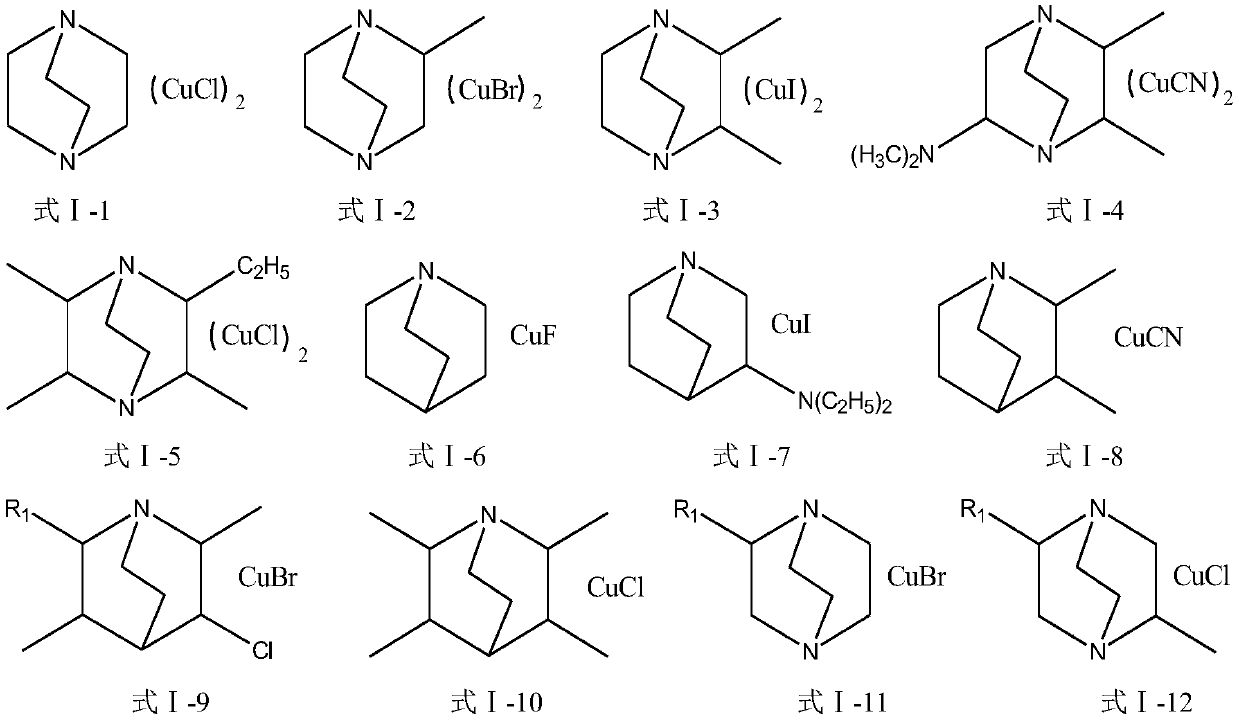

Azabicyclic complex catalyst, and preparation method and application thereof

A technology of azabicyclic and complexes, which is applied in the field of azabicyclic tertiary amine complex catalysts and its preparation, and can solve the problems of high catalyst price, low yield, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0076] The preparation of embodiment 1-6 azabicyclic tertiary amine complex catalyst

[0077] Embodiment 1-6 adopts the method of the present application to prepare the azabicyclic tertiary amine complex catalyst of the present invention, and the yield of the azabicyclic tertiary amine complex is more than 85%, and embodiment 1 and 3 have used The previous batch of mother liquor was used as the reaction solvent, and the yield reached more than 95%.

Embodiment 1

[0078] Embodiment 1: Adopt cuprous bromide and last batch of mother liquor to prepare formula Ⅰ-2 complex

[0079] (1) Pretreatment of cuprous bromide

[0080] The cuprous bromide purchased by industrial production or reagent companies contains a small amount of copper bromide, and the color is light green. In order to ensure the catalytic effect, pretreatment is required.

[0081] Add 450g of 3% dilute HBr into the four-neck flask, add 0.5gNa 2 SO 3 , remove the bromine or oxygen in the oxidation state in dilute HBr, and at the same time reduce the divalent copper ions to cuprous ions, quickly add 1000g of reagent-grade CuBr, replace it with high-purity nitrogen three times, stir at room temperature for about 2 hours, Since CuBr is insoluble in dilute HBr, and CuBr 2 Soluble in dilute HBr, to achieve the purpose of separation and purification, filter under nitrogen protection, rinse twice with absolute ethanol to remove moisture, and vacuum dry at 50-60°C for 2 hours to ...

Embodiment 2

[0086] Embodiment 2: Adopt cuprous bromide to prepare formula Ⅰ-2 complex

[0087] (1) the pretreatment method of cuprous bromide is the same as embodiment 1

[0088] (2) Preparation of formula Ⅰ-2

[0089] Measure 400mL of anhydrous acetonitrile, start stirring, then add 287.48g of cuprous bromide (99.7%) powder, under nitrogen protection, heat to 45-50°C to dissolve, and it becomes a light gray solution, which is set aside.

[0090] In the four-necked bottle, add 126.20g of 2-methyltriethylenediamine, add 200mL of acetonitrile, dissolve at room temperature, fill with nitrogen protection, and use a constant pressure feeding funnel to drop the cuprous bromide solution prepared above into , the temperature is 20-30°C, about 20 minutes after the addition, the light brown ligand compound is continuously precipitated, after the addition is completed, stir at room temperature for 1 hour, then cool down to -10°C, crystallize, and filter with nitrogen protection to avoid inhalatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com