Impregnation-free sliding plate brick and preparation method thereof

A sliding brick and sintered corundum technology, which is applied in the field of impregnation-free sliding brick and its preparation, can solve environmental pollution and human health problems, achieve good erosion resistance and erosion resistance, reduce procedures, and speed up delivery time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

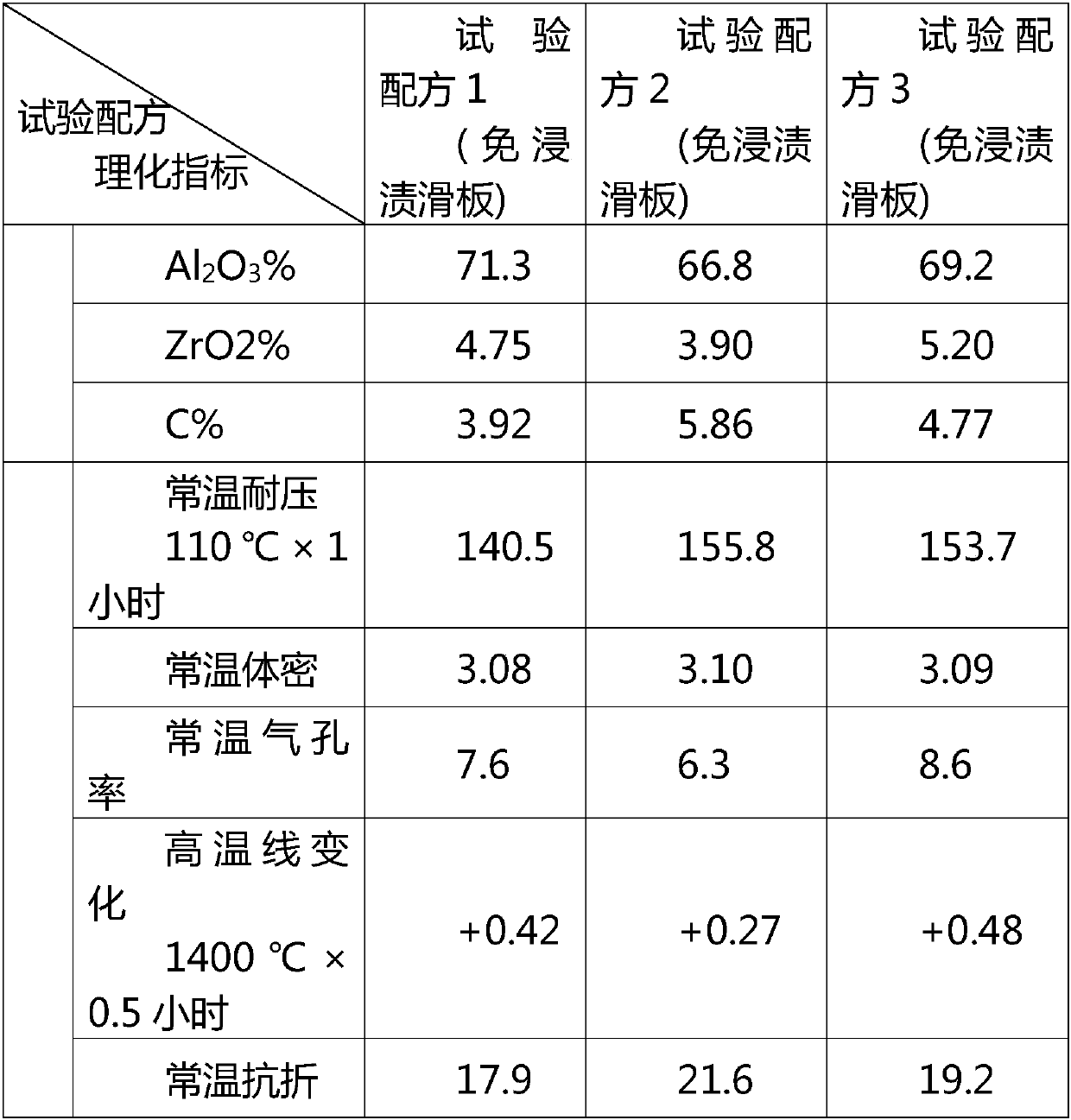

Examples

preparation example Construction

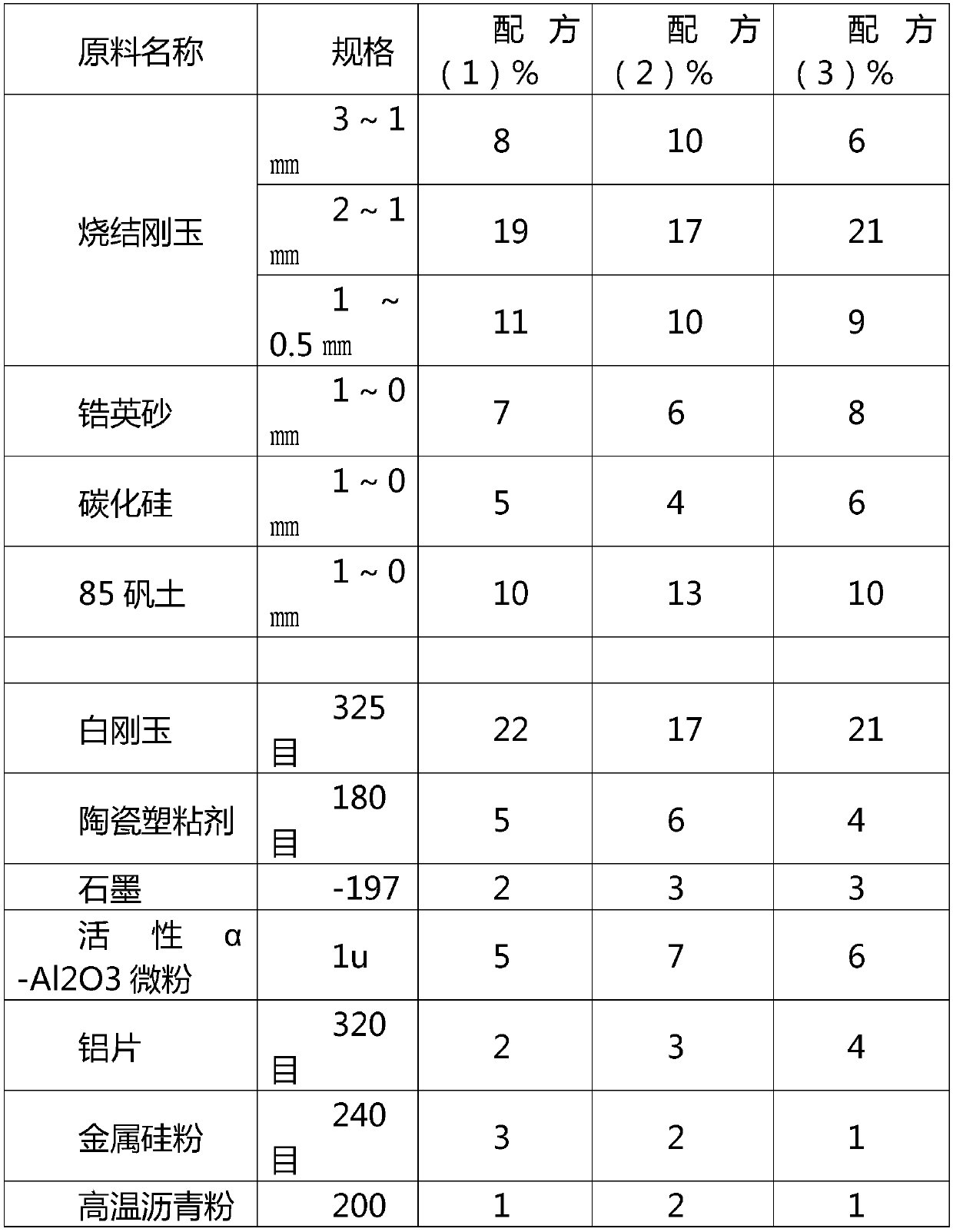

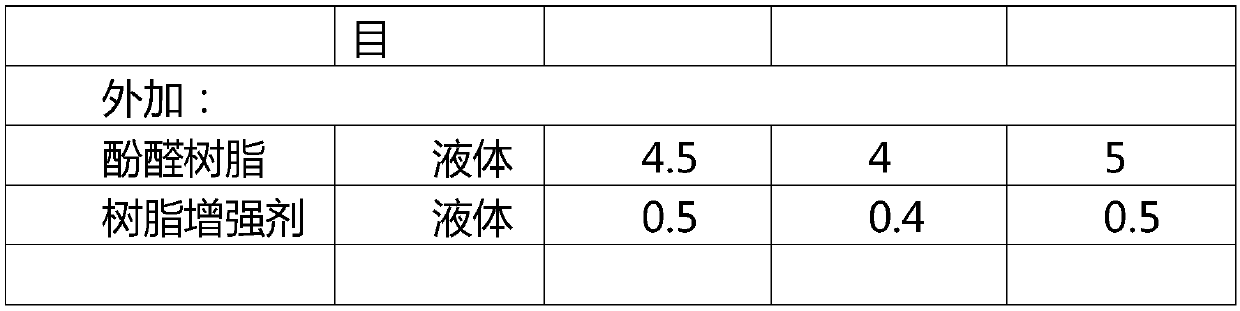

[0031] The preparation method of impregnation-free sliding bricks comprises sintered corundum, zircon sand, silicon carbide, 85 bauxite, white corundum, ceramic plastic adhesive, active α-Al2O3 micropowder, graphite-197, aluminum flakes, metal silicon powder, Stir and mix high-temperature asphalt powder, phenolic resin, and resin reinforcing agent, then shape it and dry it naturally, then put it into a drying kiln and slowly heat it up for 40-60 hours. The tunnel kiln is evenly heated to 580°C ± 20°C, kept for 15-20 hours, and finally cooled at a constant speed for 16-25 hours.

[0032] Impregnation-free sliding brick and its preparation method, the drying kiln temperature is evenly raised to 80°C within 1 hour, and kept at 80°C for 12 hours, and then the temperature is evenly raised from 80°C to 190°C within 24 hours, and at 190°C Keep warm for 20 hours.

[0033] In the non-dipping sliding brick and its preparation method, the temperature is evenly raised to 580°C±20°C withi...

Embodiment 1

[0038] Raw material specifications are as follows:

[0039] Sintered corundum: Al 2 o 3 Content ≥ 95%, Fe2O3 content ≤ 1.8%, SiO2 content < 1.2%,

[0040] Zircon sand: ZrO2 content ≥ 65%, Fe2O3 content ≤ 0.2%, SiO2 content ≤ 33%,

[0041] Silicon carbide: SiC content ≥ 97%, Fe2O3 content ≤ 0.55%, F.C content ≤ 0.55%

[0042] 85 bauxite: Al 2 o 3 Content ≥ 85%, Fe2O3 content < 1%, TiO2 content < 4.0%;

[0043] White corundum: Al 2 o 3 Content ≥ 99%, Fe2O3 content ≤ 0.2%;

[0044] Ceramic plastic adhesive: MgO content ≥ 45%, SiO2 content ≥ 40%; Fe2O3 content ≤ 10%;

[0045] Graphite: C content ≥ 97%

[0046] Active α-Al2O3 powder: Al 2 o 3 Content ≥ 72%, Fe2O3 ≤ content 0.3%;

[0047] Aluminum sheet: active aluminum Al≥97%;

[0048] Metal silicon powder: Si content ≥ 97%, Fe2O3 content ≤ 1.0%;

[0049] High-temperature asphalt powder: softening point 95-120°C, ash content 0.1-0.5%, volatile content 55-75%;

[0050] Phenolic resin: carbon residue 45±4%, solid cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com