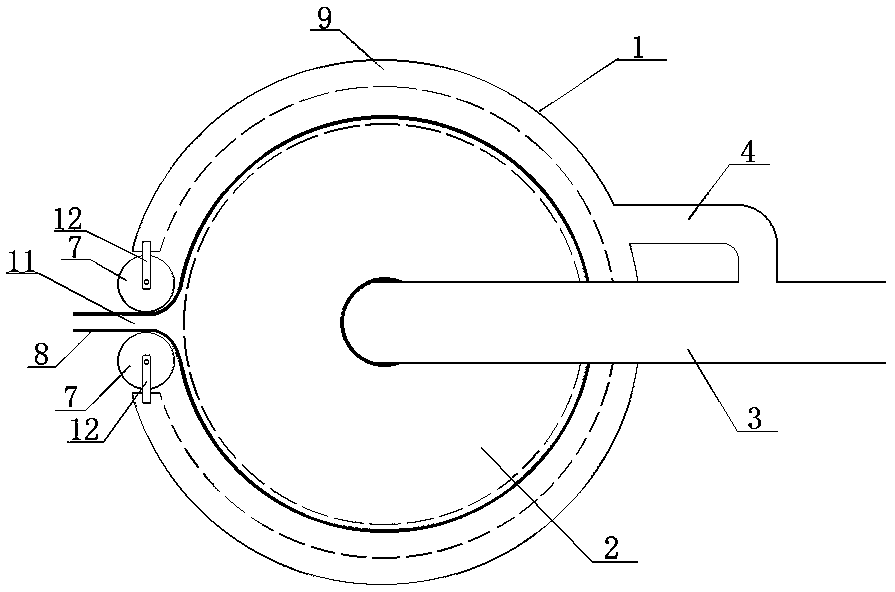

[0018] The present invention has designed a kind of cylinder multi-layer type weaving oven device for tenter setting machine, as figure 1 and figure 2 As shown, it specifically includes an outer barrel body 1 , an inner barrel body 2 , a heat conduction main pipe 3 , a heat conduction auxiliary pipe 4 , a rotating motor 5 , a relay pipe 6 and two guide rollers 7 .

[0019] Wherein, the length of the inner barrel body 2 is adapted to the width of the weaving cloth 8, the length of the outer barrel body 1 is greater than the length of the inner barrel body 2, and both ends of the outer barrel body 1 and the inner barrel body 2 are closed; The side of the barrel body 1 is provided with a slot 11 running through its inner and outer space along the direction of the distance between its two ends, the slot 11 connects the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com