Method for removing iopamidol in water by ultraviolet/chlorine combined process

A combined process and water removal technology, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problem of low safety and practicability of chloramine process, limited treatment effect, unstable removal rate, etc. It can improve the feasibility and operability, the method is simple and practical, and the reaction conditions are easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The method for removing iopamidol in water by ultraviolet / chlorine combined process, the concrete steps are as follows:

[0054] The initial concentration of iopamidol is 10 μM prepared with ultrapure water, the initial pH of the iopamidol solution is adjusted to 7.0 with acid-base solution, and sodium hypochlorite is added to the iopamidol solution, and the dosage is [HOC1] 0 = 200 μM (in C1 2 meter), and UV irradiation was carried out at the same time, and the UV intensity was controlled to be 2.43 mW / cm 2 , control the reaction temperature to 25 ℃.

[0055] In the single chlorination process (comparative example 1), the single ultraviolet process (comparative example 2) and the ultraviolet / chlorination combined process (embodiment 1), the iopamidol concentration curve with time is as follows: figure 1 As shown, it can be seen that the removal effect of iopamidol is different under different processes. The simultaneous action of UV / chlorine can greatly improve the ...

Embodiment 2

[0057] A method for removing iopamidol in water by an ultraviolet / chlorine combined process, the concrete steps are as follows:

[0058] The initial concentration of iopamidol was prepared with ultrapure water to 10 μM, the initial pH of iopamidol solution was adjusted to 7.0 with acid-base solution, and sodium hypochlorite was added to the iopamidol solution, and the dosage was controlled to [HOC1] 0 =0μM, 50μM, 100μM, 200μM, 500μM, 1000μM (with C1 2 meter), and UV irradiation was carried out at the same time, and the UV intensity was controlled to be 2.43 mW / cm 2 , the reaction temperature was controlled at 25°C during the reaction, and the removal rates of iopamidol after 300s of reaction were 43.72%, 84.71%, 96.16%, 97.90%, 98.10%, and 99.24%, respectively. figure 2 .

[0059] from figure 2 It can be seen that under the condition that the UV intensity remains unchanged, as the amount of chlorine increases, there will be more Cl in the system 2 , HOCl / OCl - Degradati...

Embodiment 3

[0061] A method for removing iopamidol in water by an ultraviolet / chlorine combined process, the concrete steps are as follows:

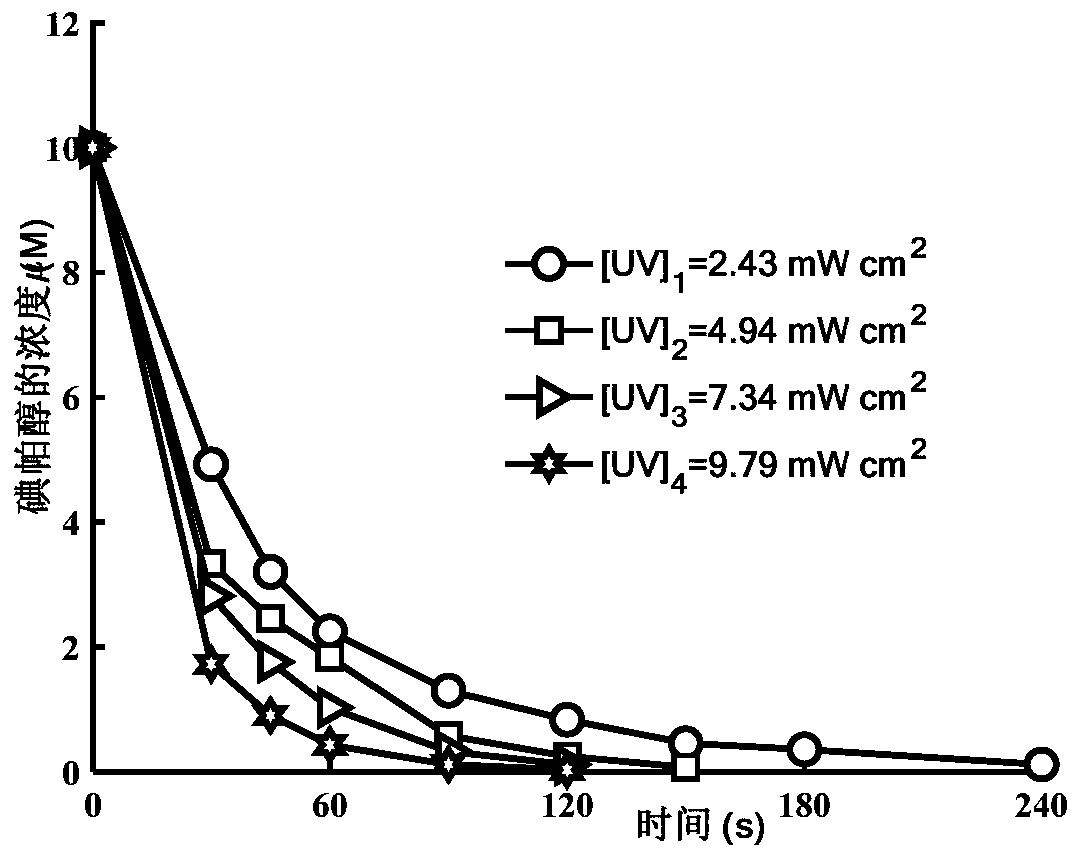

[0062] The initial concentration of iopamidol is 10 μM prepared with ultrapure water, the initial pH of iopamidol solution is adjusted to 7.0 with acid-base solution, and sodium hypochlorite is added to the iopamidol solution, and the dosage is [HOC1] 0 = 200 μM (in C1 2 meter), and UV irradiation was performed at the same time, and the UV intensity was controlled to be 2.43 mW / cm 2 , 4.94mW / cm 2 , 7.34mW / cm 2 , 9.76mW / cm 2 , under the experimental conditions where the reaction temperature was controlled at 25 °C, the removal rate of iopamidol was greater than 98% after the reaction for 300 s. image 3 .

[0063] Depend on image 3 It can be seen that with the increase of UV intensity, the photodegradation rate of iopamidol is gradually accelerated. UV intensity is 9.76mW / cm 2 , when the degradation time was only 120s, the degradation of iop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com