Photo-thermal photovoltaic coupling energy-supply free-tracking solar condenser

A technology of solar concentrators and photothermal photovoltaics, applied in the directions of solar collectors, solar collector safety, solar collectors using working fluids, etc., can solve the problem of increasing the construction cost and output of solar concentrating utilization systems Problems such as poor energy stability and single output energy type have achieved the effect of zero-energy solar thermal photoelectric applications, high-efficiency coupling, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a photothermal photovoltaic coupling energy supply tracking-free solar concentrator, which can realize the joint energy supply of non-effective concentrating light power generation and concentrating light heating of the non-tracking concentrator; the solar concentrator can be used in Winter building solar heating system, greenhouse heating system, industrial heat supply system, etc.

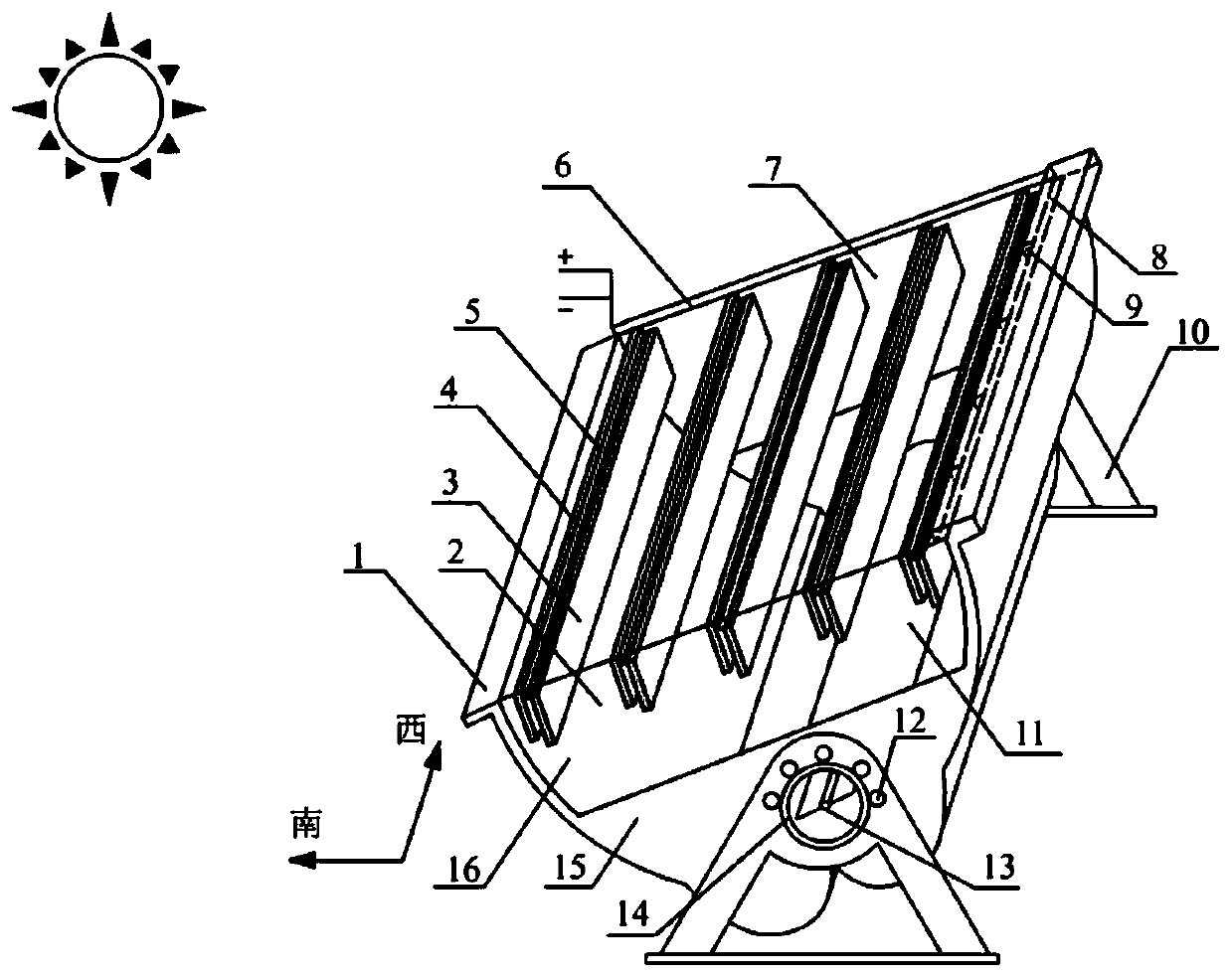

[0030] Such as figure 1 As shown, the tracking-free solar concentrator includes: a solar concentrator 2 , a glass vacuum tube 11 , a solar cell assembly, a glass cover plate 7 and a support 10 .

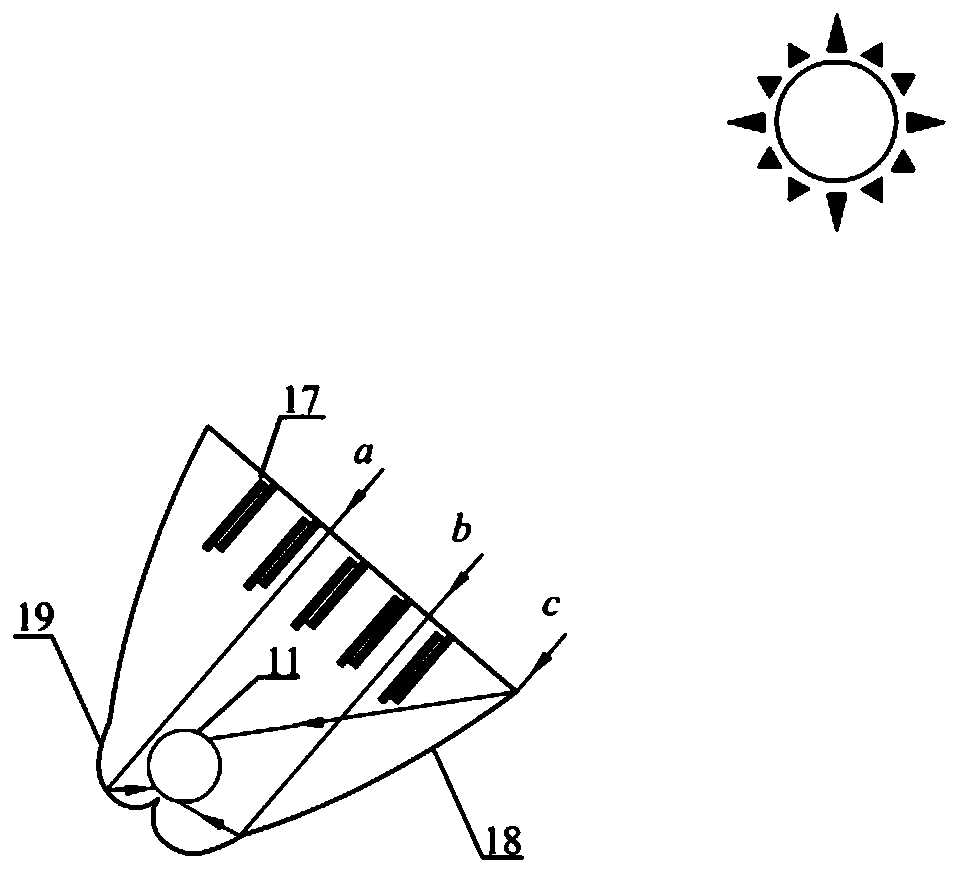

[0031] Wherein the solar concentrator 2 is a trough-type composite multi-curved solar concentrator, including two sections of semi-parabolic reflectors 18 with the same structure and two sections of involute reflectors 19 with the same structure; the parabolic reflector means that the reflector is a semi-parabola It is obtained after extending a certain length. The invol...

Embodiment 2

[0043] On the basis of the above-mentioned embodiment 1, in order to realize the automatic defrosting function, a hot air channel 17 and a micro-heat exchange channel 4) are further provided, specifically:

[0044] Each solar cell module is formed by back-to-back connection of solar cell panel A5 and solar cell panel B3; wherein solar cell panel A5 and solar cell panel B3 are arranged in a dislocation position, solar cell panel A5 is snapped into the card slot 20, and the solar cell panel There is a gap between B3 and the end face of the card slot 20 to form a hot air channel 17; the gap between the solar panel A5 and the back of the solar panel B3 forms a micro-heat exchange channel 4, which can realize natural convection heat exchange of the internal air.

[0045] At the same time, the solar concentrator 2 is provided with a hot air outlet 8 and a plurality of ventilation holes 9, and the hot air generated by the solar cell module passes through the hot air channel 17, and is...

Embodiment 3

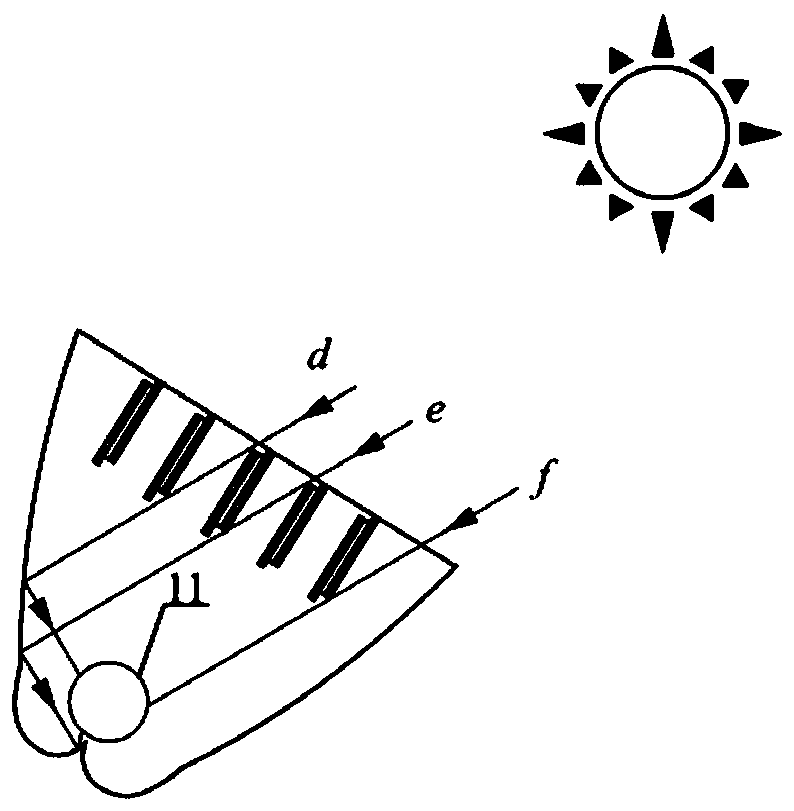

[0049] On the basis of the above-mentioned embodiment 1 or embodiment 2, in this embodiment, solar cell modules of different sizes are arranged inside the glass cover plate 7, such as Figure 6 As shown, a double-sided solar cell assembly with a larger area is arranged in the center of the inner surface of the glass cover plate 7 on the concentrator 2, and the area of the double-sided solar cell assembly is gradually reduced along the lateral direction of the concentrator 2, thereby improving The ability of the concentrator 2 to ablate frost, increase the proportion of the concentrator's external output electric energy, and reduce the amount of light that escapes from the concentrator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com