Potassium magnesium phosphate cement-based inorganic rapid repair material for ballasted tracks

A potassium magnesium phosphate cement, ballastless track technology, applied in the field of building materials, can solve the problems of poor high temperature resistance, poor acid and alkali resistance, high brittleness, etc., and achieve the effects of strong wear resistance, fast setting and hardening, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

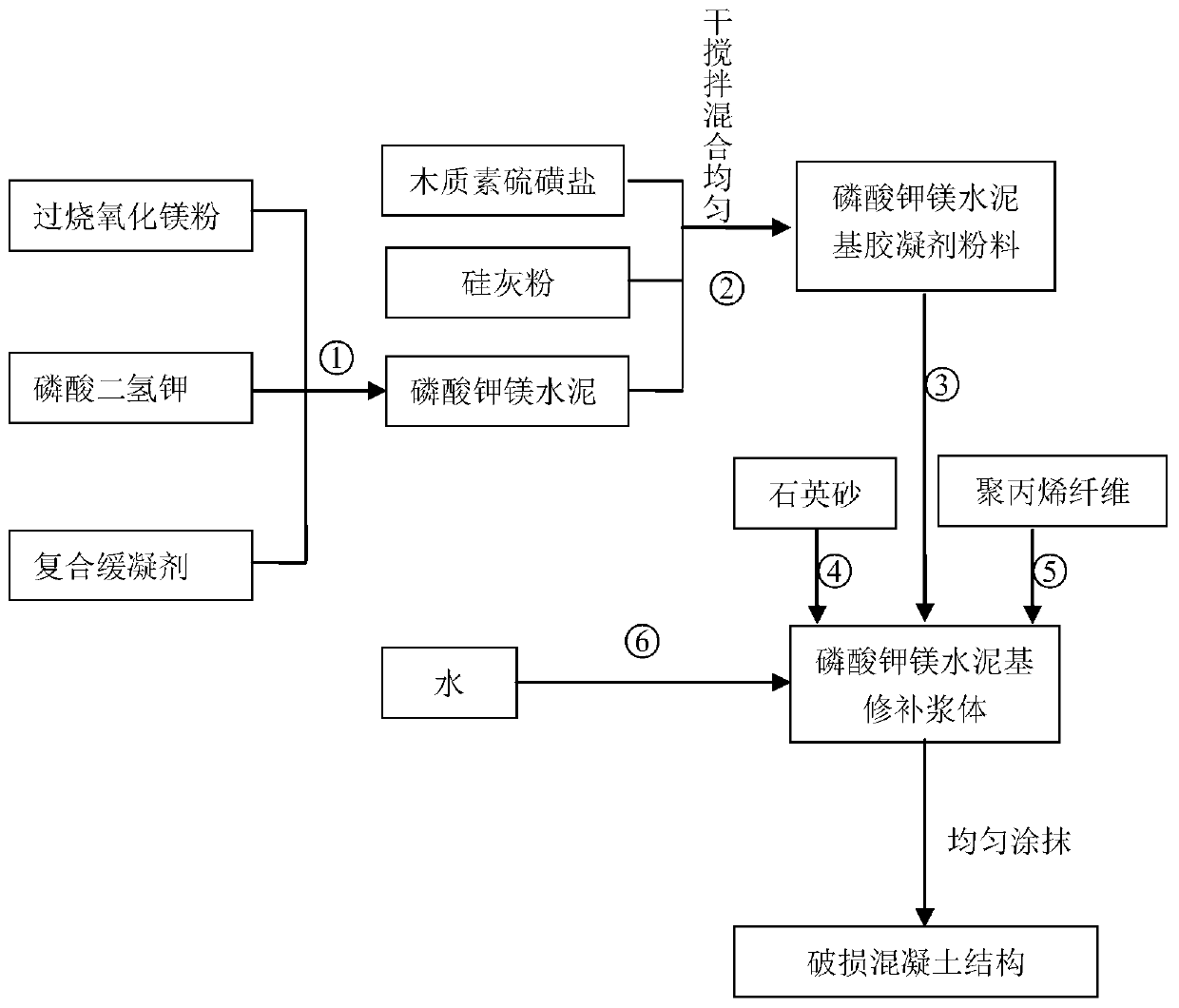

Method used

Image

Examples

Embodiment 1

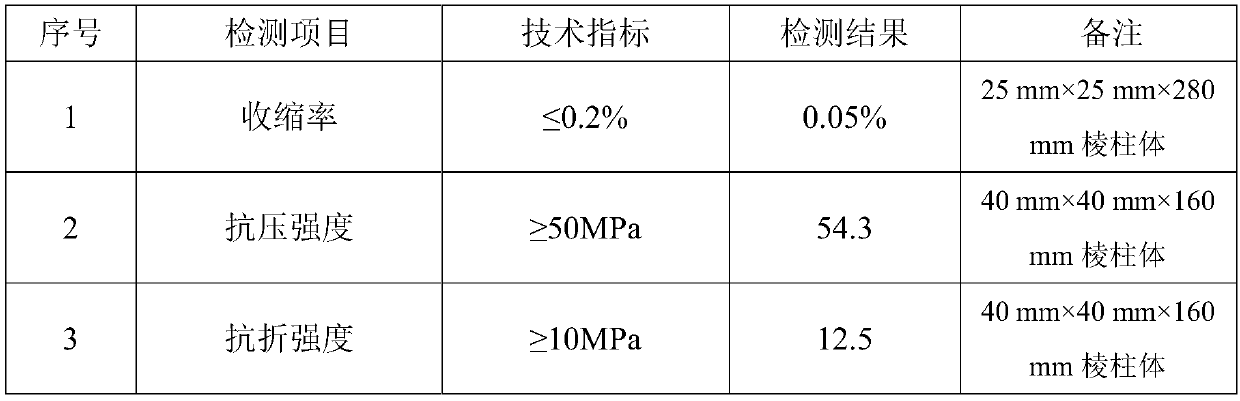

[0031] A potassium magnesium phosphate cement-based rapid repair material, which is mixed with potassium magnesium phosphate cement-based gelling agent powder, filling aggregate (quartz sand), polypropylene fiber and water:

[0032] Potassium magnesium phosphate cement-based adhesive powder is calculated by mass percentage: 63% of overburned magnesium oxide, 19% of potassium dihydrogen phosphate, 9.3% of composite retarder, 8.4% of silica fume powder, and 0.3% of wood sulfur salt; The retarder is composed of borax, disodium hydrogen phosphate dodecahydrate, inorganic chloride salt and polyphosphate, and the mass percentage of each component is 22:46:32; among them, the inorganic chloride salt and polyphosphoric acid in the composite retarder The mass ratio of salt is 2:3, magnesium chloride is selected as inorganic chlorine salt, and sodium polyphosphate is selected as polyphosphate.

[0033] The mass fraction of the overburned magnesium oxide powder is 95%, and the specific s...

Embodiment 2

[0045] A potassium magnesium phosphate cement-based rapid repair material, which is mixed with potassium magnesium phosphate cement-based gelling agent powder, filling aggregate (quartz sand), polypropylene fiber and water:

[0046] Wherein, the composition and content of potassium magnesium phosphate cement-based adhesive powder are the same as in Example 1. The difference is that the dry material of potassium magnesium phosphate cement repair material is calculated by mass fraction: 58% of potassium magnesium phosphate cement-based gelling agent powder, 41% of quartz sand, and 1.0% of PVC fiber. The mass ratio of inorganic chloride salt and polyphosphate in the composite retarder is 1:1, potassium chloride is selected for inorganic chloride salt, and sodium polyphosphate is selected for polyphosphate.

[0047] The preparation method and application method of the potassium magnesium phosphate cement-based repair slurry in Example 2 are the same as in Example 1.

[0048] Acco...

Embodiment 3

[0053] A potassium magnesium phosphate cement-based rapid repair material, which is mixed with potassium magnesium phosphate cement-based gelling agent powder, filling aggregate (quartz sand), polypropylene fiber and water:

[0054] Potassium magnesium phosphate cement-based adhesive powder is calculated by mass fraction: 62% of overburned magnesium oxide, 23% of potassium dihydrogen phosphate, 7.9% of composite retarder, 6.8% of silica fume powder, and 0.3% of lignosulfur salt;

[0055] The mass ratio of inorganic chloride salt and polyphosphate in the composite retarder is 1:1, magnesium chloride is selected for inorganic chloride salt, and sodium polyphosphate is selected for polyphosphate.

[0056] The dry material of potassium magnesium phosphate cement repair material is calculated by mass fraction: 60% of potassium magnesium phosphate cement-based gelling agent powder, 39% of quartz sand, and 1.0% of PVC fiber.

[0057] The preparation method and application method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com