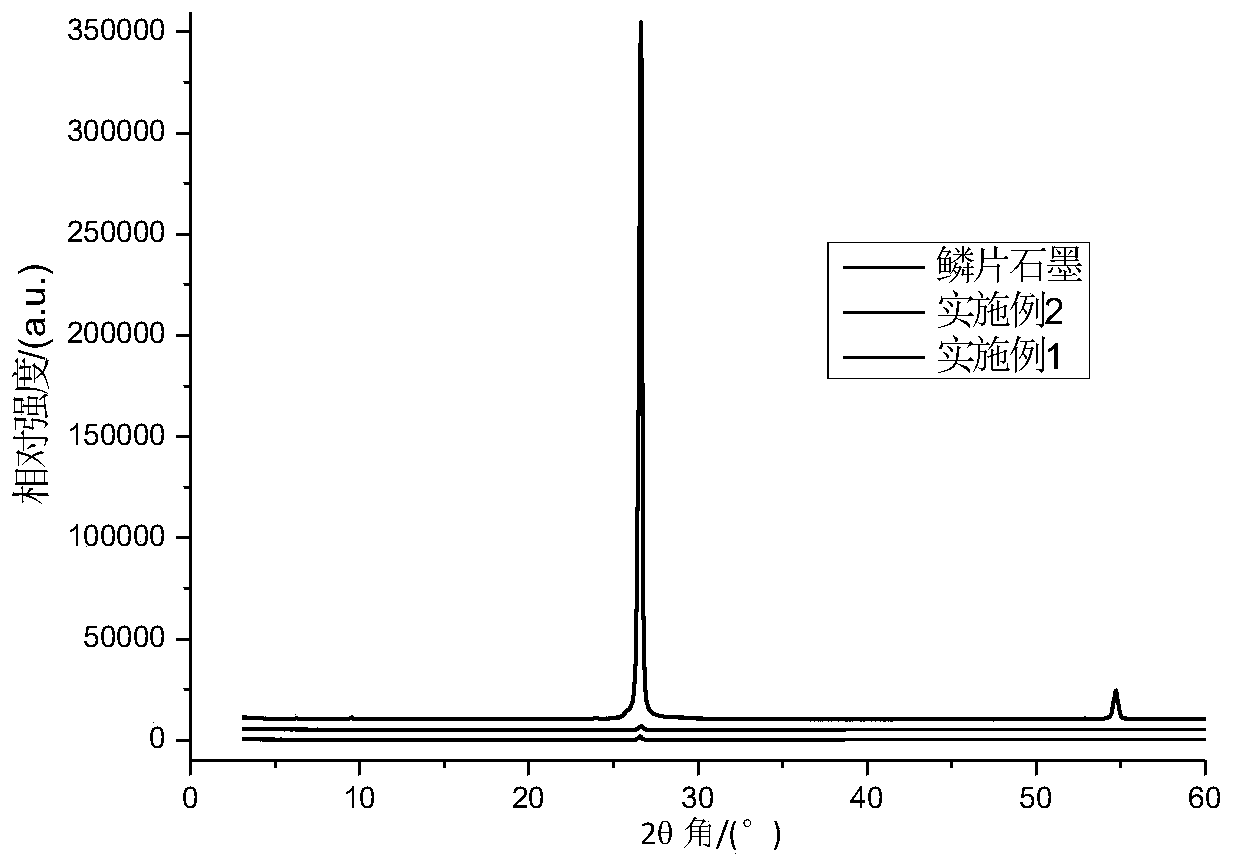

Method for preparing graphene by mechanically driving rubber molecules to strip flake graphite

A technology for exfoliating graphene and flake graphite, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as affecting the number of graphene layers, diameter, affecting graphene preparation cost and efficiency, etc. The production process and process conditions are controllable and the electrical conductivity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Beneficiation and enrichment of flake graphite

[0044] Put 50g of flake graphite ore powder with a diameter of less than 5.0mm into a ball mill jar, add water to make 1 liter of slurry, add 400g of zirconia ceramic balls with a diameter of 5mm, 7.5mL of engine oil, 2.5g of sodium hexametaphosphate, and the ball mill speed at 1500rpm, After grinding for 20 minutes, pour it into the flotation cell of the flotation machine for flotation, scrape off the upper layer of foam, dehydrate and dry to obtain high-purity flake graphite crystals.

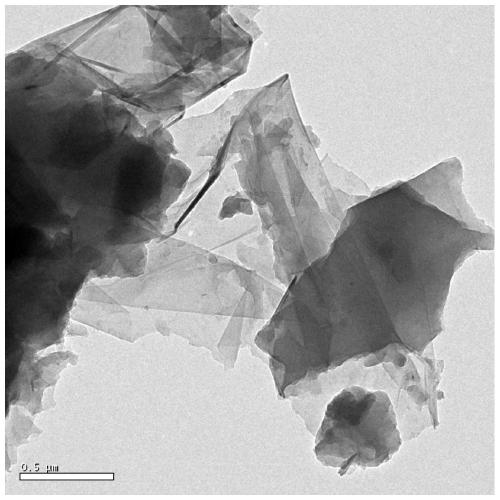

[0045] (2) Synergistic exfoliation of flake graphite crystals by styrene-butadiene rubber and nitrile rubber

[0046] Add 30g styrene-butadiene rubber and 70g nitrile-butadiene rubber into a 0.2L internal mixer, and add 10g of flake graphite crystals prepared in the above step (1), start the machine, and after banburying at a rotating speed of about 40rpm for 5min, take it out and turn it into a rotating speed The two-roll mill of a...

Embodiment 2

[0053] (1) Beneficiation and enrichment of flake graphite

[0054] Put 300g of flake graphite raw ore with a diameter of less than 0.05mm into a ball mill jar, add water to make 1 liter of slurry, add 300g of zirconia ceramic balls with a diameter of 5mm, 1.5mL of hydraulic oil and 1.5mL of rapeseed oil, 0.3g of sodium pyrophosphate, The speed of the ball mill is 300rpm. After grinding for 180min, it is poured into the flotation cell of the flotation machine for flotation, and the upper layer of foam is scraped off. After dehydration and drying, high-purity flake graphite crystals are obtained.

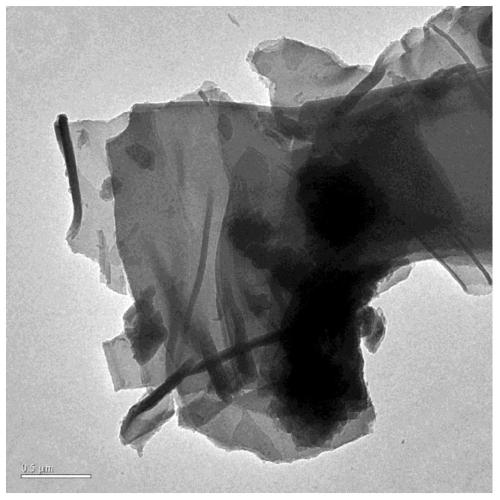

[0055] (2) EPDM exfoliated flake graphite crystal

[0056] Add 100g of EPDM rubber into a 0.2L internal mixer, and add 50g of flake graphite crystals prepared in the above step (1), start the machine, and after banburying for 20min at a speed of about 40rpm, take it out, and turn it into a double mixer with a speed of about 20rpm. The roller mill continued to mix, and added 10ml of g...

Embodiment 3

[0063] (1) Beneficiation and enrichment of flake graphite

[0064] Put 100g flake graphite raw ore with a diameter of less than 1.0mm into a ball mill, add water to make 1 liter of slurry, add 500g of zirconia ceramic balls with a diameter of 5mm, 0.8mL of gear oil, 0.2mL of soybean oil, 0.5g of polyethylene glycol and 0.5g sodium dodecyl sulfonate, ball mill speed 1000rpm, after grinding for 150min, pour it into the flotation cell of the flotation machine for flotation, scrape off the upper layer of foam, dehydrate and dry to obtain high-purity flake graphite crystals.

[0065] (2) Hydroxyl-terminated nitrile rubber exfoliated flake graphite crystal

[0066] Add 100g of hydroxy-terminated nitrile rubber into a 0.2L internal mixer, and add 15g of flake graphite crystal powder prepared in the above step (1) at the same time, start the machine at a speed of about 40rpm for banburying for 5min, take it out, and turn it into a speed of about 20rpm The two-roll mill continues mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com