Method for improving blue light absorption by ink-jet printing quantum dot layer

A quantum dot layer and blue light absorption technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of ink inward sag, uneven color, and reduced light extraction efficiency, and achieve an increase in absorption value and improvement The effect of blue light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The method for improving the blue light absorption of the inkjet printing quantum dot layer in this embodiment is as follows:

[0049] S1: transfer or attach the blue light source to the TFT substrate to form a substrate with several blue light pixels;

[0050] S2: Preparation of the first layer of quantum dot ink layer (fluorescent layer)

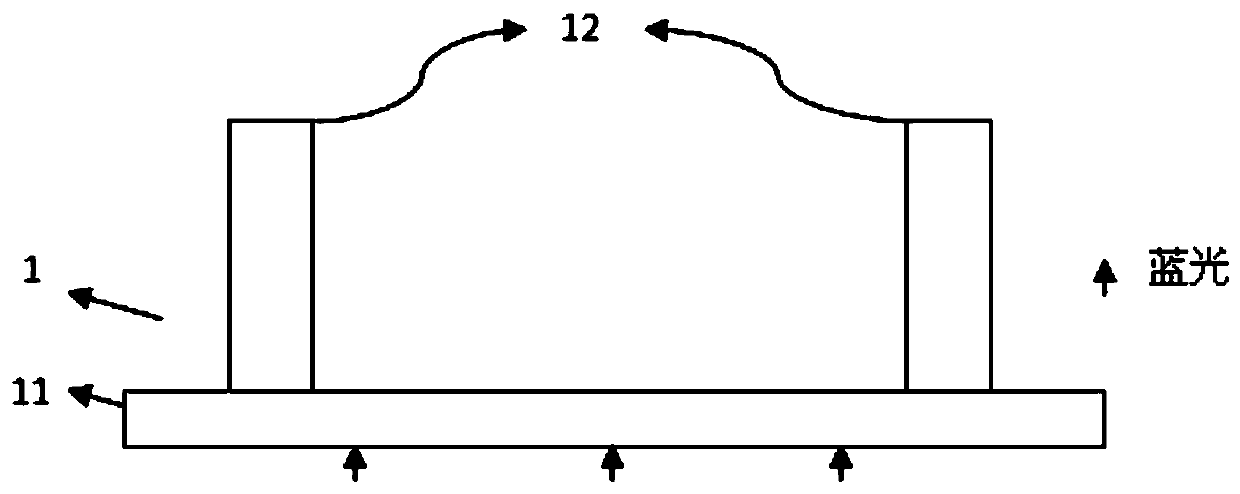

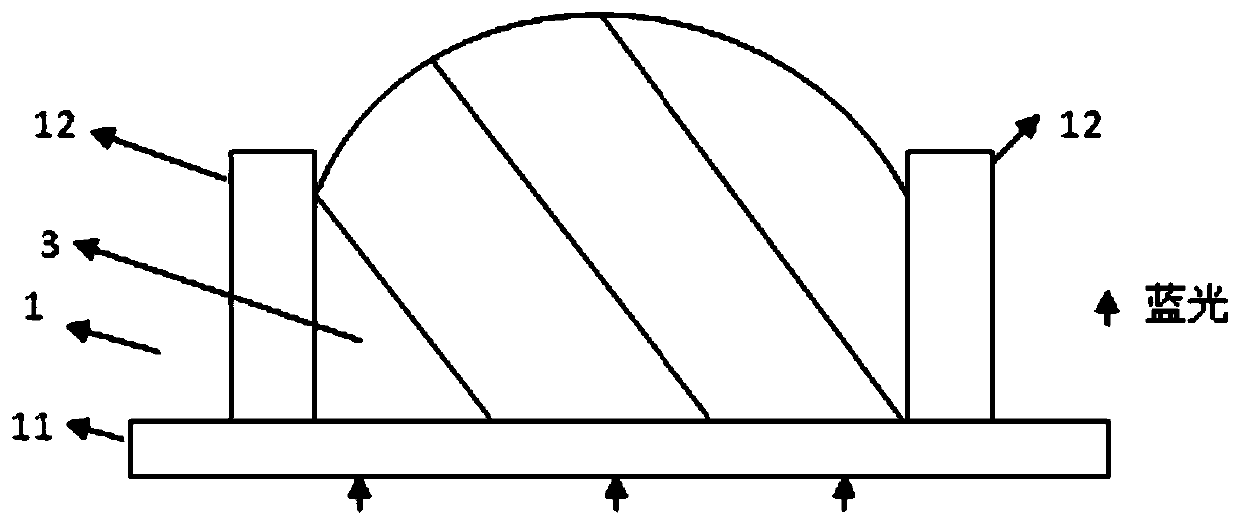

[0051] Filter 5ml of red quantum dot ink with a 220nm filter head, then add it to the ink cartridge, and install the ink cartridge on the printer to remove air bubbles. The quantum dot ink layer is obtained by printing the quantum dot ink into the QDCF device, and then photocuring in nitrogen. In other embodiments, quantum dot inks can also be printed (eg, screen printed) on QDCF devices. Such as Figure 4 As shown, when the quantum dot ink is printed or printed on the substrate 11 of the mold 1 , it is confined between the banks 12 of the mold 1 .

[0052] S3: Preparation of the second light diffusion layer

[0053] Recipe ing...

Embodiment 2

[0062] The method for improving the blue light absorption of the inkjet printing quantum dot layer in this embodiment is as follows:

[0063] S1: transfer or attach the blue light source to the TFT substrate to form a substrate with several blue light pixels;

[0064] S2: Preparation of the first layer of quantum dot ink layer (fluorescent layer)

[0065] Filter 5ml of red quantum dot ink with a 220nm filter head, then add it to the ink cartridge, and install the ink cartridge on the printer to remove air bubbles. The quantum dot ink layer can be obtained by printing the quantum dot ink into the QDCF device, and then curing it in nitrogen. The above curing method can be thermal curing, in one embodiment, the curing energy can be 500mj / cm 2 , The curing temperature is not higher than 150°C.

[0066] S3: Preparation of the second light diffusion layer

[0067] Recipe ingredients:

[0068] Diffusion powder (silicone microspheres): 6.25 parts

[0069] Silicone SCR1011: 93.75...

Embodiment 3

[0075] The method for improving the blue light absorption of the inkjet printing quantum dot layer in this embodiment is as follows:

[0076] S1: transfer or attach the blue light source to the TFT substrate to form a substrate with several blue light pixels;

[0077] S2: Preparation of the first layer of quantum dot ink layer (fluorescent layer)

[0078] Filter 5ml of green quantum dot ink with a 220nm filter head, then add it to the ink cartridge, and install the ink cartridge on the printer to remove air bubbles. The quantum dot ink layer can be obtained by printing the quantum dot ink into the QDCF device, and then curing it in nitrogen.

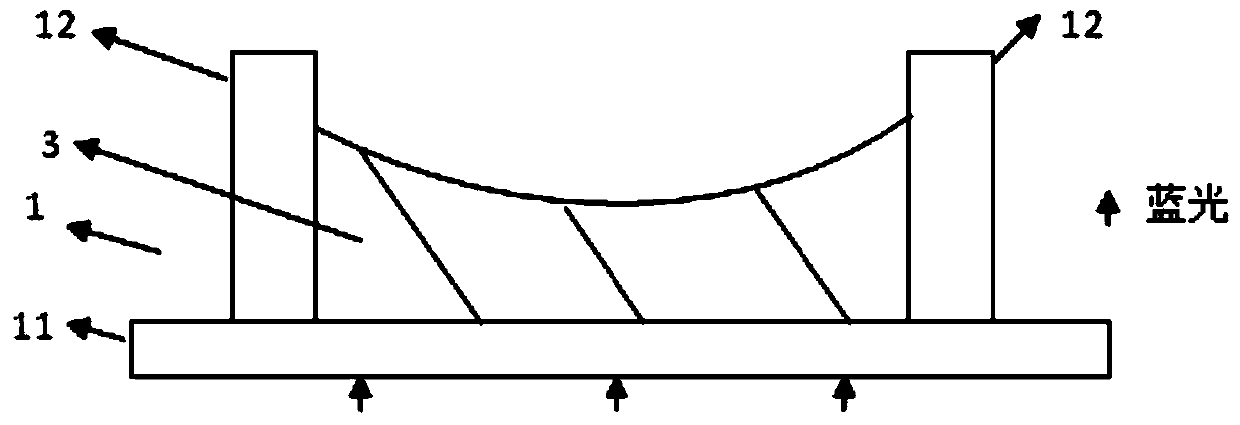

[0079] S3: Preparation of the second light diffusion layer

[0080] Titanium dioxide R902+: 11.2 parts

[0081] L-21 light curing adhesive: 88.8 parts

[0082] Add the diffusion powder titanium dioxide R902+ into L-21, grind and defoam in the yellow light environment, then scrape the mixed colloid on the surface of the green device t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com