Anti-pollution and anti-blocking asphalt conveying pipe

A technology for conveying pipes and asphalt, which is applied in the direction of pipes, rigid pipes, and pipeline protection. It can solve the problems of asphalt agglomeration, blockage of pipes, and obstruction of asphalt transmission, and achieve the effects of improving fluidity, avoiding blockage, and efficient heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

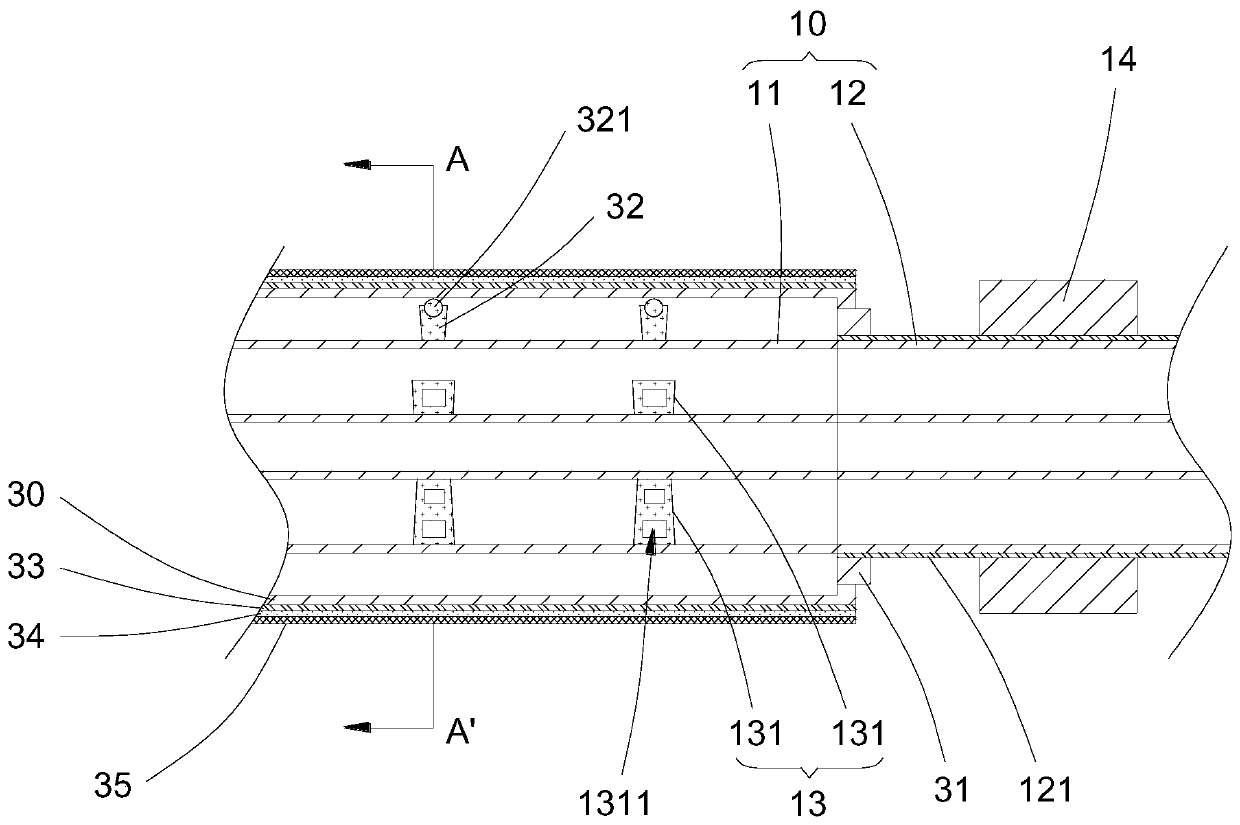

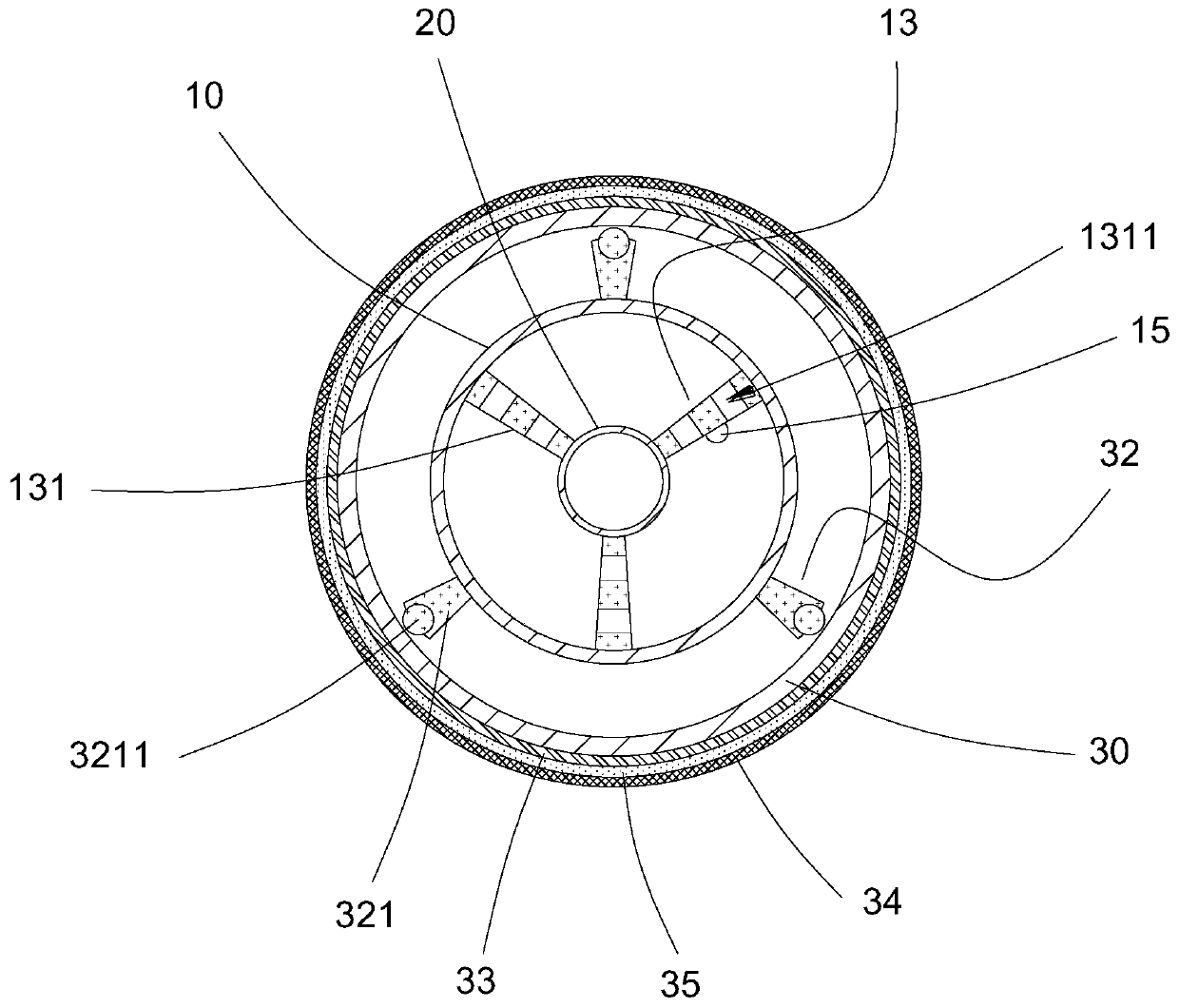

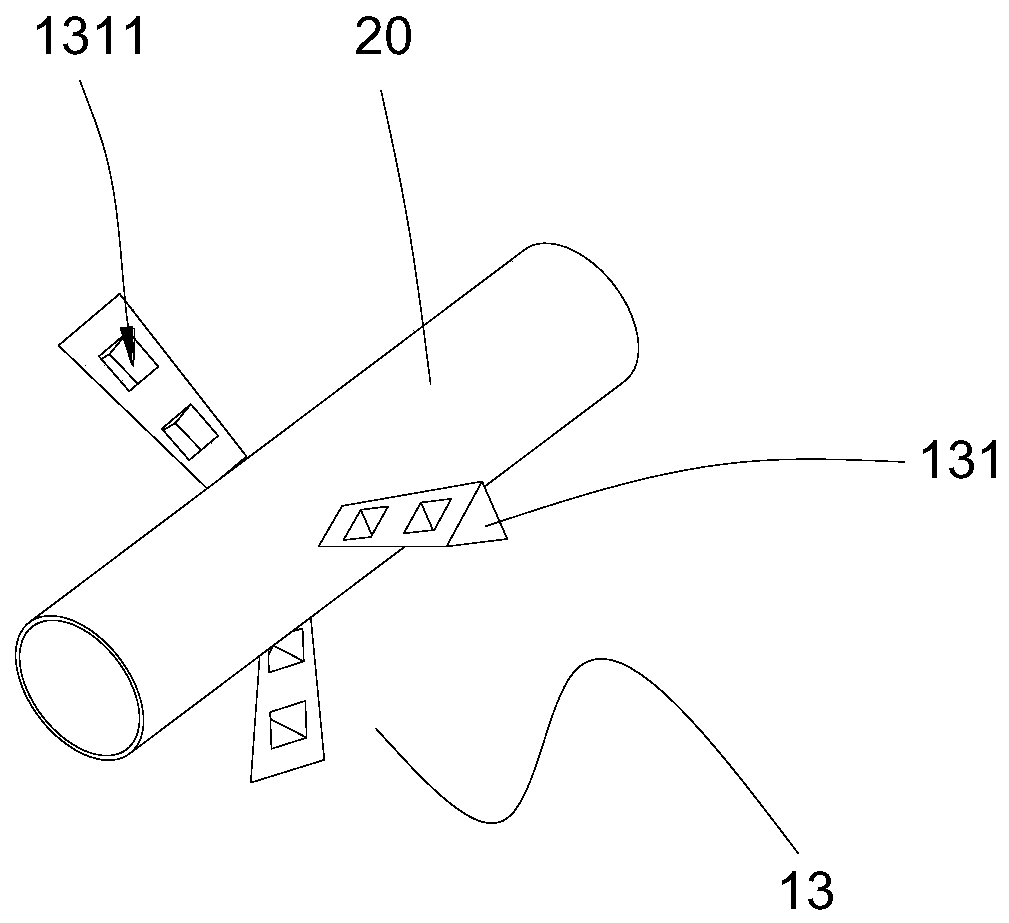

[0022] refer to Figure 1 to Figure 3 .

[0023] The embodiment of the present invention discloses an anti-fouling and anti-blocking asphalt delivery pipe, which includes a delivery pipe body 10, and an inner heat-conducting oil pipe 20 is arranged inside the delivery pipe body 10, and the space between the delivery pipe body 10 and the inner heat-conducting oil pipe 20 is formed In the material delivery chamber for circulating asphalt, the inner heat transfer oil pipe 20 forms an inner heat transfer oil chamber for circulating heat transfer oil. The delivery pipe body 10 includes a first material pipe 11 and a second material pipe 12 connected to each other. The first material pipe 11 It is integrall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com