Process for preparing tellurium dioxide

A tellurium dioxide and process technology, which is applied in the field of producing tellurium dioxide, can solve the problems of low leaching rate, low recovery rate, and large investment in equipment costs, and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

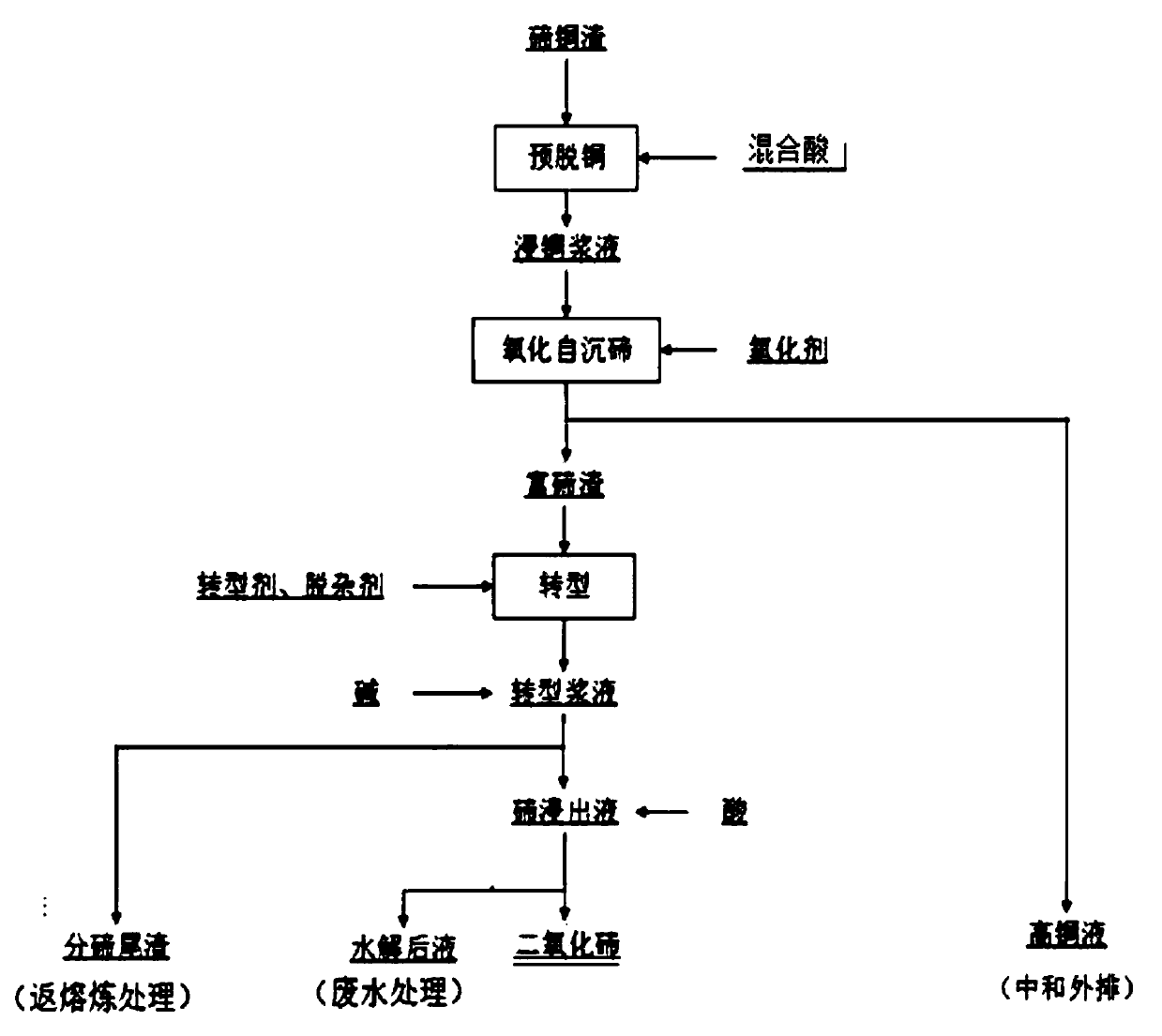

Method used

Image

Examples

Embodiment 1

[0035] Take 200kg tellurium copper slag, add water according to the liquid-solid ratio of 6:1, add 65kg of 93% sulfuric acid, add 50kg of hydrochloric acid, stir and react for 15min, feed chlorine gas at 50L / min until the final pH is controlled to 3, the reaction temperature is 75°C, and the reaction Time 2h, get high tellurium slag 120kg;

[0036]The high tellurium slag was mixed with water according to the liquid-solid ratio of 6:1, the temperature was raised to 75°C, sulfur dioxide was introduced at 30L / min for 0.5h, the pH was controlled by hydrochloric acid to 1, and then 75kg of caustic soda was added, and the reaction time was 2h to obtain the fraction Tellurium tailings 23kg, tellurium leaching solution 843L;

[0037] The temperature of the tellurium leaching solution was raised to 70°C, and 1:1 diluted 93% sulfuric acid was slowly added to control the pH to 5-6, and 87kg of tellurium dioxide was obtained by filtration.

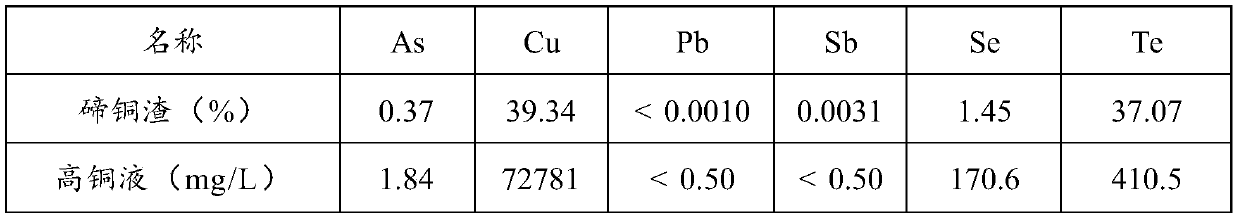

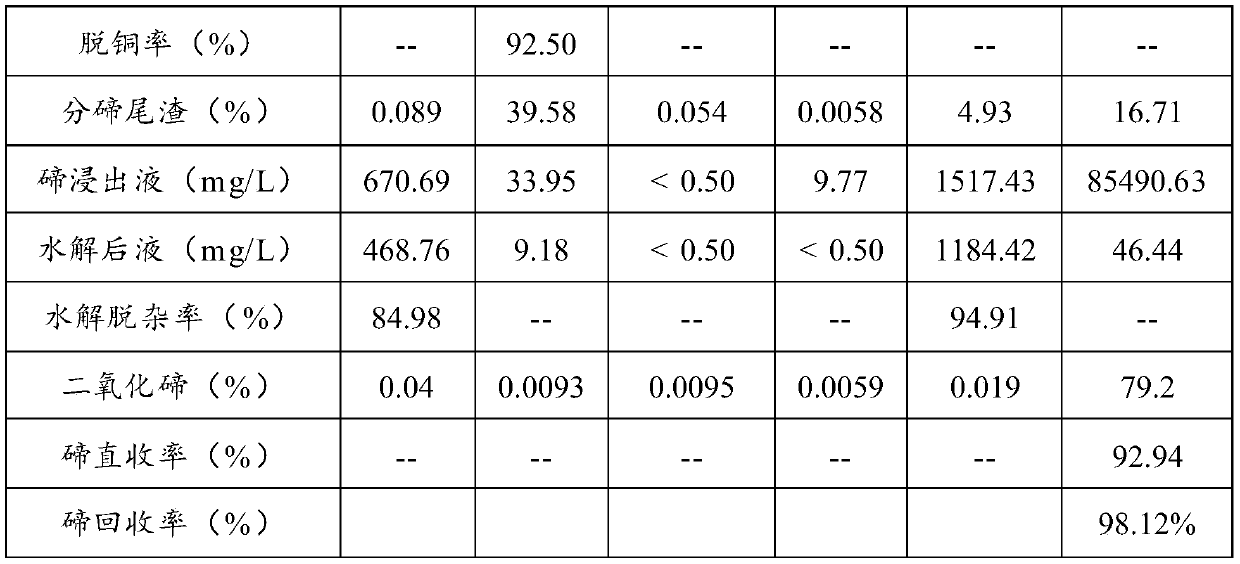

[0038] The data of the raw materials and produ...

Embodiment 2

[0044] Take 200kg tellurium-copper slag, add water according to the liquid-solid ratio of 5:1, add 75kg of 93% sulfuric acid, add 44kg of hydrochloric acid, stir and react for 15min, feed chlorine gas at 50L / min to finally control pH = 3, and react at a temperature of 75°C. Time 2h, obtain high tellurium slag 103kg;

[0045] Mix the high tellurium slag according to the liquid-solid ratio of 6:1, raise the temperature to 75°C, feed sulfur dioxide 30L / min for 0.5h, control the pH=1 by hydrochloric acid, add 65kg of caustic soda, and react for 2h to obtain the tellurium tail 15kg of slag, 742L of tellurium leaching solution;

[0046] Raise the temperature of the tellurium leaching solution to 70°C, slowly add 1:1 diluted 93% sulfuric acid to control the pH to 5-6, and filter to obtain 68kg of tellurium dioxide.

[0047] The data of the raw materials and products involved in the above-mentioned preparation process are shown in the following table:

[0048] Table 2 Example 2 prep...

Embodiment 3

[0053] Take 200kg tellurium copper slag, add water according to the liquid-solid ratio of 6:1, add 67kg of 93% sulfuric acid, add 40kg of hydrochloric acid, stir and react for 15min, feed chlorine gas at 50L / min until the final pH is controlled to 3, the reaction temperature is 75°C, and the reaction Time 2h, obtain high tellurium slag 132kg;

[0054] Mix the high tellurium slag according to the liquid-solid ratio of 6:1, raise the temperature to 75°C, feed sulfur dioxide 30L / min for 0.5h, control the pH=2 with hydrochloric acid, add 75kg of caustic soda, and react for 2h to obtain the tellurium tail 27kg of slag, 870L of tellurium leaching solution;

[0055] The temperature of the tellurium leaching solution was raised to 70°C, and 93% sulfuric acid diluted 1:1 was slowly added to control the pH between 5 and 6, and 69kg of tellurium dioxide was obtained by filtration.

[0056] The data of the raw materials and products involved in the above-mentioned preparation process are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com