Nano sol glass antifogging agent

A nano-sol and anti-fog technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of limited promotion and application, loss of anti-fog effect, uneven application, etc., to achieve clear vision and fast anti-fog effect Moreover, the effect of enhancing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

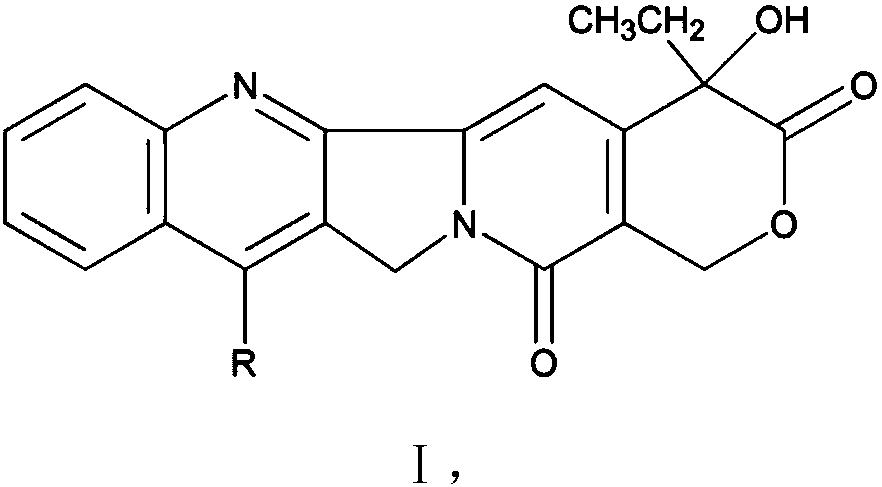

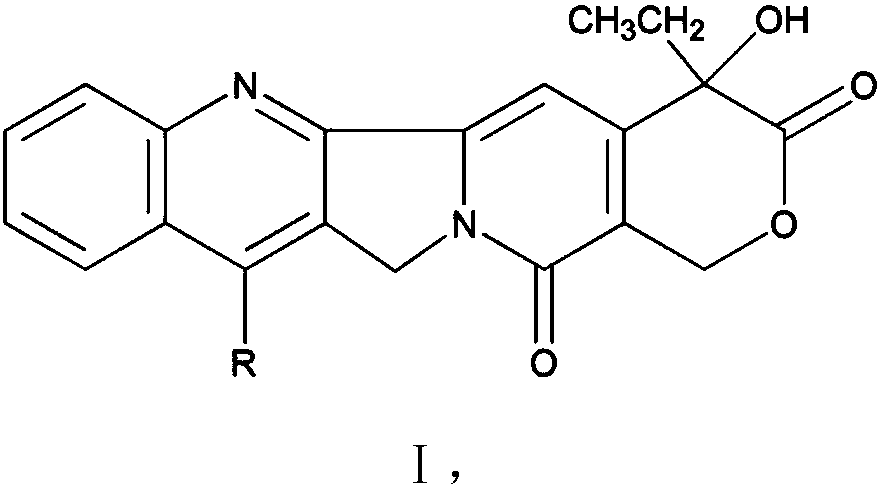

[0022] The composition of the nano sol glass antifogging agent is: 0.1wt% of silicon oxide compound sol; 0.01wt% of camptothecin compounds with the structure shown in formula I; and 99.89wt% of water.

[0023]

[0024]

[0025] Wherein, R is selected from any one of C1-C5 alkyl group, carboxyl group, ester group and amino group.

[0026] The anti-fog agent formulated in this example can extend the anti-fog time to 8 months, which fully meets the application requirements. When the solvent is ethanol, methanol, propanol, acetone, ethyl acetate, petroleum ether, the anti-fog time of about 8 months can still be obtained.

Embodiment 2

[0028] The composition of the nano sol glass antifogging agent is: 15wt% of titanium oxide compound sol; 2wt% of camptothecin compounds with the structure shown in formula I; and 83wt% of water.

[0029]

[0030] Wherein, R is selected from any one of C1-C5 alkyl group, carboxyl group, ester group and amino group.

[0031] The antifogging agent prepared by the method can extend the antifogging time to 8 months, fully meeting the application requirements. When the solvent is ethanol, methanol, propanol, acetone, ethyl acetate, petroleum ether, the anti-fog time of about 8 months can still be obtained.

Embodiment 3

[0033] The composition of the nano sol glass antifogging agent is: 30 wt% of aluminum oxide compound sol; 4 wt% of camptothecin compounds with the structure shown in formula I; and 66 wt% of water.

[0034]

[0035] Wherein, R is selected from any one of C1-C5 alkyl group, carboxyl group, ester group and amino group.

[0036] The antifogging agent prepared by the method can extend the antifogging time to 8 months, fully meeting the application requirements. When the solvent is ethanol, methanol, propanol, acetone, ethyl acetate, petroleum ether, the anti-fog time of about 8 months can still be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com