Steam-generating freeze-dried mask

A technology of freeze-drying and facial mask, applied in cosmetics, bathing devices, cosmetic preparations, etc., can solve problems such as aging, allergies, and dry skin, and achieve the effect of avoiding dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of steam freeze-dried facial mask, comprises heating mask, and the surface of described heating mask is covered with one deck freeze-dried membrane cloth, contains the composition of following mass percentage in the described freeze-dried membrane cloth:

[0022] Betaine 26.5; Mannitol 17.6; Rain Bird's Nest Extract 0.8;

[0023] Hydrolyzed Sclerotium (SCLEROTIUM ROLFSSII) glue 2.5; Alcaligenes polysaccharide 1.6; Carboxymethyl chitosan 1.6; Hydrolyzed collagen 0.8; Egg white extract 0.5; Centella Asiatica (CENTELLA ASIATICA) extract 0.5; Hyaluronic acid Sodium acid 0.4; Licorice root extract 0.4; Gentiana (GENTIANA SCABRA) root extract 0.4; Sophora flavescens root extract 0.4; 0.03 for ceramide; 0.03 for ceramide; 0.03 for ceramide 2; 0.03 for ceramide 3;

Embodiment 2

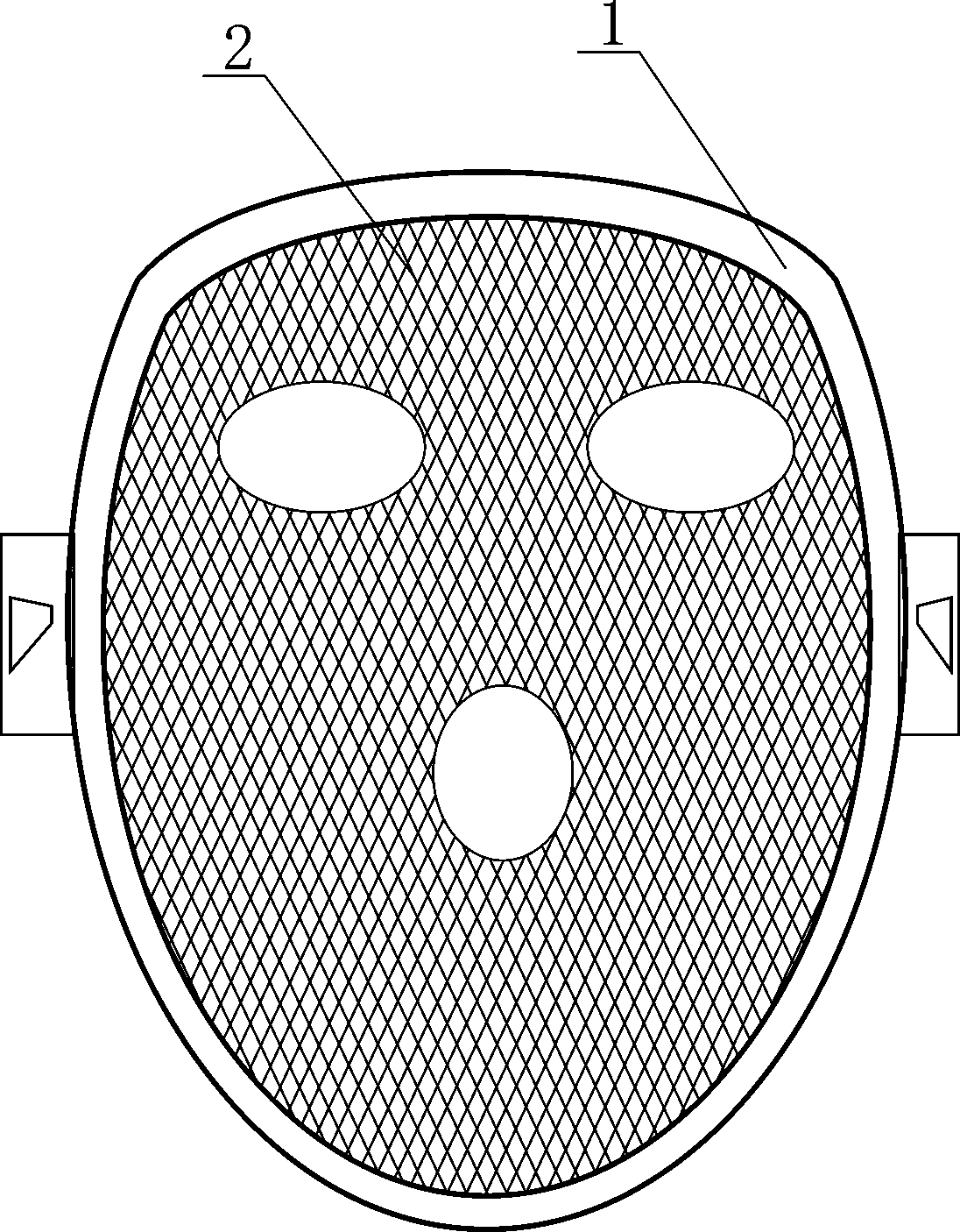

[0024] Embodiment 2: the surface of the heating mask 1 is covered with a layer of freeze-dried film cloth 2, which contains the following components in mass percentage:

[0025] Betaine 26.9; Mannitol 18.0; Hydrolyzed Sclerotium ROLFSSII Gum 2.9; Alcaligenes Polysaccharides 2.0; Carboxymethyl Chitosan 2.0; Rain Bird’s Nest Extract 1.0; 0.9; Centella Asiatica (CENTELLA ASIATICA) extract 0.9; sodium hyaluronate 0.6; licorice root extract 0.6; gentian (GENTIANA SCABRA) root extract 0.6; CNIDIUM MONNIERI) fruit extract 0.6; Artemisia annua (ARTEMISIA ANNUA) extract 0.6; β-glucan 0.07; ceramide 0.07; ceramide 2 0.07; ceramide 3 0.07; , and the balance is polyglycerol 10.

Embodiment 3

[0026] Embodiment 3: the surface of the heating mask 1 is covered with a layer of freeze-dried film cloth 2, and the freeze-dried film cloth 2 contains the following components by mass percentage:

[0027]Polyglycerol 10 42.7; Betaine 26.7; Mannitol 17.8; Hydrolyzed Sclerotium ROLFSSII gum 2.7; Alcaligenes polysaccharide 1.8; 0.9; egg white extract 0.7; centella asiatica (CENTELLA ASIATICA) extract 0.7; sodium hyaluronate 0.5; licorice root extract 0.5; gentian (GENTIANA SCABRA) root extract 0.5; Cnidium monnieri fruit extract 0.5; artemisia annua extract 0.5; β-glucan 0.05; ceramide 0.05; ceramide 2 0.05; ceramide 3 0.05; Amide 6 II 0.05.

[0028] The preparation methods of Example 1, Example 2, and Example 3 are the same, and now Example 3 is taken as an example to describe its preparation method.

[0029] The preparation method of the described freeze-dried film cloth of embodiment 3 comprises the following steps:

[0030] 1) Raw materials are divided into phase A and ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com