Boron phosphide single crystals and preparation method and application thereof

A technology of boron phosphide and single crystal, which is applied in the field of boron phosphide single crystal and its preparation, can solve the problems of toxic hazards of reactants and difficult preparation, and achieve the effects of less defects, good application prospects and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

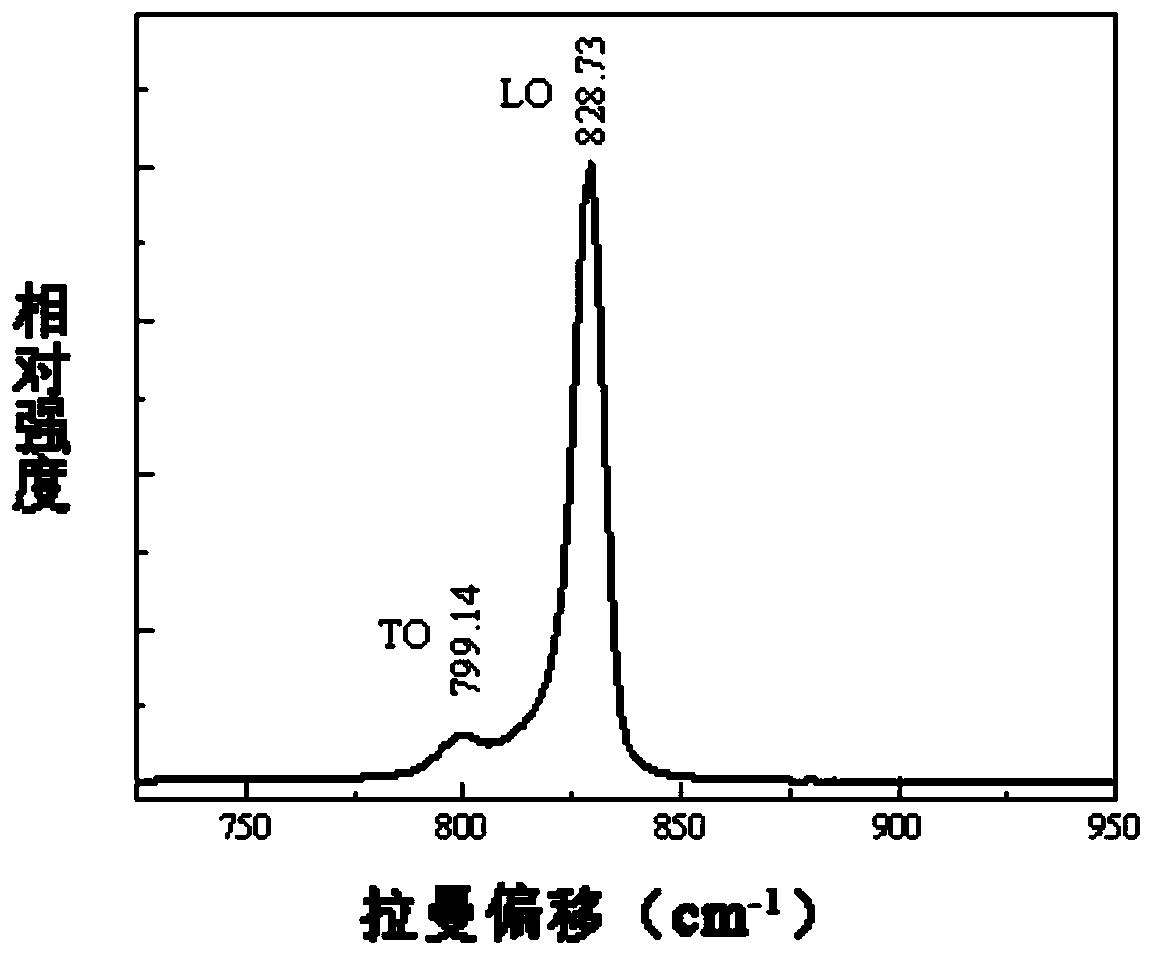

Image

Examples

Embodiment 1

[0062] This embodiment prepares boron phosphide single crystal according to the following method:

[0063] (1) Weigh boron powder, red phosphorus and nickel powder according to the molar ratio of 1:1:2.5, then put them into an agate mortar for grinding and mixing, put the obtained mixture into a quartz tube, and then connect to a vacuum Sealing machine, slowly pumping to a vacuum of 10 -3 Pa, use a high-temperature flame spray gun to heat and melt the neck of the quartz tube and the quartz plug in a vacuum environment, and solidify and seal after cooling;

[0064] (2) placing the sealed container in step (1) in a tube furnace, warming up to 1200°C for 1000min with a heating rate of 5°C / min, then cooling to 1100°C with a cooling rate of 0.05°C / min , and then continue to cool down at a cooling rate of 5°C / min, and cool down to 25°C to obtain a reaction product;

[0065] (3) Take out the sealed container from the tube furnace, cut the quartz tube with a cutting machine, take ou...

Embodiment 2

[0070] This embodiment prepares boron phosphide single crystal according to the following method:

[0071] (1) Weigh boron powder, red phosphorus and nickel powder according to the molar ratio of 1.1:1.1:2, then put them into an agate mortar for grinding and mixing, put the obtained mixture into a quartz tube, and then connect to a vacuum Sealing machine, slowly pumping to a vacuum of 5 × 10 -4 Pa, use a high-temperature flame spray gun to heat and melt the neck of the quartz tube and the quartz plug in a vacuum environment, and solidify and seal after cooling;

[0072] (2) placing the sealed container in step (1) in a tube furnace, warming up to 1180°C for 1100min at a heating rate of 4°C / min, then cooling to 1150°C with a cooling rate of 0.04°C / min , and then continue to cool down at a cooling rate of 4°C / min, and cool down to 35°C to obtain a reaction product;

[0073] (3) Take out the sealed container from the tube furnace, cut the quartz tube with a cutting machine, tak...

Embodiment 3

[0076] This embodiment prepares boron phosphide single crystal according to the following method:

[0077] (1) Weigh boron powder, red phosphorus and nickel powder according to the molar ratio of 0.9:0.9:3, then put them into an agate mortar for grinding and mixing, put the obtained mixture into a quartz tube, and then connect to a vacuum Sealing machine, slowly pumping to a vacuum of 10 - 4 Pa, use a high-temperature flame spray gun to heat and melt the neck of the quartz tube and the quartz plug in a vacuum environment, and solidify and seal after cooling;

[0078] (2) placing the sealed container in step (1) in a tube furnace, warming up to 1190°C for 900min at a heating rate of 6°C / min, then cooling to 1120°C with a cooling rate of 0.06°C / min , and then continue to cool down at a cooling rate of 6°C / min, and cool down to 15°C to obtain a reaction product;

[0079] (3) Take out the sealed container from the tube furnace, cut the quartz tube with a cutting machine, take o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com