A kind of preparation method of low defoaming silicon dioxide

A silicon dioxide and defoaming technology, applied in chemical instruments and methods, cosmetic preparations, medical preparations containing active ingredients, etc., to achieve the effects of reduced adsorption, controllable conditions, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

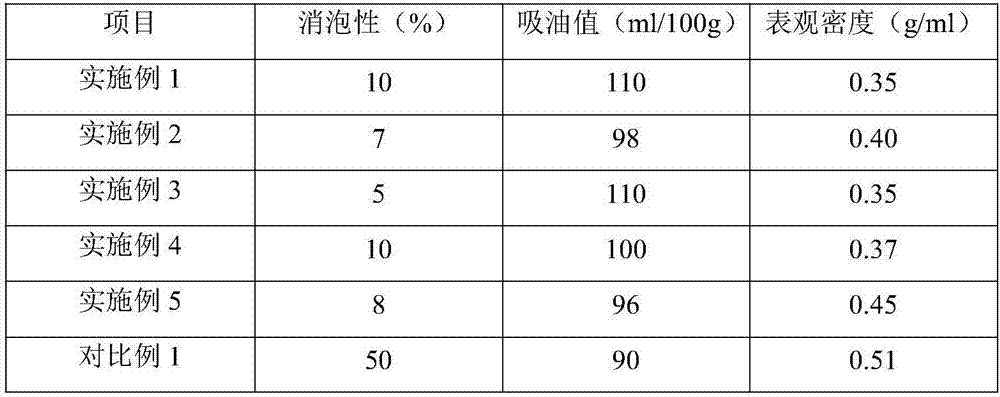

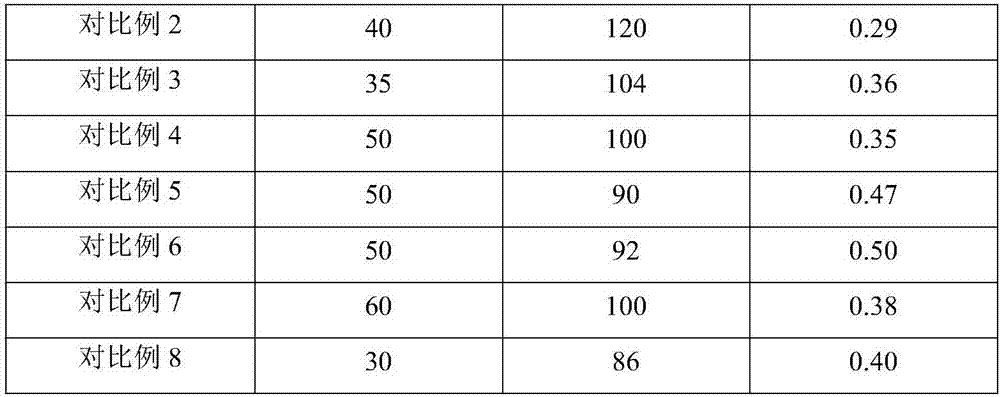

Examples

Embodiment 1

[0026] Embodiment 1, the preparation method of low defoaming silica of the present invention

[0027] S1, add 5m into the reactor 3 Sodium sulfate solution, start stirring, then add 1.0kg composite surfactant, stir evenly and heat to 60°C;

[0028] S2, at 10m 3 Add 6m into the reactor at a flow rate of / h 3 Sodium silicate solution, add sulfuric acid solution to the reaction kettle after adding sodium silicate solution for half a minute, adjust the adding speed of sulfuric acid solution to control the pH value of the reaction process to 9.0, continue to add sulfuric acid solution after adding sodium silicate solution, until The pH value at the end of the reaction is 4.0, and the addition of sulfuric acid solution is stopped;

[0029] S3. Maintain 60° C., continue to stir for 10 minutes, press filter and wash the formed silica precipitate, dry and pulverize the washed silica to obtain low defoaming silica.

[0030] The composite surfactant is a composition of sodium dodecyl...

Embodiment 2

[0034] Embodiment 2, the preparation method of low defoaming silica of the present invention

[0035] S1, add 10m 3 Sodium sulfate solution, start stirring, then add 3.0kg composite surfactant, stir evenly and heat to 70°C;

[0036] S2, at 15m 3 Add 11m to the reactor at a flow rate of / h 3 Sodium silicate solution, add sulfuric acid solution to the reaction kettle after adding sodium silicate solution for half a minute, adjust the adding speed of sulfuric acid solution to control the pH value of the reaction process to 9.5, continue to add sulfuric acid solution after adding sodium silicate solution, until The pH value at the end of the reaction is 5.0, and the addition of sulfuric acid solution is stopped;

[0037] S3. Keep at 70° C., continue to stir for 15 minutes, press filter and wash the formed silica precipitate, dry and pulverize the washed silica to obtain low defoaming silica.

[0038] Described composite surfactant is the composition of fatty alcohol polyoxyeth...

Embodiment 3

[0042] Embodiment 3, the preparation method of low defoaming silica of the present invention

[0043] S1, add 8m into the reactor 3 Sodium sulfate solution, start stirring, then add 2.0kg composite surfactant, stir evenly and heat to 65°C;

[0044] S2, with 12m 3 Add 9m into the reactor at a flow rate of / h 3 Sodium silicate solution, add sulfuric acid solution to the reaction kettle after adding sodium silicate solution for half a minute, adjust the adding speed of sulfuric acid solution to control the pH value of the reaction process to 9.0, continue to add sulfuric acid solution after adding sodium silicate solution, until The pH value at the end of the reaction is 4.5, stop adding sulfuric acid solution;

[0045] S3. Maintain 65° C., continue to stir for 10 minutes, press filter and wash the formed silica precipitate, dry and pulverize the washed silica to obtain low defoaming silica.

[0046] Described composite surfactant is the composition of fatty alcohol polyoxyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com