Thermoplastic elastomer with both electrical conductivity and flame retardancy and preparation method thereof

A thermoplastic elastomer, flame-retardant technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of product mechanical strength decline, poor temperature resistance, intolerance to strong polar solvents and strong acid-base media, etc., to achieve strong electrical conductivity The effect of stability, good mechanical strength and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

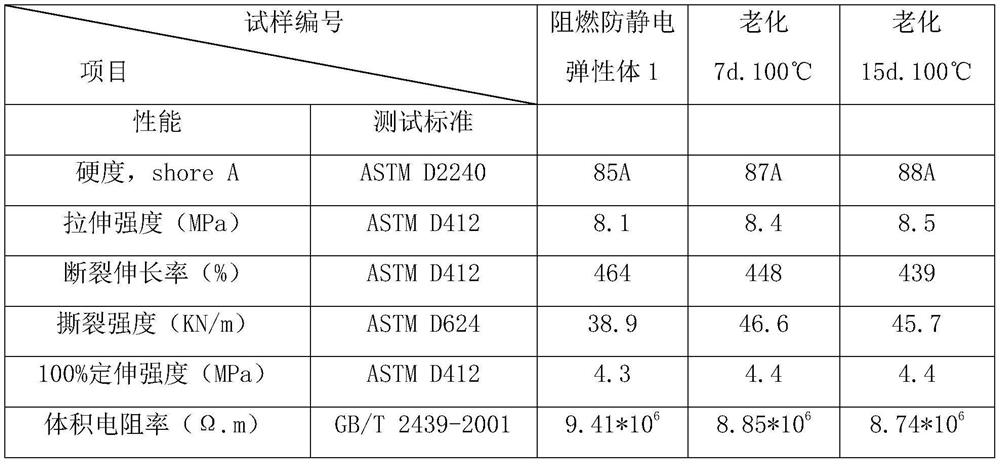

Examples

Embodiment 1

[0045] The preparation method of thermoplastic elastomer with both electrical conductivity and flame retardancy is as follows:

[0046] a), measure according to weight ratio, firstly take 1 part of coupling agent, put it into ethanol solution, stir and mix, and adjust PH to be weakly alkaline, make it hydrolyzed, then take 16 parts of conductive medium, described The DBP absorption value of conductive carbon black is 170-185ml / g, the iodine absorption value is 360Mg / g, and the particle size is 9-17nm. Carbon content≥95%, volume resistivity≤1.5*10 -3 Ω.cm. Add in it and stir, then heat in a water bath to volatilize ethanol to obtain a pretreated mixed conductive medium, then weigh 10 parts of random polypropylene into a high-speed mixer, and the polypropylene melt flow rate is 16±3. Then add 10 parts of conductive carbon black, add 0.1 part of stabilizer, 0.1 part of antioxidant, stir for one minute, finally add 0.4 part of lubricant, knead for one minute and then process and...

Embodiment 2

[0051] The preparation method of thermoplastic elastomer with both electrical conductivity and flame retardancy is as follows:

[0052] a), measure according to weight ratio, firstly take 1 part of coupling agent, put it into ethanol solution, stir and mix, and adjust PH to be weakly alkaline, make it hydrolyzed, then take 16 parts of conductive medium, described The DBP absorption value of conductive carbon black is 170-185ml / g, the iodine absorption value is 360Mg / g, and the particle size is 9-17nm. Carbon content≥95%, volume resistivity≤1.5*10 -3 Ω.cm. Add in it and stir, then heat in a water bath to volatilize ethanol to obtain a pretreated mixed conductive medium, then weigh 10 parts of random polypropylene into a high-speed mixer, and the polypropylene melt flow rate is 16±3. Then add 10 parts of conductive carbon black, add 0.1 part of stabilizer, 0.1 part of antioxidant, stir for one minute, finally add 0.4 part of lubricant, knead for one minute and then process and...

Embodiment 3

[0058] The preparation method of thermoplastic elastomer with both electrical conductivity and flame retardancy is as follows:

[0059] a), measure according to weight ratio, firstly take 1 part of coupling agent, put it into ethanol solution, stir and mix, and adjust PH to be weakly alkaline, make it hydrolyzed, then take 16 parts of conductive medium, described The DBP absorption value of conductive carbon black is 170-185ml / g, the iodine absorption value is 360Mg / g, and the particle size is 9-17nm. Carbon content≥95%, volume resistivity≤1.5*10 -3 Ω.cm. Add in it and stir, then heat in a water bath to volatilize ethanol to obtain a pretreated mixed conductive medium, then weigh 10 parts of random polypropylene into a high-speed mixer, and the polypropylene melt flow rate is 16±3. Then add 10 parts of conductive carbon black, add 0.1 part of stabilizer, 0.1 part of antioxidant, stir for one minute, finally add 0.4 part of lubricant, knead for one minute and then process and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com