Organic adhesive used in waste ash processing, and preparation equipment thereof

An organic adhesive and equipment technology, applied in the field of organic adhesives and preparation equipment, can solve the problem of high cost of waste ash treatment, and achieve the effects of good thermal stability, good thermal stability, excellent solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: An organic binder for waste ash treatment, including sulfur monoxide, sodium hypochlorite, tackifier, reducing agent and strengthening agent, characterized in that the sulfur monoxide is 10 parts to 20 parts, Sodium hypochlorite is 5 parts to 8 parts, the reinforcing agent is prepared by mixing coal tar, and the reinforcing agent includes the following materials by weight: 10 parts to 20 parts of coal tar are mixed and prepared;

[0028] The tackifier is 5 to 15 parts of xanthan gum, which is also known as xanthan gum. The appearance of xanthan gum is white powder, the particle size is 80 meshes without sieve, and xanthan gum is one percent solution. The viscosity is 0.6Pa.S~1Pa.S. Xanthan gum is an anionic polymer polysaccharide polymer produced by fermentation of starch;

[0029] The reducing agent is 5-10 parts formamidine sulfinic acid;

[0030] 2 to 5 parts of LiAlH are also added to the binder 4 ;

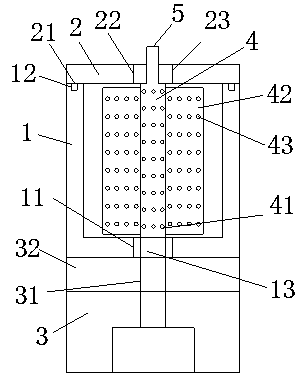

[0031] See Figure 1-3 , An organic adhesive preparation equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com