Wearable steel ball segment broken material recycling device

A technology of scrap recovery and wear-resistant steel, which is applied in the direction of drying gas arrangement, filter screen, grille, etc., can solve the problems of falling scrap, incomplete recycling of scrap, low crushing rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

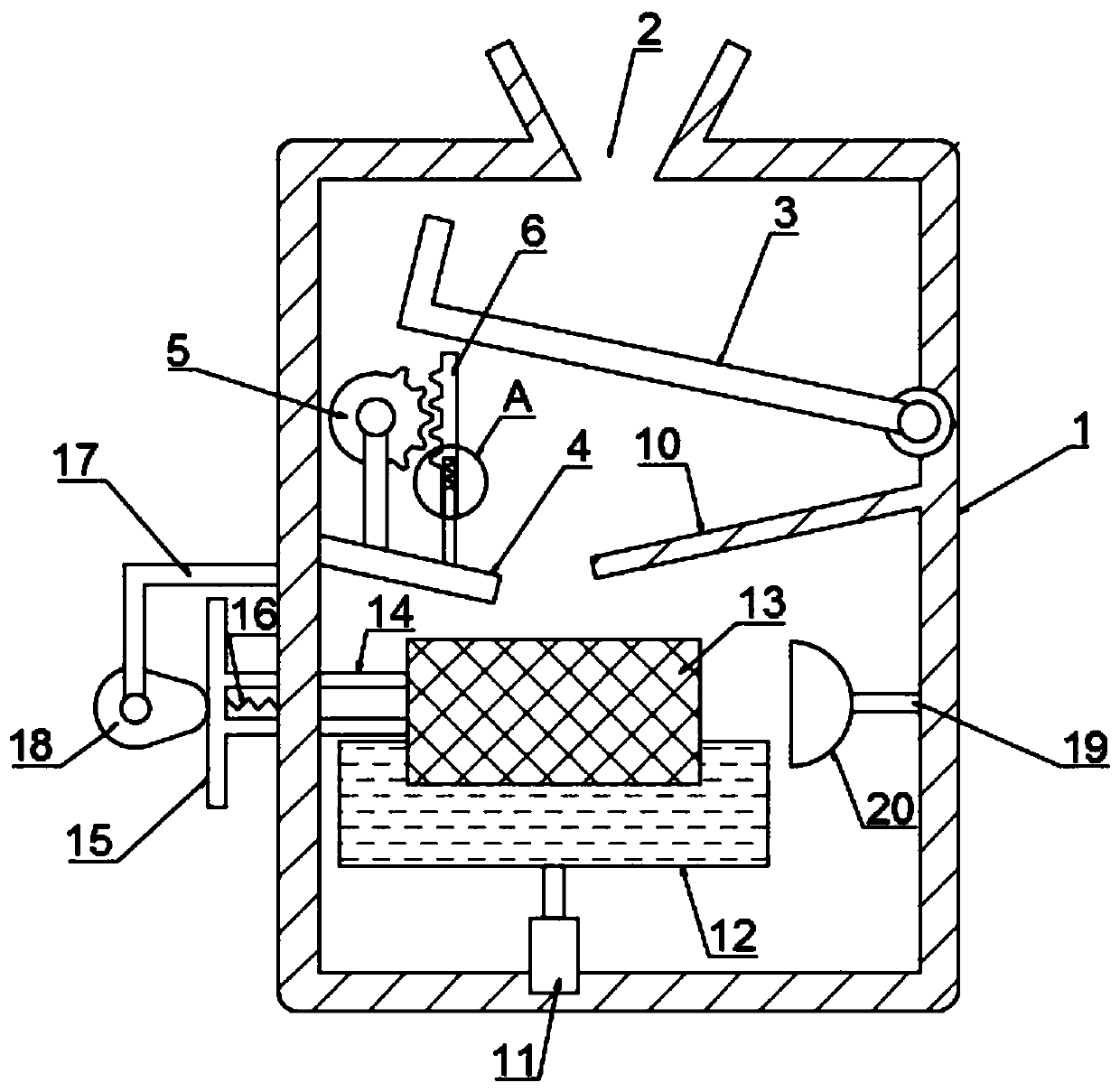

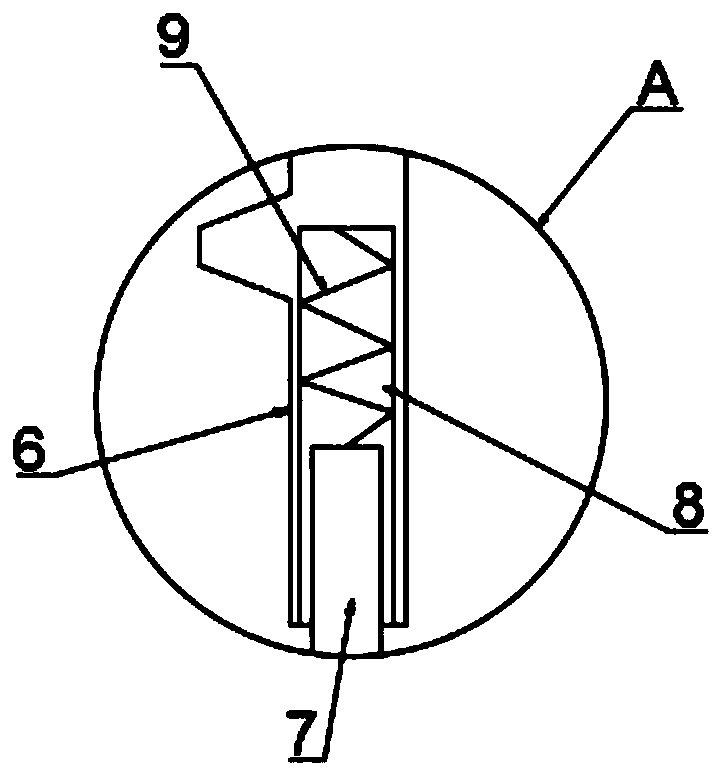

[0028] refer to Figure 2-4, a wear-resistant steel ball fragment recovery device, including a box body 1, the upper side wall of the box body 1 is provided with a feed port 2, and the four side inner walls of the feed port 2 are fixed with deflectors arranged obliquely , the inner wall of the box 1 is rotatably connected with a screen 3, an opening is provided on one side of the outer wall of the box 1, and a door panel 25 is installed on the opening, and the lower side wall of the opening corresponds to the upper side wall of the screen 3, the box Also be fixed with swash plate-4 on the inwall of 1, the upper end of swash plate-4 is fixed with fixed rod, the upper end of fixed rod is fixed with motor 1, and the driving end of motor 1 is fixed with incomplete gear 5, and the upper end of swash plate-4 The side wall is also fixed with a guide rod 7, the outer wall of the guide rod 7 is covered with a rack 6 positioned at one end of the screen 3, the lower end of the rack 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com