Aramid fiber surface ammoniation modifying method

A technology for aramid fiber and fiber surface, which is applied in fiber treatment, fiber type, textile and papermaking, etc. It can solve the problems of high requirements and short timeliness of fiber activation, achieve low equipment requirements, improve fiber surface energy and surface activity , the effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0030] A treatment method for ammonification modification of the surface of aramid fibers, comprising the steps of:

[0031] Step 1, cleaning and drying of the fiber surface; (1) Put the aramid fiber bundle into a Soxhlet extractor, add acetone and heat it, and clean the fiber by reflux for 24 hours;

[0032] (2) Take out the fibers treated in step (1), and dry them in an oven at 70-80°C for 2-4 hours.

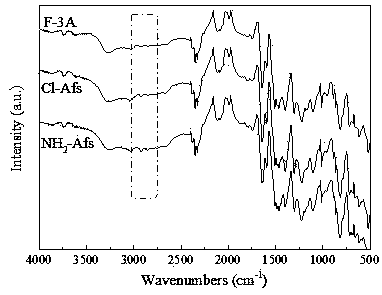

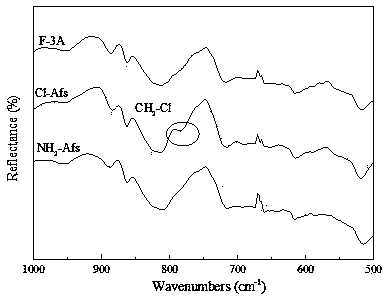

[0033] Step 2, the chlorination reaction on the surface of the fiber includes the following steps: (1) adding 1 to 5 g of anhydrous AlCl 3 Add 100ml of 1,4-dichlorobutane into a 250ml single-necked bottle, stir evenly with a magnetic stirrer, add 1-5g of dried F-3A fiber into the single-necked bottle, connect the condensing device, and react at 85°C for 4 ~8h;

[0034] (2) Take out the fibers treated in step (1), and wash them with acetone ...

PUM

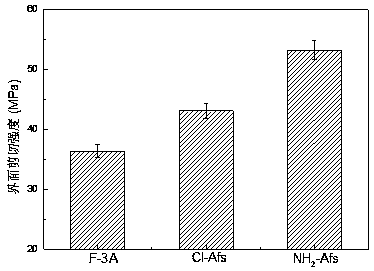

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com