Waterborne polyurethane as well as preparation method and application thereof

A water-based polyurethane and amino technology, used in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of air pollution, neutralizer toxicity, human harm, etc., and achieve excellent flexibility, biological Good compatibility and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

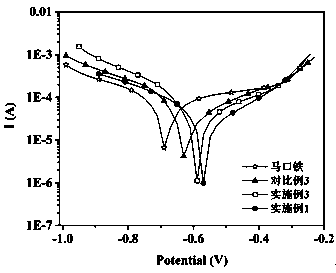

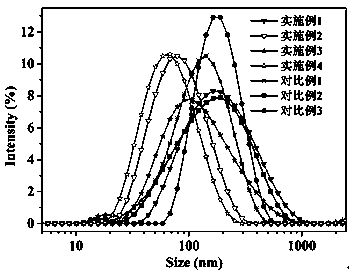

Embodiment 1

[0038] Take 300 parts of castor oil (hydroxyl value 164 mg KOH / g) and 195 parts of IPDI, stir in an oil bath at 50 °C at 100 r / min for 10 min, add 0.35 parts of DBTDL, continue stirring and reacting in an oil bath at 50 °C for 1 h, add 50 1 part of MDEA continued to react. When the viscosity of the solution increased to the point where it could hardly flow, add 800 parts of MEK, and continue to stir and react at 50°C for 1 hour. The reaction system became clear and transparent. Stop heating. After reaching 300 r / min, add 2500 parts of 30 ℃ aqueous solution in which 38 parts of glutamic acid was dissolved, continue to stir for 5 min under ice bath, remove the ice bath, and continue to stir for 1 h; the product is rotary evaporated to obtain a cationic water-based polyurethane emulsion.

Embodiment 2

[0040] Take 300 parts of modified castor oil (hydroxyl value 208 mg KOH / g) and 250 parts of IPDI, stir in an oil bath at 50 °C at 100 r / min for 10 min, add 0.35 parts of DBTDL, and continue stirring and reacting in an oil bath at 50 °C for 1 h , add 65 parts of MDEA to continue the reaction, when the viscosity of the solution increases to almost flow, add 1000 parts of MEK, continue to stir and react at 50 ℃ for 1h, the reaction system becomes clear and transparent, stop heating, wait for the solution to cool to room temperature , after the rotation speed was adjusted to 300 r / min, add 3000 parts of 30 ℃ aqueous solution in which 48 parts of glutamic acid was dissolved, continue to stir for 5 min under ice bath, remove the ice bath, and continue to stir for 1 h; the product was rotary evaporated to obtain cationic water-based polyurethane emulsion.

Embodiment 3

[0042] Take 300 parts of castor oil (hydroxyl value 164 mg KOH / g) and 195 parts of IPDI, stir in an oil bath at 50 °C at 100 r / min for 10 min, add 0.35 parts of DBTDL, continue stirring and reacting in an oil bath at 50 °C for 1 h, add 50 1 part of MDEA continued to react. When the viscosity of the solution increased to the point where it could hardly flow, add 800 parts of MEK, and continue to stir and react at 50°C for 1 hour. The reaction system became clear and transparent. Stop heating. After reaching 300 r / min, add 2500 parts of 30 ℃ aqueous solution dissolved with 38 parts of aspartic acid, continue to stir for 5 min under ice bath, remove the ice bath, and continue to stir for 1 h; the product is rotary evaporated to obtain cationic water-based polyurethane emulsion .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com