Method for separating and quantitatively analyzing food-borne nanoparticles

A technology for quantitative analysis of nanoparticles, applied in particle and sedimentation analysis, particle size analysis, analysis of materials, etc., can solve the problems of inability to quantitatively analyze and elute food-borne nanoparticles, achieve low detection limit, high sensitivity, Effect of small injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Separation and collection of river clam soup nanoparticles by capillary electrophoresis

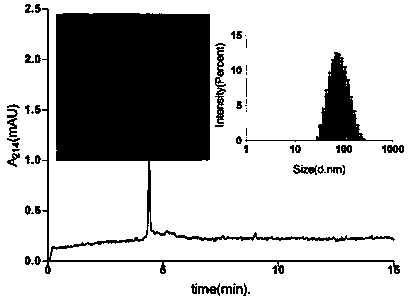

[0042] Take 1 mg of clam soup freeze-dried powder and prepare a solution with a concentration of 1 mg / mL with 1 mL of pure water, collect it by capillary electrophoresis, set the program according to the peak time of nanoparticles, repeat the experiment for 30 rounds, and collect it in a sample bottle. First, the collected samples were taken with a transmission electron microscope, and the results were as follows: figure 1 (Ⅰ). The collected samples were then measured using a Malvern laser particle size analyzer, and the results were as follows Figure 2-8 (II).

[0043] The results showed that the average particle size of the collected samples was 68.4nm, which was consistent with the particle size of nanoparticles separated by ultrafiltration and dialysis. Therefore, it was confirmed that capillary electrophoresis can separate the nanoparticles of clam soup.

Embodiment 2

[0044] Example 2: Quantitative analysis of functional nanoparticles in river clam soup

[0045] Including the following steps:

[0046] (1) Thermal processing, centrifugation, and freeze-drying to obtain functional nano-particle freeze-dried powder in river clam soup

[0047] Wash the clam with distilled water and rest for more than 5 hours, weigh the fresh individual, add distilled water according to the ratio of solid to liquid 1:2kg / L and boil for 1 hour, then cool to room temperature, and finally filter with gauze to obtain the clam soup.

[0048] The clam soup is then centrifuged at a speed of 8000r·min -1 , centrifuged for 15 min to obtain the supernatant.

[0049] Finally, the supernatant was pre-frozen at -80°C for 0.5-3h, and then transferred to a vacuum freeze dryer for 2-3d. Freeze-dry the supernatant to obtain freeze-dried powder.

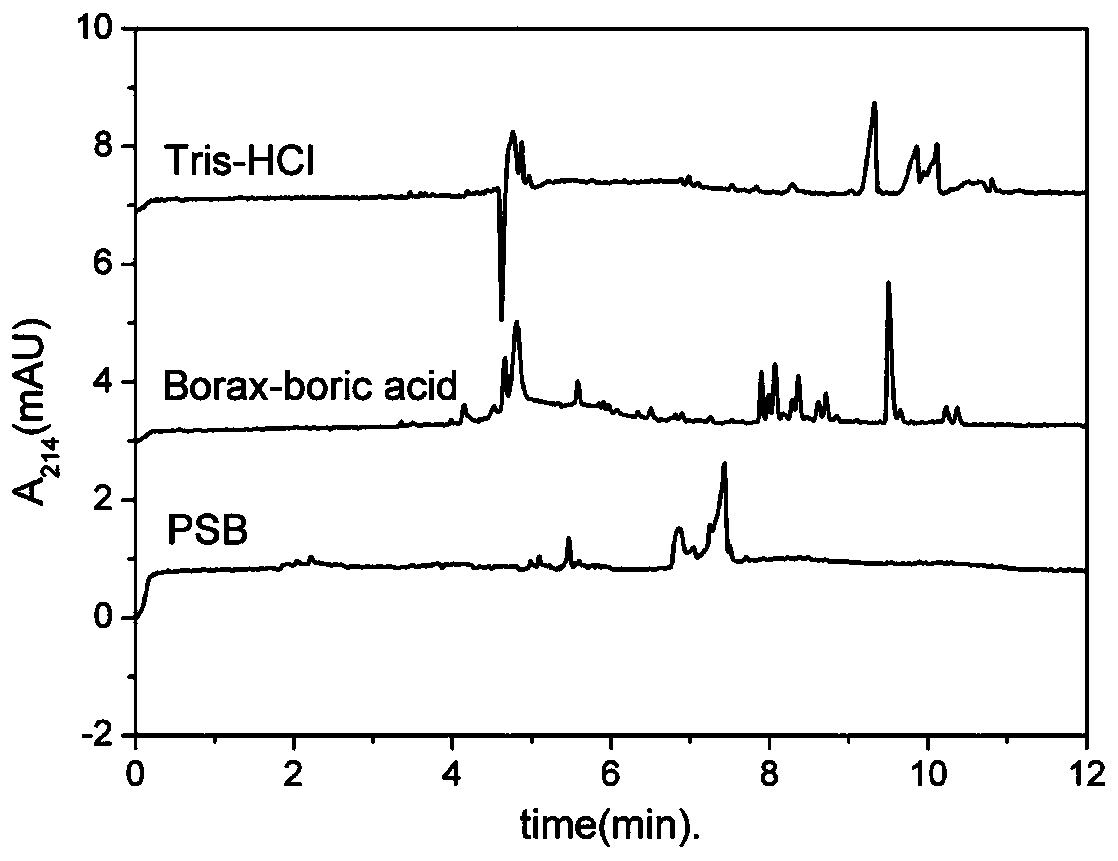

[0050] (2) Preparation of samples and separation of functional nanoparticles by capillary electrophoresis

[0051] The lyophilized ...

Embodiment 3

[0055] Example 3: Detecting the Effect of Ultraviolet Wavelength

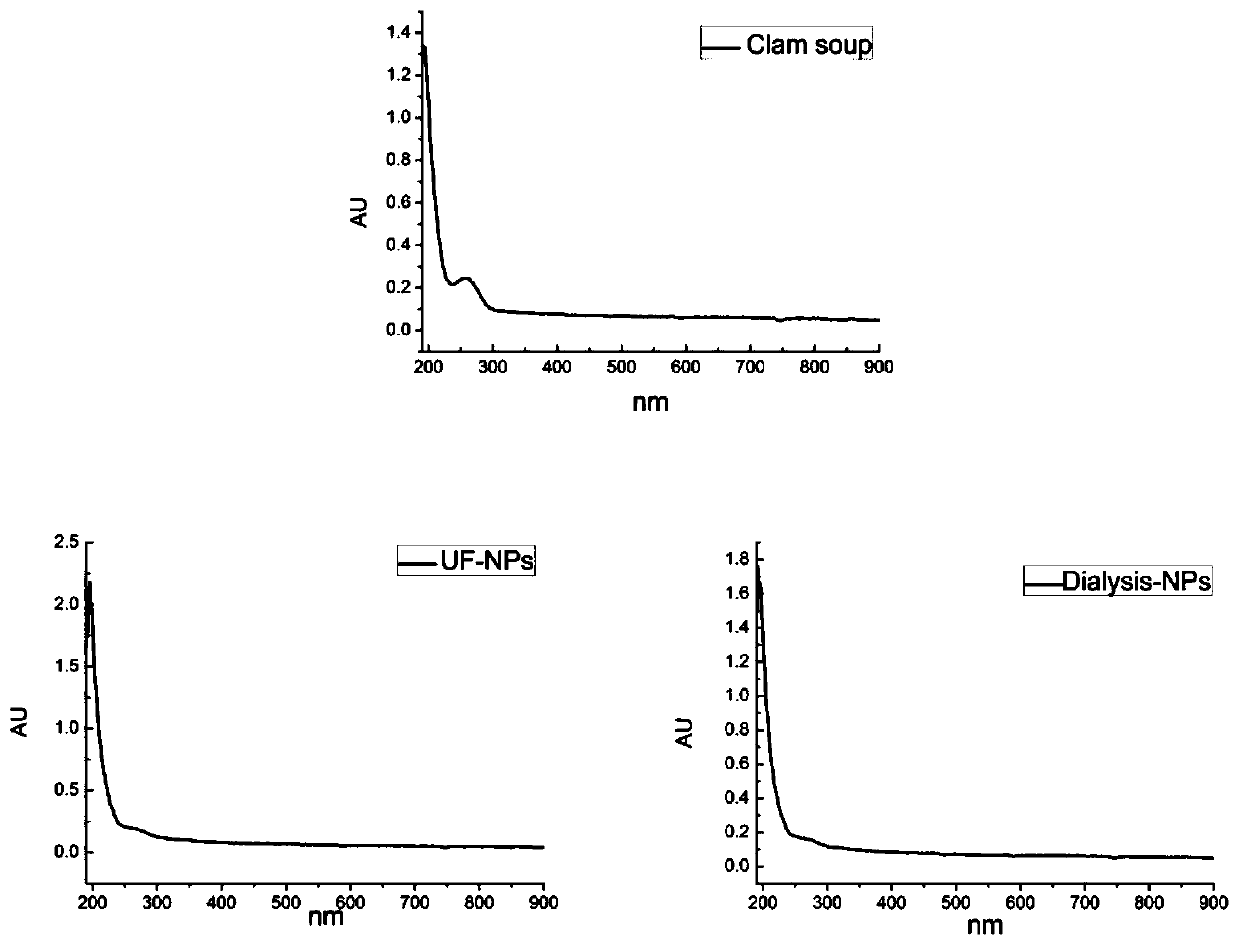

[0056] Take one portion each of 1mg clam original soup freeze-dried powder, ultrafiltration cut-off particle freeze-dried powder and dialysis particle freeze-dried powder, respectively prepare a solution with a concentration of 1mg / mL with 1mL pure water, place it in a quartz cuvette, and at the same time , take 1mL pure water as a blank control. Measure the absorbance of the sample solution at 190-900nm to determine the wavelength corresponding to the maximum absorption peak of the original soup and its separated nanomicelle. The results are as follows figure 2 show.

[0057] The results show that when the absorption wavelength is 214nm, the absorbance value of the sample solution is the largest, except that the original solution of river clam soup has two larger absorbance values, and the prepared nanoparticles have no interference from other impurities. Therefore, the determination of nanomicelle The sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com