Small and portable sealed sucking-type numerical control cutting machine for gaskets

An adsorption and cutting machine technology, applied in metal processing and other directions, can solve the problems of reducing labor costs, low processing efficiency, and high labor costs, and achieve the effect of improving equipment flexibility, ensuring cutting accuracy, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

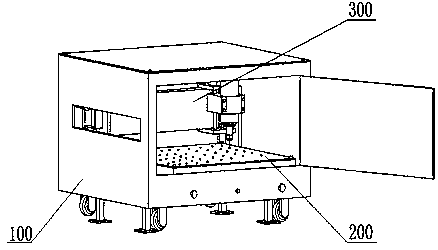

[0027] Such as figure 1 As shown, the small portable closed adsorption gasket CNC cutting machine includes a box module 100 , a material adsorption and fixing module 200 , and a cutting movement module 300 .

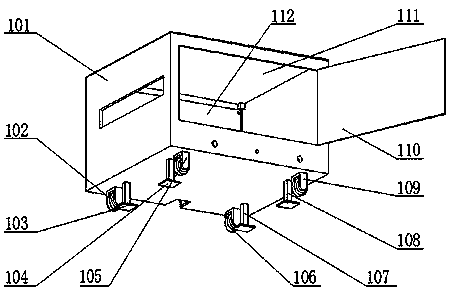

[0028] Such as figure 2The box module 100 shown is characterized in that: a traveling wheel installation hole is designed at the bottom of the whole box body 101, four installation holes are symmetrically distributed at the bottom of the whole box body 101, the first walking wheel 102, the second walking wheel 105, the The three 106 and the four 109 of the walking wheels are respectively installed on the bottom of the overall box 101 with screws. The bottom of the overall box 101 is designed with mounting holes for feet and fixing grooves for the feet. The four fixing grooves are symmetrically distributed at the bottom of the overall box 101. The center of the groove is designed with mounting holes for the legs. The first leg 103, the second leg 104, the third leg 107,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com