Maraging steel based on SLM (Selective Laser Melting) molded part and preparation method thereof

A technology of maraging steel and forming parts, applied in the field of steel materials, can solve the problems of poor performance of aging steel, small application range, unable to meet the needs of industrial design, etc., and achieve the effect of high strength and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing maraging steel based on SLM formed parts, comprising the following steps:

[0037] Step 1, using maraging steel powder as a raw material, adopting SLM molding to obtain an SLM molded part;

[0038]Step 2, carrying out surface treatment to the SLM molding in step 1;

[0039] Step 3, performing solution treatment, aging treatment or direct aging treatment on the surface-treated SLM formed part in step 2 to obtain the maraging steel of the selected area laser melting formed part.

Embodiment 1

[0041] A method for preparing maraging steel based on SLM formed parts, comprising the following steps:

[0042] Step 1, using maraging steel powder as a raw material, adopting SLM molding to obtain an SLM molded part;

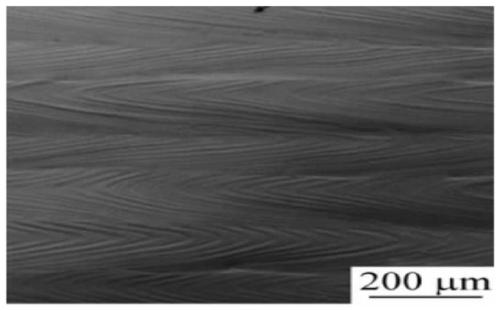

[0043] When using SLM molding technology to prepare SLM molded parts, add a sufficient amount of maraging steel powder into the powder tank before printing starts; because the commonly used 3D printers have the same size as the molding tank and the powder tank, adding martensite The amount of aging steel powder is not less than twice the height of the molded part; before printing, pass an inert protective gas into the printing chamber to ensure that the oxygen content in the printing chamber is lower than 0.05%, and then start printing; the entire printing process Among them, the flow rate of the inert protective gas is greater than 1.2Lpm; the specific printing parameters are: the laser scanning speed is 400-600mm / s, the laser power is 160-180W; the thickness...

Embodiment 2

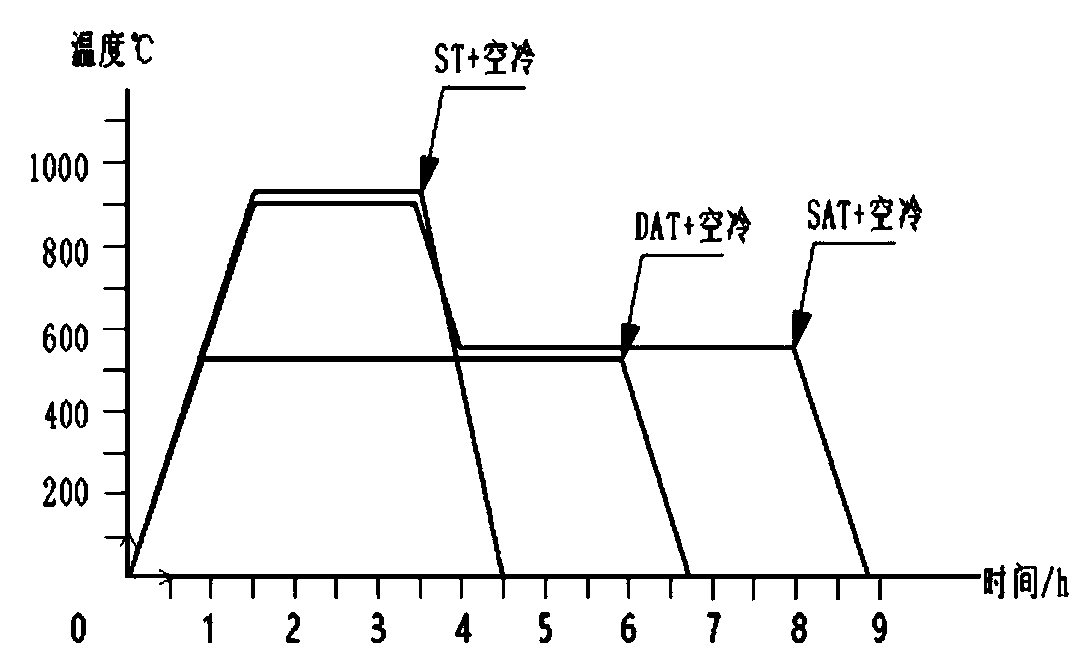

[0055] The preparation principle of embodiment 2 is basically the same as that of embodiment 1, except that in step 3 of embodiment 2, the aging treatment is carried out to the surface-treated SLM formed part to obtain the maraging steel of the SLM formed part; the aging treatment is specifically : In a vacuum environment or a protective gas atmosphere, the surface-treated SLM molded parts are heated to 900-920°C within 1h-2h; and kept at 900-920°C for 2-2.5h; then 10-15 ℃ / min to cool down to 540-560 ℃, and keep warm for 4-6h, then air-cooled to room temperature.

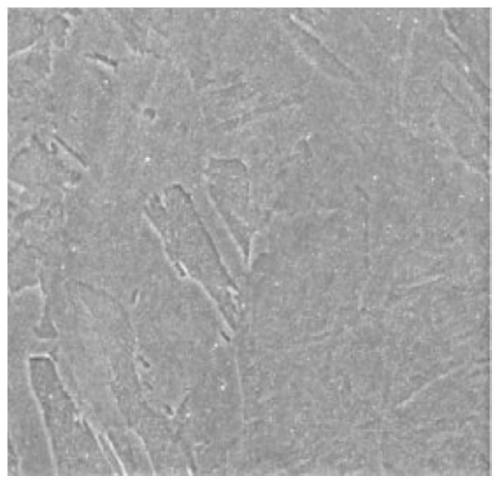

[0056] The microhardness of the maraging steel of the SLM formed part obtained in embodiment 2 is 670-712HV, and the tensile strength is 1022-1200Mpa; The maraging steel of SLM formed part has higher microhardness and tensile strength. Tensile strength, with better engineering application potential.

[0057] as attached figure 2 As shown, in Example 2, for aging treatment + final air cooling, when the aging treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com