Forming method and product of multilevel microstructure on metal surface

A metal surface and microstructure technology, which is applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of poor repeatability, low preparation efficiency, easy to be damaged, etc. The process is simple and avoids the effect of easy destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1: Roughly polish the surface of 7075 aluminum alloy with a polishing machine to increase the adhesion between the powder and the surface, and clean it in ultrasonic for five minutes, then take it out, and dry the excess water on the surface with an air gun;

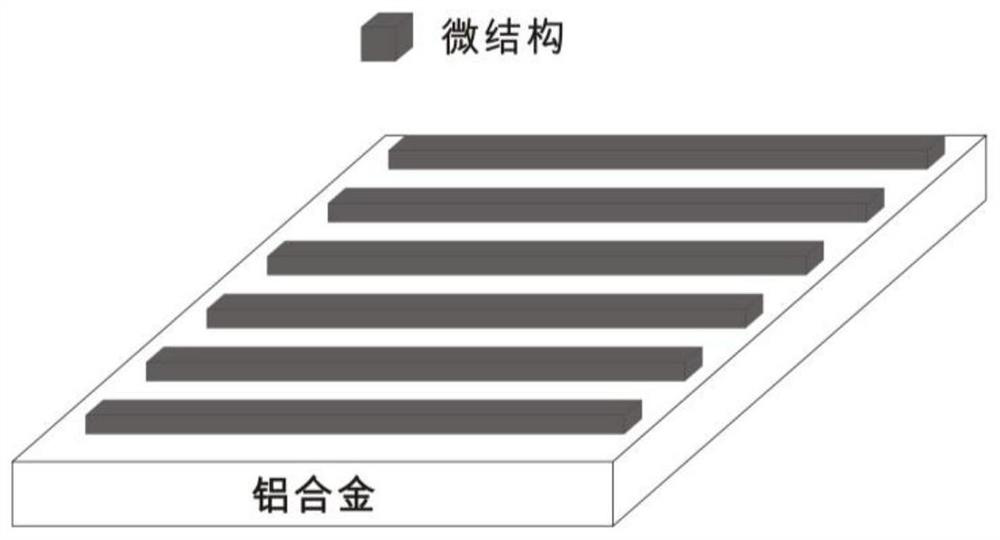

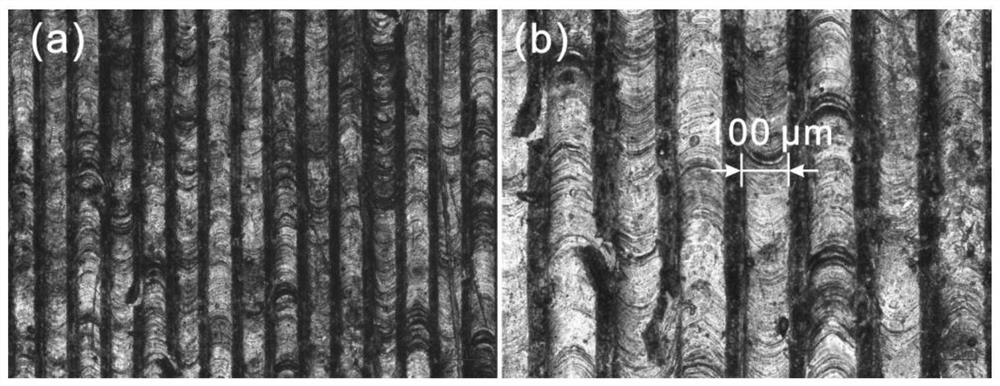

[0045] Step 2: If figure 1 As shown, it is planned to prepare array horizontal stripe microstructure, plan in the computer through the path planning software, set the laser scanning path as parallel strip scanning, the scanning distance is 150 μm, the layer thickness is 50 μm, and the number of printing layers is 1 layer ;

[0046] Step 3: Fix the 7075 aluminum alloy on the abutment in the forming cavity of the dual laser SLM equipment, and level the surface of the aluminum alloy at the Z-axis 0 point, so that the substrate serves as the forming plane;

[0047] Step 4: Fill 7075 aluminum alloy spherical powder around the aluminum alloy, and the particle size of the powder is between 15 μm and 60 μm;

[0048...

Embodiment 2

[0052] Step 1: Roughly polish the surface of 7075 aluminum alloy with a polishing machine to increase the adhesion between the powder and the surface, and clean it in ultrasonic for five minutes, then take it out, and dry the excess water on the surface with an air gun;

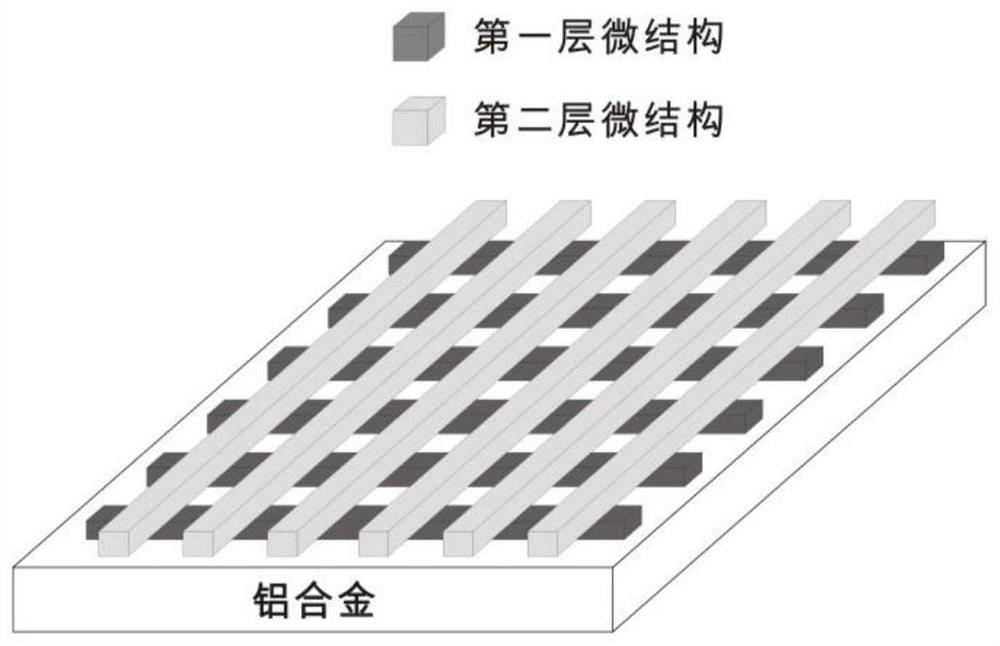

[0053] Step 2: If image 3 as shown, image 3 The middle part is to prepare the array hierarchical grid microstructure, which is planned in the computer through the path planning software. For the array hierarchical grid microstructure, the laser scanning path is set as parallel strip scanning, the scanning distance is 150 μm, and the layer thickness is 30 μm. , the number of printing layers is 2 layers, and the rotation angle between layers is 90°;

[0054] Step 3: Fix the 7075 aluminum alloy on the abutment in the forming cavity of the double laser SLM equipment, and use the surface of the aluminum alloy as the Z-axis 0 point for leveling;

[0055] Step 4: Fill 7075 aluminum alloy spherical powder around ...

Embodiment 3

[0060] Step 1: Roughly polish the surface of the stainless steel with a polishing machine to increase the adhesion between the powder and the surface, and clean it in ultrasonic for five minutes, then take it out, and dry the excess water on the surface with an air gun;

[0061] Step 2: To prepare the array hierarchical grid microstructure, plan in the computer through the path planning software, set the laser scanning path as parallel strip scanning, the scanning distance is 100 μm, the layer thickness is 80 μm, and the number of printing layers is 2 layers , the rotation angle between layers is 120°;

[0062] Step 3: Fix the stainless steel on the abutment in the forming cavity of the double laser SLM equipment, and use the stainless steel surface as the Z-axis 0 point for leveling;

[0063] Step 4: Fill Ti6Al4V powder around the stainless steel, the powder particle size is 15μm~60μm;

[0064] Step 5: Pour the above-mentioned Ti6Al4V powder into the powder cylinder of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com