Seedless particles with carbon allotropes

A carbon allotrope, carbon nanoparticle technology, applied in nanocarbon, inorganic chemistry, carbon compounds, etc., can solve the problems of high cost and difficult to collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

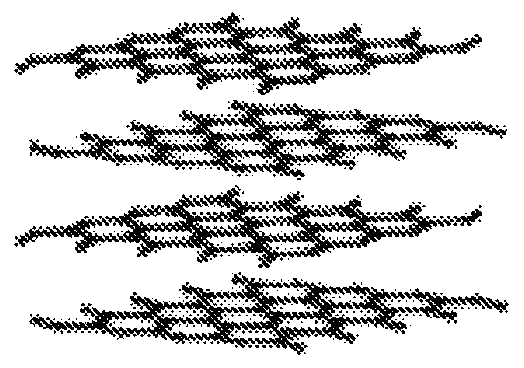

[0130] Example 1: Graphite and Graphene Particles Produced Using a Microwave Plasma Reactor

[0131] In this first example, carbon particles and aggregates containing graphite and graphene were produced using the microwave plasma reactor system described in the previous embodiments. The microwave plasma reactor in this example has a main body made of stainless steel and a quartz inner wall material. However, a quartz inner wall material is not required in all cases and similar carbon materials can be produced in a quartz-free reactor in or adjacent to the reaction zone. The reaction zone volume is about 45 cm 3 . The precursor material is methane, optionally mixed with a supply gas such as argon. The flow rate of methane is 1 to 20 L / min, and the flow rate of the supply gas is 0 to 70 L / min. With these flow rates and tool geometries, the gas residence time in the reaction chamber is from about 0.001 seconds to about 2.0 seconds, and the carbon particle production rate is f...

Embodiment 2

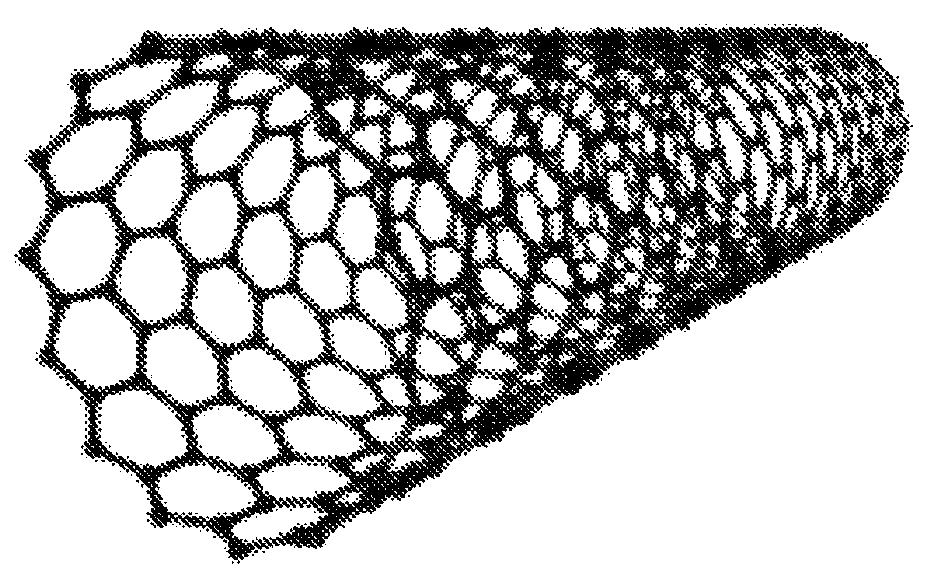

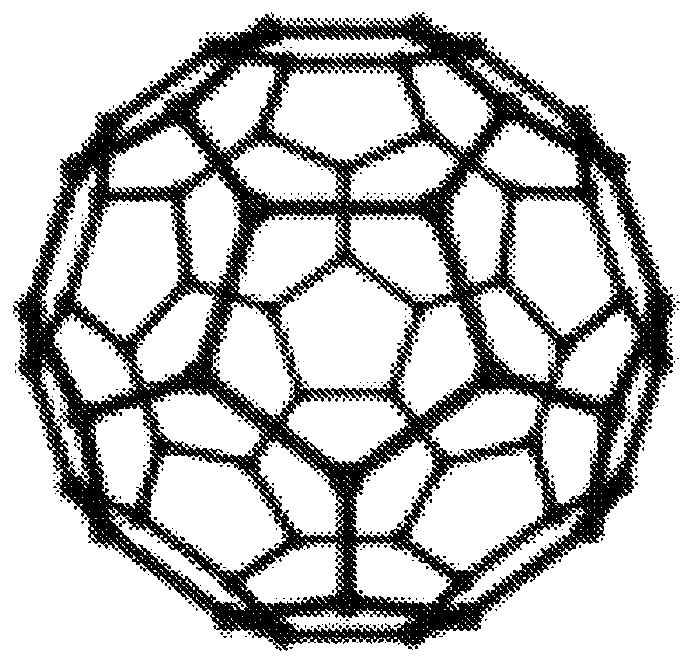

[0139] Example 2: Graphite, graphene and multi-walled spherical fullerene particles produced using a microwave plasma reactor

[0140]In this second example, carbon particles containing graphite, graphene, MWSF and attached MWSF were produced using the microwave plasma reactor system described in Example 1 by adding filaments comprising tantalum / tungsten resistive wires and Aggregates. The precursor material is methane, optionally mixed with a supply gas such as argon. The flow rate of methane is 1 to 100 L / min, and the flow rate of the supply gas is 0 to 100 L / min. With these flow rates and tool geometries, the gas residence time in the reaction chamber is from about 0.001 seconds to about 2.0 seconds, and the carbon particle production rate is from about 0.1 g / hour to about 15 g / hour. After the aggregate is synthesized and collected, the aggregate is post-treated by annealing at a temperature of 1000°C to 2200°C for about 60 to about 600 minutes in an inert atmosphere.

...

Embodiment 3

[0148] Example 3: Graphite, Graphene and Amorphous Carbon Particles Produced Using a Microwave Plasma Reactor

[0149] In this third example, carbon particles and aggregates containing graphite, graphene, and amorphous carbon were produced using a microwave plasma reactor system as described in Example 1. The precursor material contains methane, or isopropanol (IPA), or ethanol, or condensed hydrocarbons such as hexane. A carbon-containing precursor is optionally mixed with a supply gas such as argon. When gaseous methane is used, the flow rate of methane is 1 to 20 L / min, and the flow rate of supply gas is 0 to 70 L / min. When the precursor material is a liquid mixture of IPA and ethanol, the flow rate of the liquid mixture is 0.1 to 100 mL / minute. In some other cases, condensing hydrocarbons were used and the flow rate of the hydrocarbons was about 3 L / min. With these flow rates and tool geometries, the gas residence time in the reaction chamber is from about 0.001 seconds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com