Double-inner-water-cooling quadrupole oblique magnetic sine wave magnetizing head

A sine wave, magnetic head technology, applied in the direction of magnetic objects, transformer/inductor cooling, manufacturing stator/rotor body, etc., can solve the problems of unsatisfactory heat dissipation effect, poor cooling effect, affecting production efficiency, etc., to save manpower , the effect of reducing the temperature and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

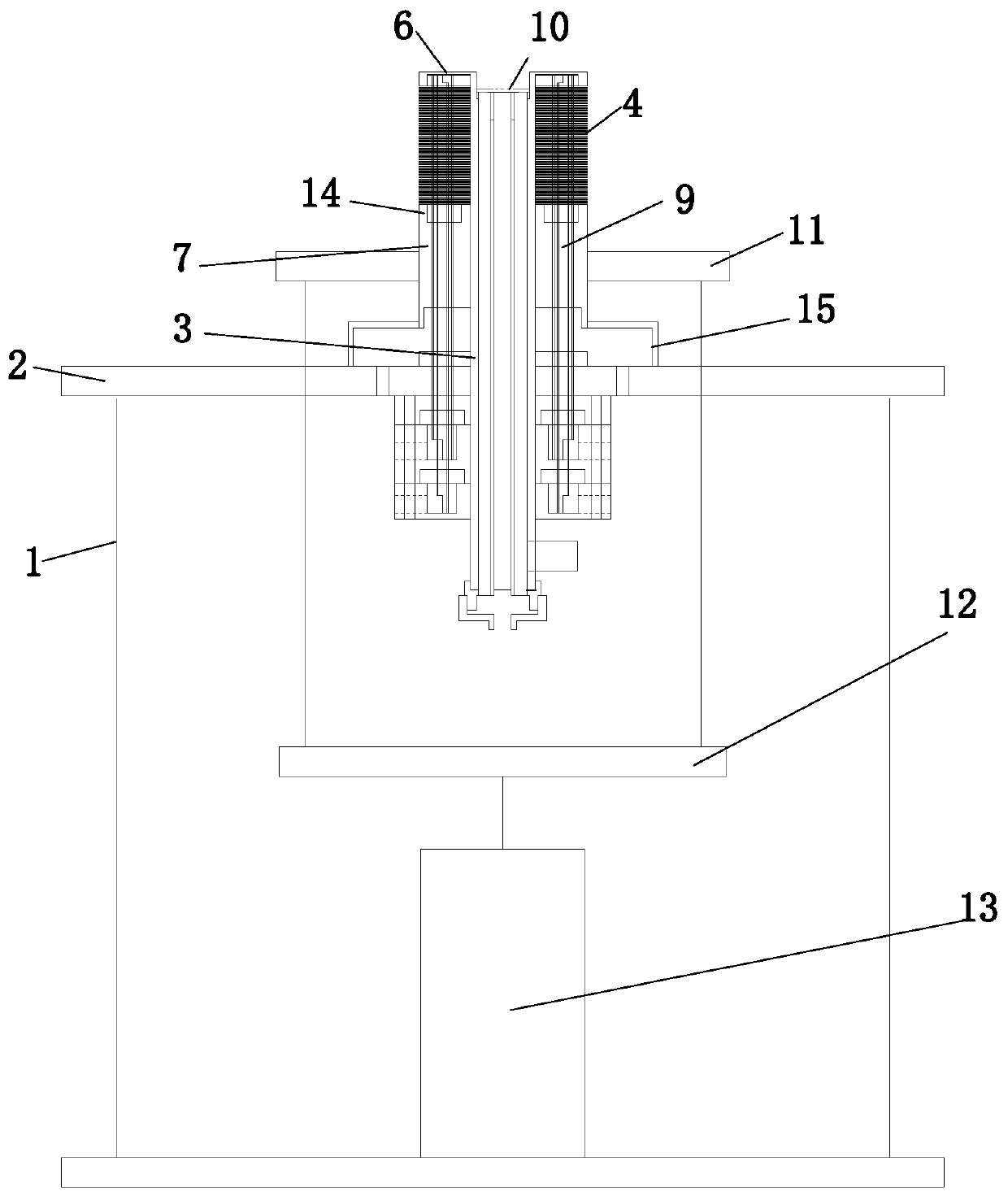

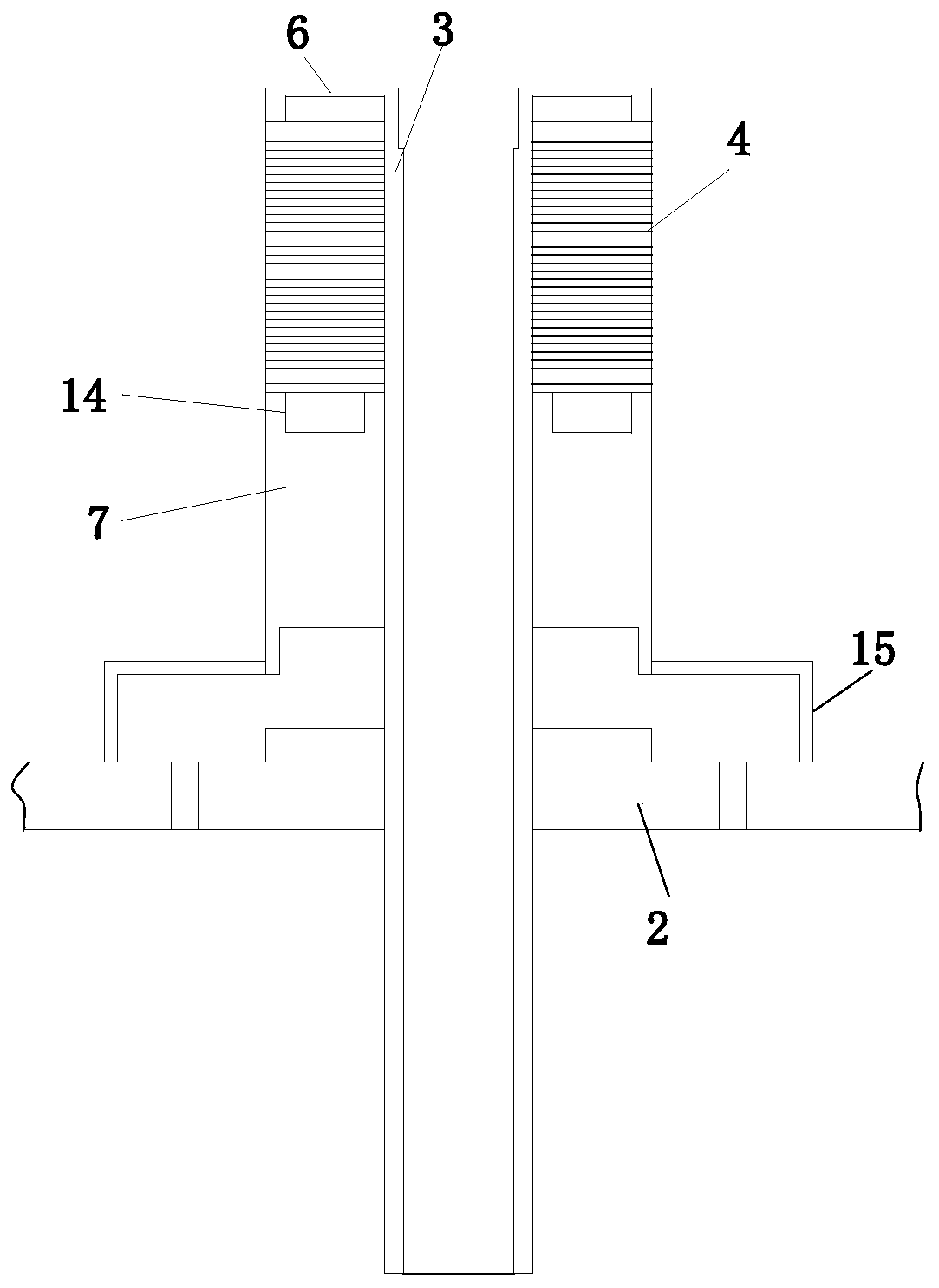

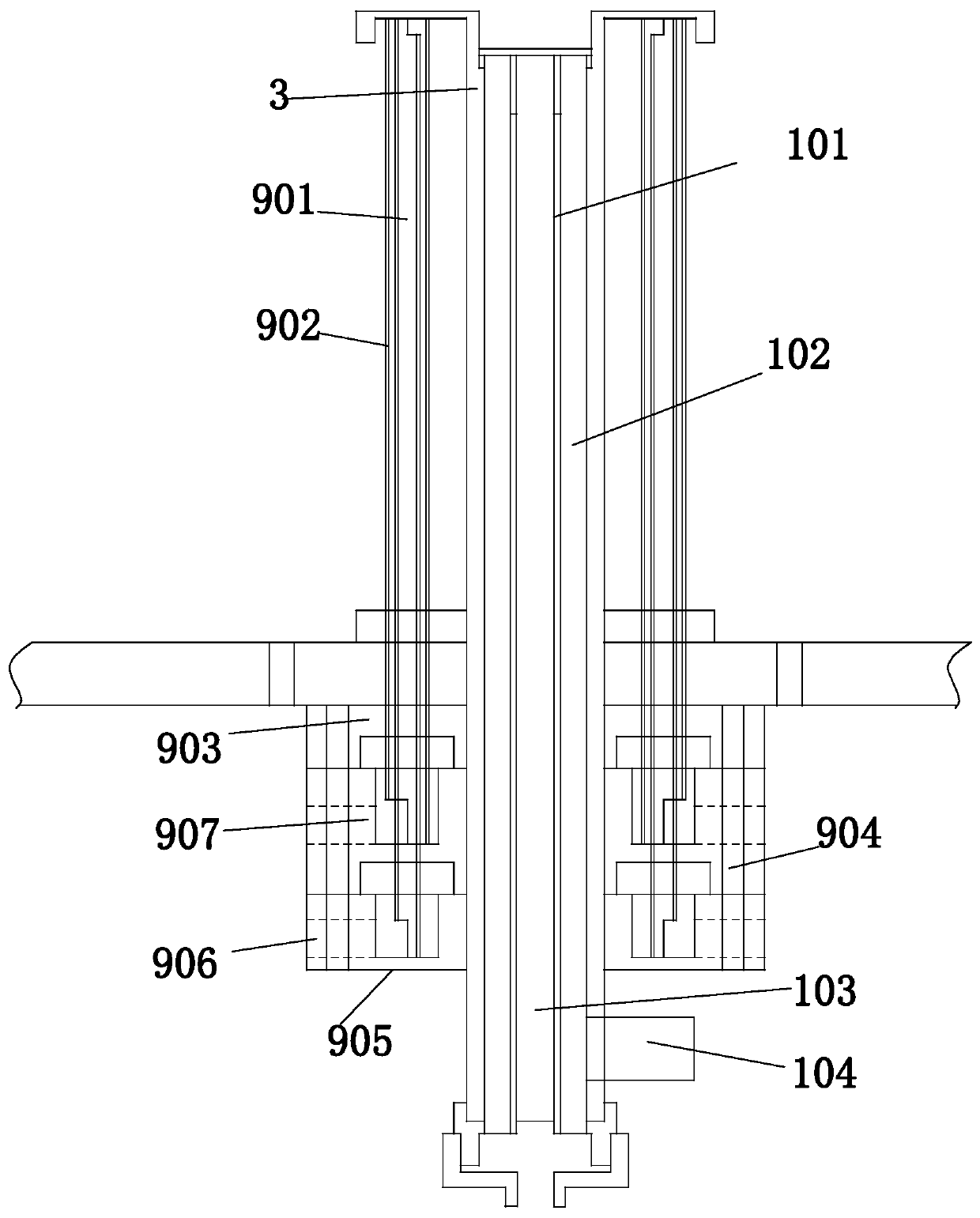

[0022] Example. A double internal water-cooled quadrupole oblique magnetic sine wave charging head, which is composed of figure 1 As shown in Figure 5, it includes a frame 1, a panel 2 is provided at the upper end of the frame 1, a central sleeve 3 is provided in the middle of the panel 2, and an iron core lamination group 4 is provided on the outer side of the upper part of the central sleeve 3, and the iron core laminations The winding group 5 is wound on the group 4, and the upper and lower ends of the core lamination group 4 are respectively provided with an upper buckle plate 6 and a lower plate 7; the iron core lamination group 4 is provided with a plurality of evenly distributed windings Slots 8, each winding slot 8 is provided with a winding cooling assembly 9, the inner side of the central...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com