A coolant temperature control system, engine assembly and vehicle

A coolant temperature and control system technology, applied in coolant flow control, engine components, engine cooling, etc., can solve problems such as poor reliability, affecting engine operation, low ambient temperature, etc., to improve reliability and service life , The effect of reducing vehicle maintenance costs and safe heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

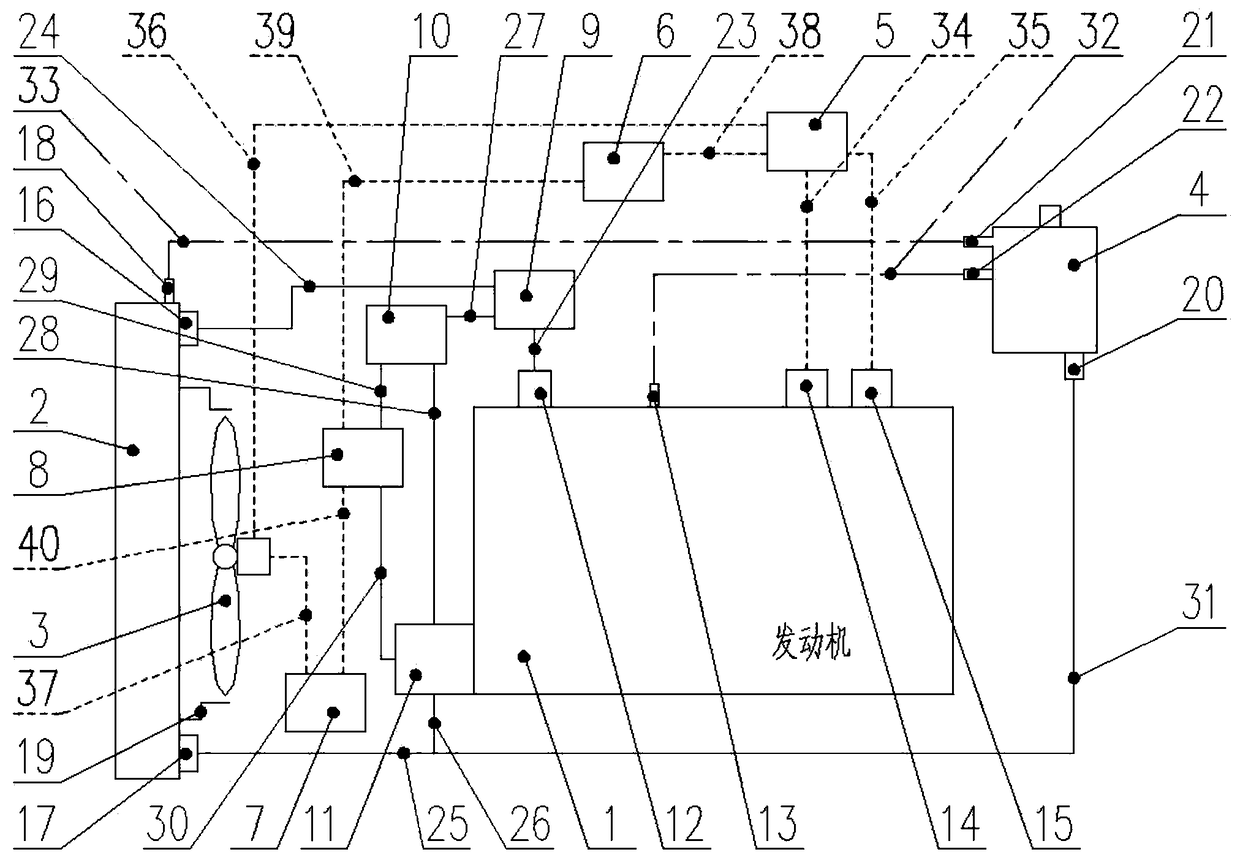

[0030] In the drawings, the same or similar reference numerals are used to denote the same or similar elements or elements having the same or similar functions. The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

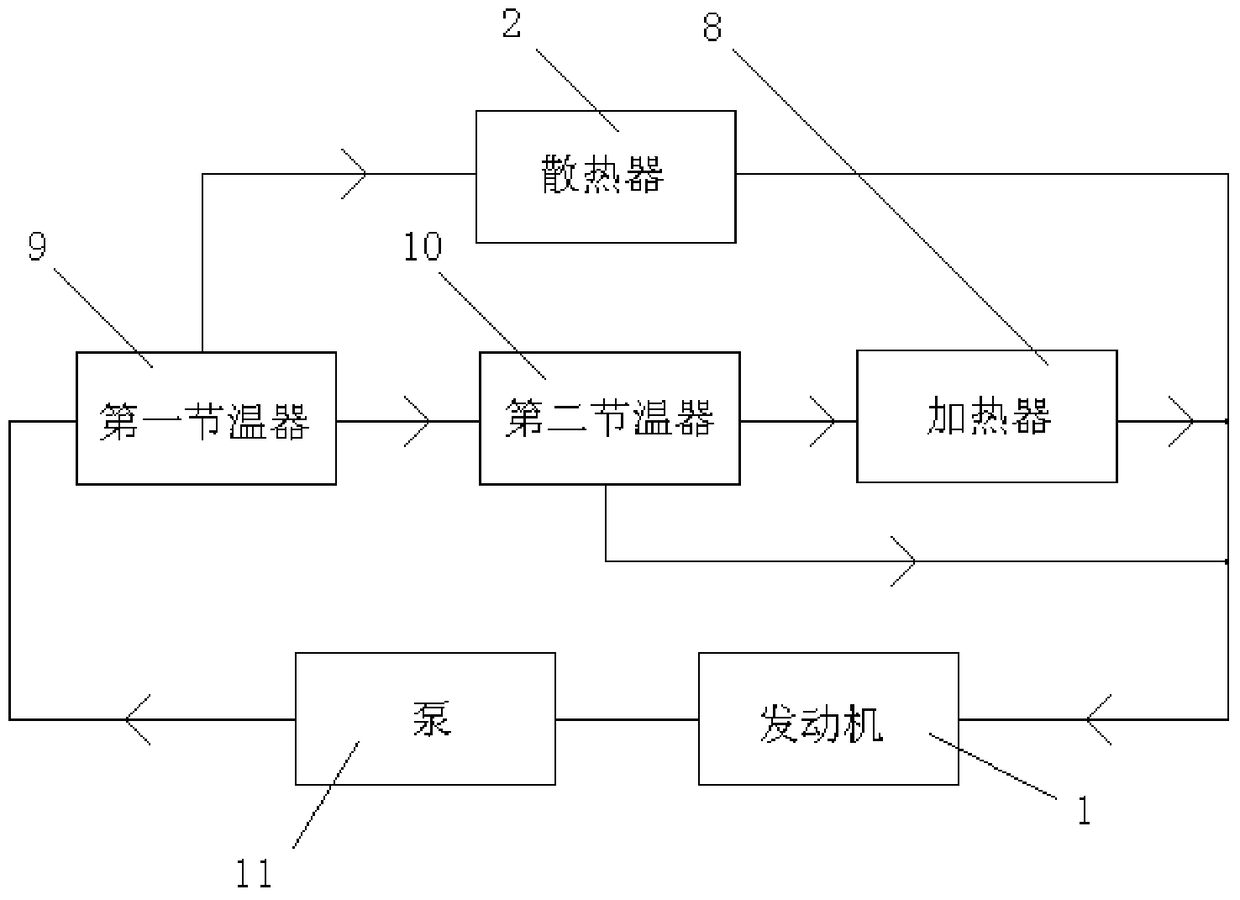

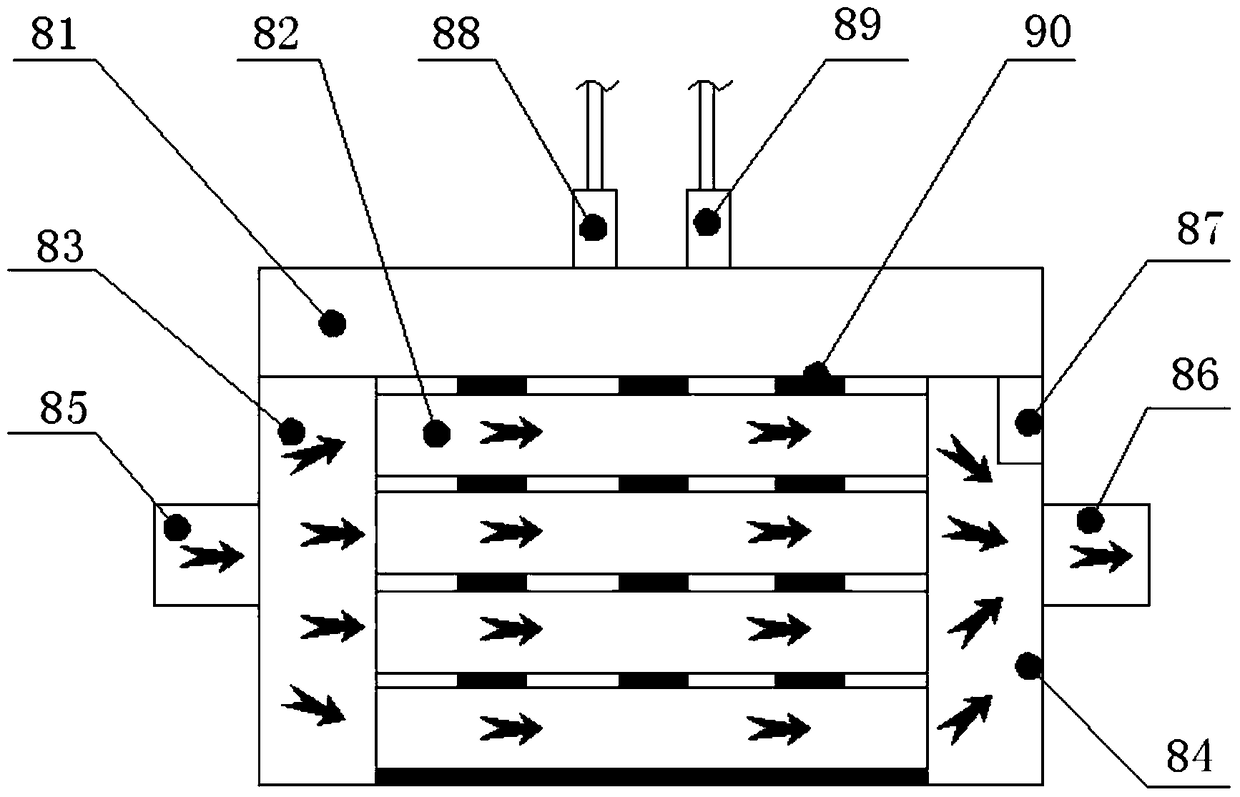

[0031] The coolant temperature control system of the present invention includes a radiator and a heater. When the temperature of the engine coolant is higher than the first threshold temperature (high temperature T2), the engine coolant is made to circulate through the radiator, and when the temperature of the engine coolant is lower than the second threshold temperature (cold temperature T1), Engine coolant is caused to circulate through the heater, wherein the first threshold temperature is higher than the second threshold temperature, and the heater is a magnetic induction heater.

[0032] By using the magnetic induction coolant heater to heat the coolant under low temperature conditions, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com