Antifoaming agent and lubricant composition

A defoamer and polymer technology, which is applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as increased foaming, accelerated deterioration of lubricating oil, poor oil pressure control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

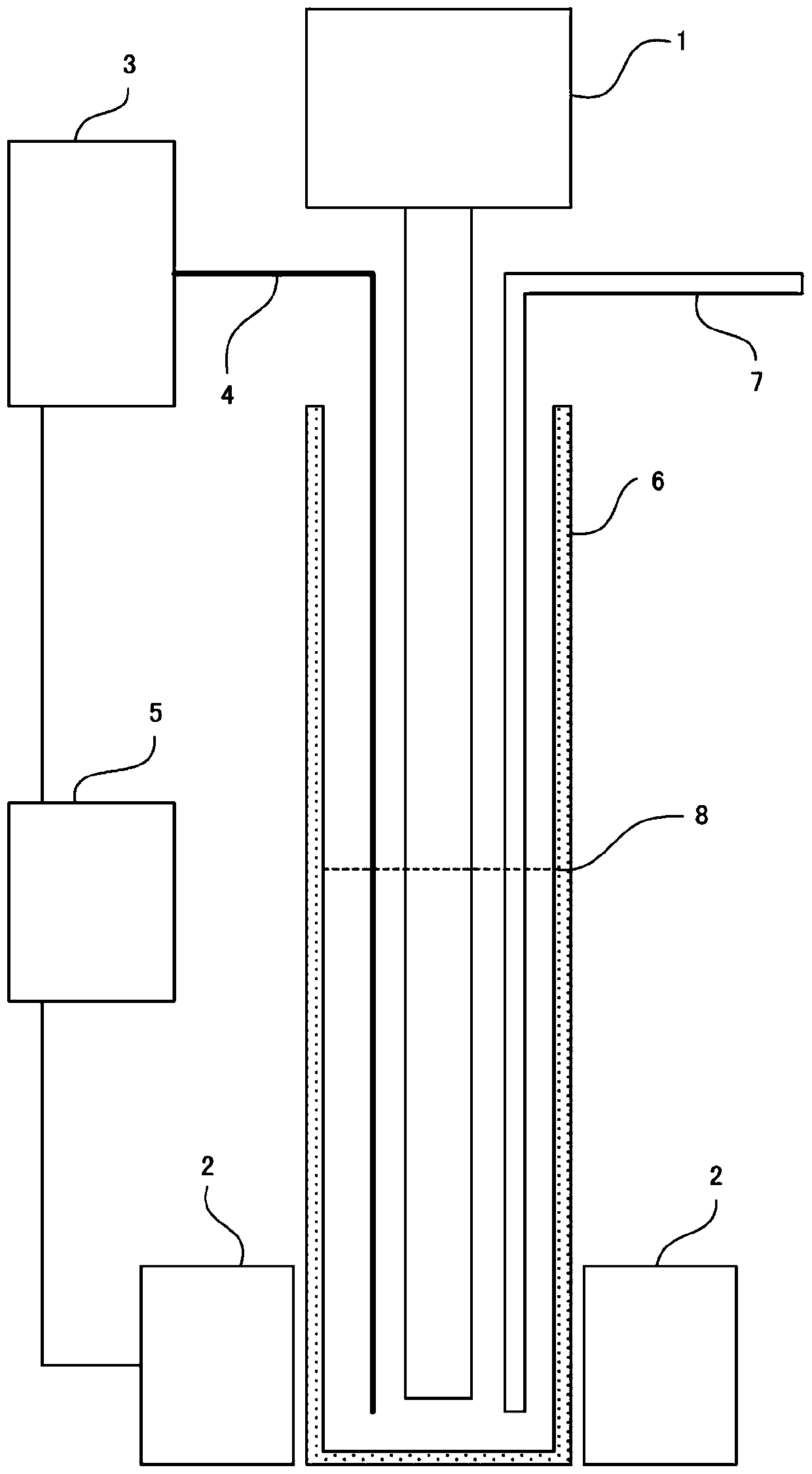

Image

Examples

Embodiment

[0324] Hereinafter, the present invention will be described in more detail based on Examples and Comparative Examples. However, the following examples show examples of the present invention and are not intended to limit the present invention.

[0325]

[0326] (Determination of molecular weight and molecular weight distribution)

[0327] In the following manufacturing examples and examples, with regard to molecular weight and molecular weight distribution, a GPC device (HLC manufactured by TOSOH CORPORATION) connected in series with 3 columns (TSKgel Super MultiPore HZ-M manufactured by TOSOH CORPORATION, inner diameter 4.6mm×15cm) -8220), using tetrahydrofuran as the mobile phase and differential refractometer (RI) as the detector, under the conditions of measuring temperature 40°C, flow rate 0.35mL / min, sample concentration 1% by mass, and sample injection volume 5μL , Use polystyrene as the standard material for determination.

manufacture example 1

[0329] According to the following steps, the antifoaming agent A according to the first aspect of the present invention is manufactured.

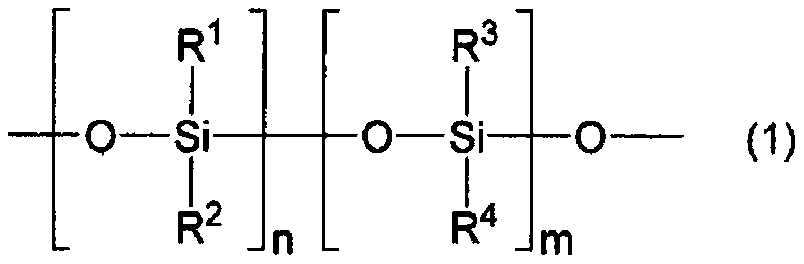

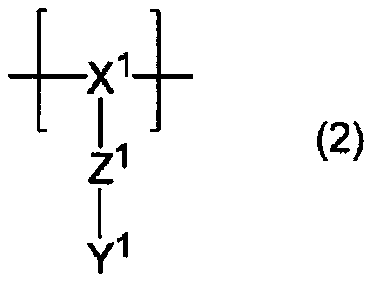

[0330] Into a 500 mL four-neck flask equipped with a PTFE stirring blade (with a vacuum seal), a Dimro reflux condenser, a three-way stopcock for nitrogen introduction, and a sample introduction port, methyl isobutyl ketone (polymerization Solvent) 200 parts by mass, and 5 parts by mass of polysiloxane macromonomer represented by the following general formula (25) (manufactured by Shin-Etsu Chemical Co., Ltd., weight average molecular weight 43,000, polydispersity index (Mw / Mn) 1.50) 95 parts by mass of lauryl methacrylate and 95 parts by mass of lauryl methacrylate were made into a homogeneous mixture under stirring, and then vacuum degassing and nitrogen replacement of the reaction system were performed 5 times using a diaphragm pump. Under nitrogen flow, introduce MAIB (dimethyl 2,2'-azobisisobutyrate: dimethyl 2,2'-azobisisobutyrate, azo r...

manufacture example 2

[0333] According to the following steps, the defoamer B according to the first aspect of the present invention is manufactured.

[0334] Into a 500 mL four-neck flask equipped with a PTFE stirring blade (with a vacuum seal), a Dimro reflux condenser, a three-way stopcock for nitrogen introduction, and a sample introduction port, methyl isobutyl ketone (polymerization Solvent) 200 parts by mass, and 20 parts by mass of polysiloxane macromonomer represented by the following general formula (25) (manufactured by Shin-Etsu Chemical Co., Ltd., weight average molecular weight 43,000, polydispersity index (Mw / Mn) 1.50) 80 parts by mass of lauryl methacrylate and 80 parts by mass of lauryl methacrylate were made into a homogeneous mixture under stirring, and then vacuum degassing and nitrogen replacement of the reaction system were performed 5 times using a diaphragm pump. Under nitrogen flow, introduce MAIB (dimethyl 2,2'-azobisisobutyrate: dimethyl 2,2'-azobisisobutyrate, azo radical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com