Self-fastening type lubricating bearing plate

A technology for lubricating bearings and plates, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as lowering yield, heat dissipation problems, and affecting lubrication performance, so as to improve wear resistance and use Longevity is beneficial and the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

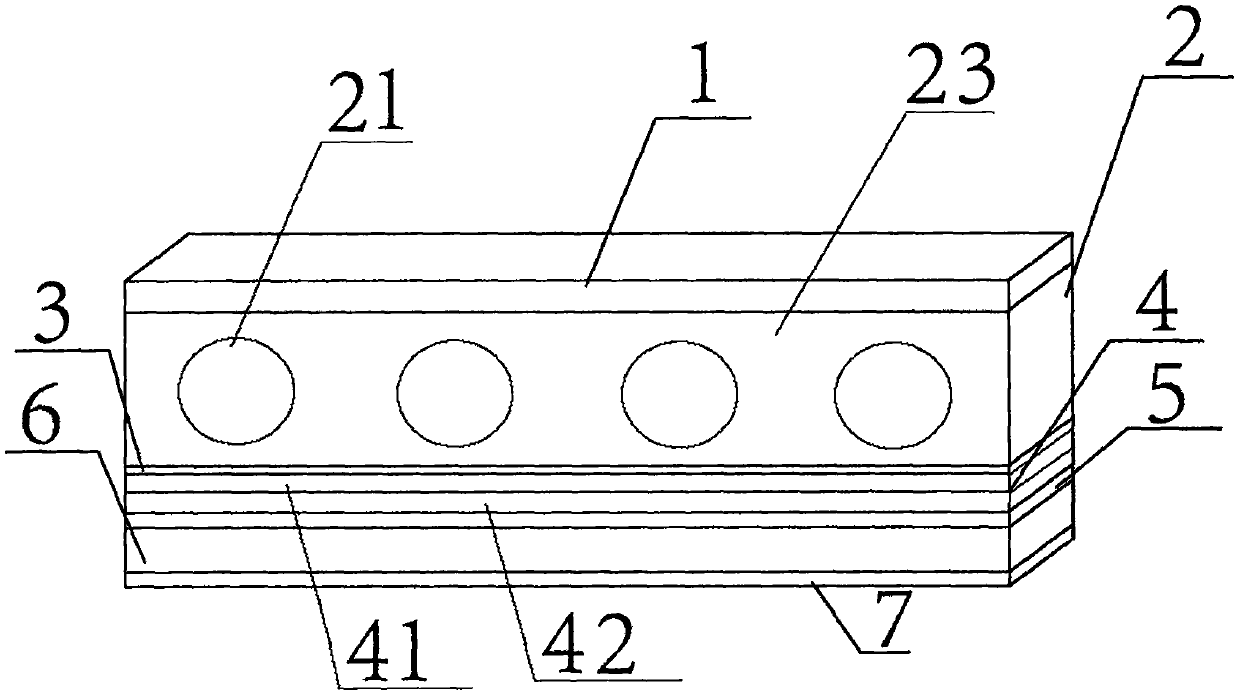

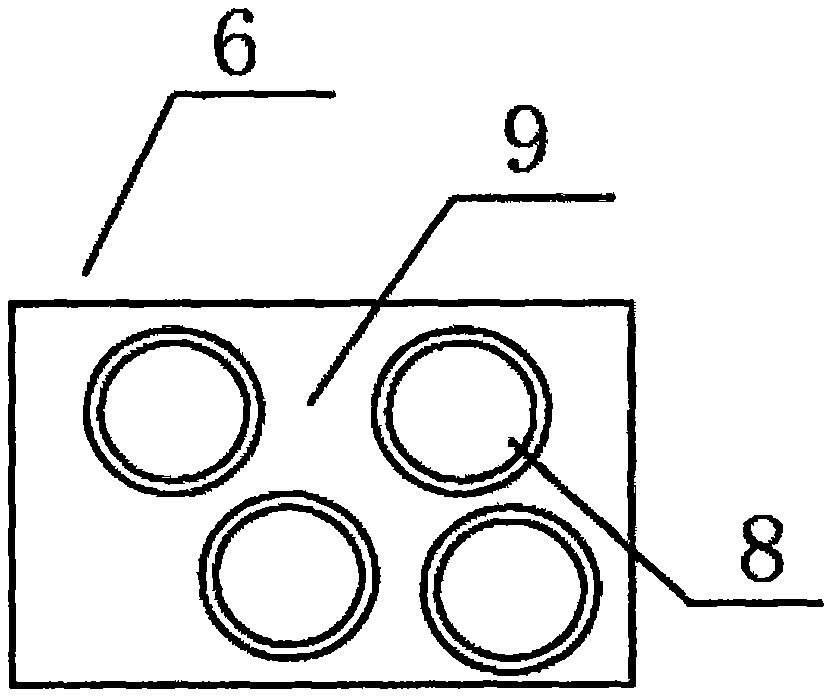

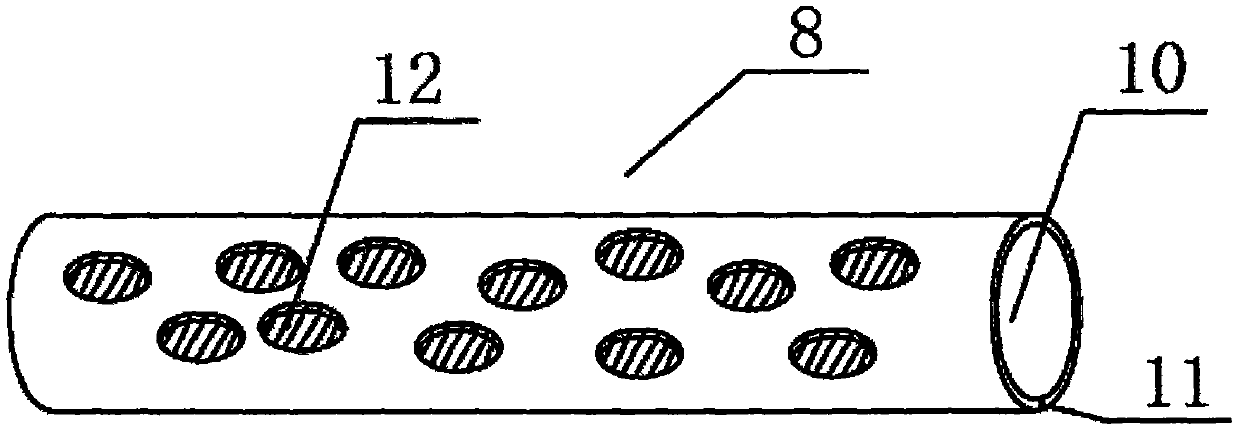

[0020] See attached Figure 1-4 , the self-fastening lubricating bearing plate includes a lubricating copper powder layer 1, a steel plate layer 2, an epoxy structural adhesive layer 3, a fluorine-containing polyimide film layer 4, a thermally conductive adhesive layer 5, a heat dissipation layer 6, and a zinc oxide layer 7; The heat dissipation layer includes porous fiber 8 and airgel 9; the porous fiber is located in the airgel; the porous fiber includes a porous fiber 10 and a porous fiber adhesive layer 11; the porous fiber adhesive layer is located on the outer surface of the porous fiber; the porous fiber adhesive layer There is a graphene layer structure 12 in the hole; a lubricating copper powder layer, a steel plate layer, an epoxy structural adhesive layer, a fluorine-containing polyimide film layer, a thermally conductive adhesive layer, a heat dissipation layer, and a zinc oxide layer are arranged in sequence, among which polyamide One side 41 of the imide film (12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com