Corrosion inhibitor with bactericidal and scale-inhibiting functions and preparation method thereof

A technology of corrosion inhibitors and bactericides, which is applied in the field of corrosion inhibitors with bactericidal and scale-inhibiting functions and its preparation, can solve the problems of no corrosion inhibitors, reduce labor costs and time, avoid the addition of additives, and the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

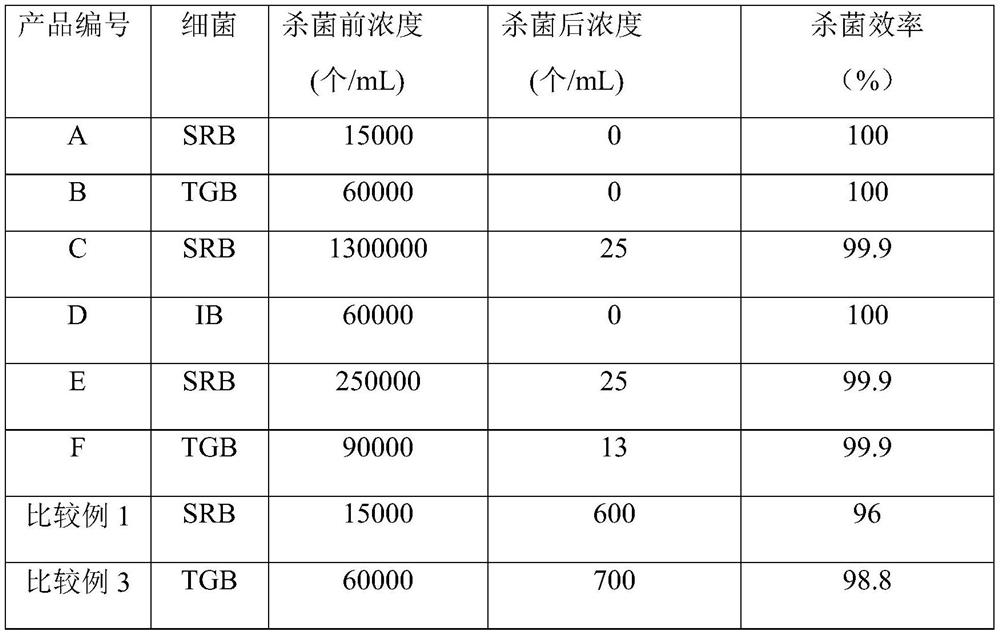

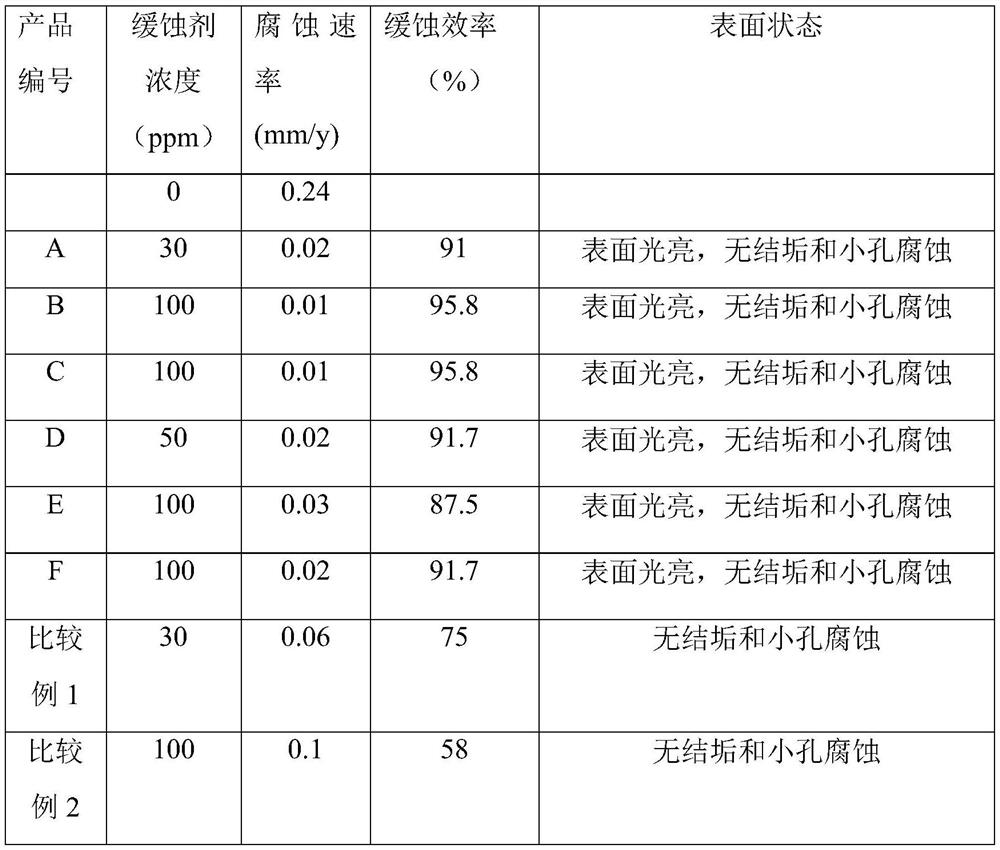

Examples

Embodiment 1

[0018] According to mass percentage, weigh 10 g of imidazoline quaternary ammonium salt, 12 g of dialkyl quaternary ammonium salt, 5 g of ethanol, 6 g of potassium hydroxyethylidene diphosphonate, 1.5 g of thiourea, and 65.5 g of water.

[0019] Add 40g of deionized water into the reactor, add 1.5g of thiourea, 10g of imidazoline quaternary ammonium salt, stir for 0.5 hours, add 12g of dialkyl quaternary ammonium salt, heat to 30°C, stir for 0.2 hours, add hydroxyethylidene di Add 6 g of potassium phosphonate, 5 g of ethanol, and 25.5 g of deionized water. After stirring for 0.1 hour, cool down to 20°C, continue stirring for 0.1 hour, and filter to obtain corrosion inhibitor product A with functions of sterilization, scale inhibition and corrosion inhibition.

Embodiment 2

[0021] According to mass percentage, weigh 24g of alkylpyridine quaternary ammonium salt, 14g of benzalkonium chloride, 16g of ethylene glycol, 10g of sodium gluconate, 2g of thiourea, 2.4g of potassium iodide, and 131.6g of water.

[0022] Add 90g of deionized water into the reactor, add 2g of thiourea, 2.4g of potassium iodide, 24g of alkylpyridine quaternary ammonium salt, stir for 1 hour, add 14g of benzalkonium chloride, heat to 45°C, stir for 0.5 hours, add gluconic acid Add 10g of sodium, 16g of ethylene glycol, and 41.6g of deionized water. After stirring for 1 hour, cool down to 30°C, continue stirring for 0.5 hours, and filter to obtain corrosion inhibitor product B with functions of sterilization, scale inhibition and corrosion inhibition.

Embodiment 3

[0024] According to mass percentage, weigh 15g of imidazoline, 16g of polyquaternium salt, 10g of butanol, 3g of polyaspartic acid, 2g of potassium hydroxyethylidene diphosphonate, 5g of glutaraldehyde, 1.5g of potassium iodide, and 47.5g of water.

[0025] Add 30g of deionized water into the reactor, add 1.5g of potassium iodide, 15g of imidazoline, stir for 0.8 hours, add 16g of polyquaternium salt, heat to 40°C, stir for 0.4 hours, add 3g of polyaspartic acid, hydroxyethylidene Potassium diphosphonate 2g, ethylene glycol 10g, and deionized water 17.5g, stirred for 0.7 hours, cooled to 25°C, added 5g of glutaraldehyde, continued to stir for 0.3 hours, filtered to obtain bactericidal, scale and corrosion inhibitors Functional corrosion inhibitor product C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com