High-fluorine low-zirconium type melting welding agent for ship and preparation method thereof

A technology for smelting flux and high fluorine, which is applied in the field of marine high-fluorine and low-zirconium smelting flux and its preparation, can solve the problems of difficult to obtain high-toughness weld metal, high diffusible hydrogen content and high activity of weld metal, and achieve good Uniform chemical composition, uniform weld metal composition, low moisture absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

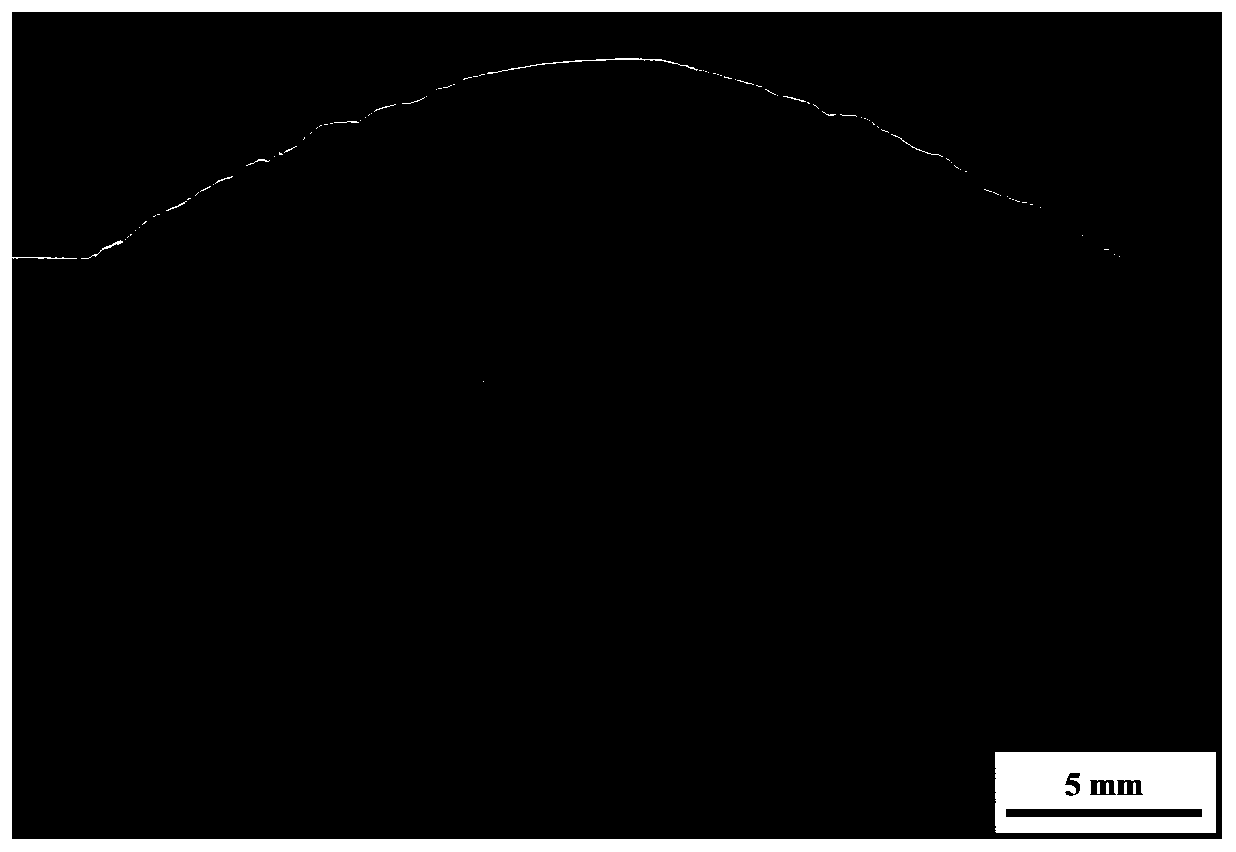

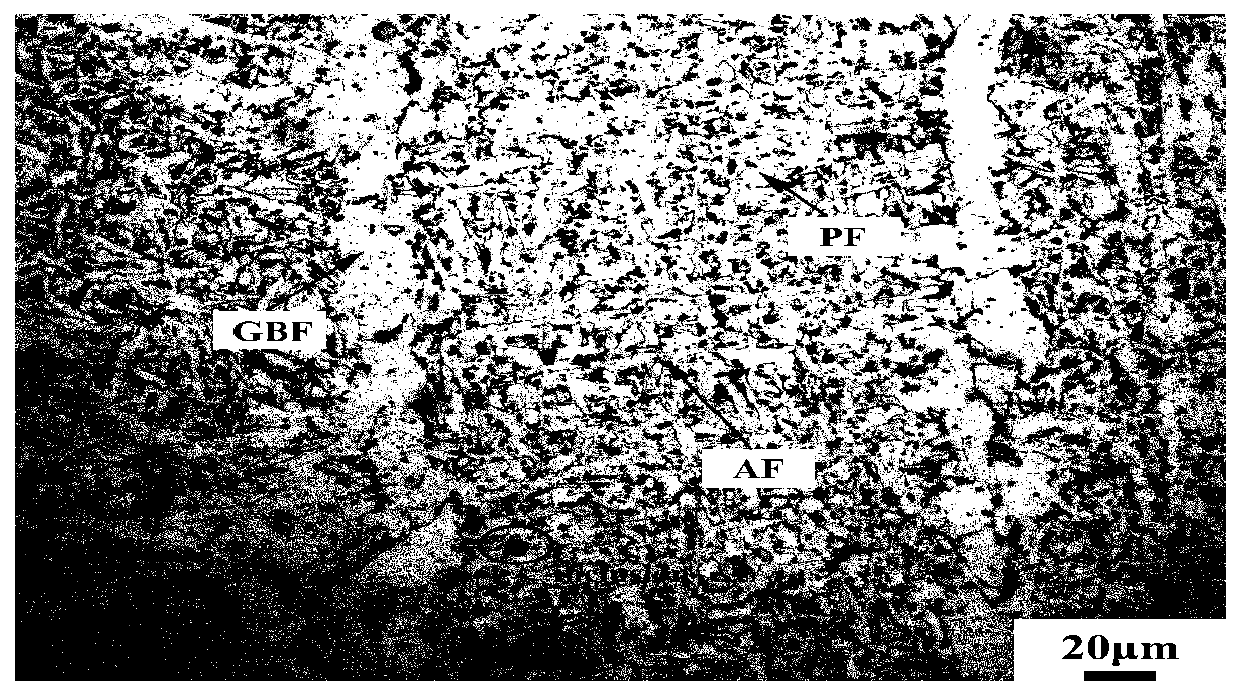

Image

Examples

Embodiment 1

[0038] A marine high-fluorine and low-zirconium melting flux, which contains the following components by mass percentage: CaF 2 : 97%, ZrO 2 :3%.

[0039] The preparation method of the marine high-fluorine and low-zirconium type smelting flux of the present invention comprises the following steps:

[0040] Step 1, smelting:

[0041] (1) According to the proportion of high-fluorine and low-zirconium melting flux for marine use, weigh the raw material CaF of each component 2 , ZrO 2 , put each raw material into the mixing equipment, and mix evenly by stirring;

[0042] (2) smelting the homogeneously mixed raw materials in a graphite crucible at 1540° C., and the smelting holding time is 15 minutes to obtain a smelted product;

[0043] (3) Quenching the smelted product with water to obtain a semi-finished product;

[0044] Step 2, high temperature roasting:

[0045] The semi-finished product was roasted at 800°C for 2 hours in a muffle furnace to obtain a roasted product, ...

Embodiment 2

[0050] A marine high-fluorine and low-zirconium melting flux, which contains the following components by mass percentage: CaF 2 : 95%, ZrO 2 :5%.

[0051] The preparation method of the marine high-fluorine and low-zirconium type smelting flux of the present invention comprises the following steps:

[0052] Step 1, smelting:

[0053] (1) According to the proportion of high-fluorine and low-zirconium melting flux for marine use, weigh the raw material CaF of each component 2 , ZrO 2 , put each raw material into the mixing equipment, and mix evenly by stirring;

[0054] (2) Melting the homogeneously mixed raw materials in a graphite crucible at 1520° C., the smelting holding time is 20 minutes, and the smelting product is obtained;

[0055] (3) Quenching the smelted product with water to obtain a semi-finished product;

[0056] Step 2, high temperature roasting:

[0057] The semi-finished product was roasted at 800°C for 2 hours in a muffle furnace to obtain a roasted prod...

Embodiment 3

[0062] A marine high-fluorine and low-zirconium melting flux, which contains the following components by mass percentage: CaF 2 : 96%, ZrO 2 :4%.

[0063] The preparation method of the marine high-fluorine and low-zirconium type smelting flux of the present invention comprises the following steps:

[0064] Step 1, smelting:

[0065] (1) According to the proportion of high-fluorine and low-zirconium melting flux for marine use, weigh the raw material CaF of each component 2 , ZrO 2 , put each raw material into the mixing equipment, and mix evenly by stirring;

[0066] (2) Melting the homogeneously mixed raw materials in a graphite crucible at 1560° C., and the smelting holding time is 10 minutes to obtain a smelted product;

[0067] (3) Quenching the smelted product with water to obtain a semi-finished product;

[0068] Step 2, high temperature roasting:

[0069] The semi-finished product was roasted at 800°C for 2 hours in a muffle furnace to obtain a roasted product, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com