LED chip and manufacturing method thereof, display panel and electronic device

A technology of LED chip and manufacturing method, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of affecting the yield rate of display panels and increasing the number of dead pixels of Micro-LED display panels, so as to improve the yield rate and reduce the number of bad spots. The probability of point generation, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

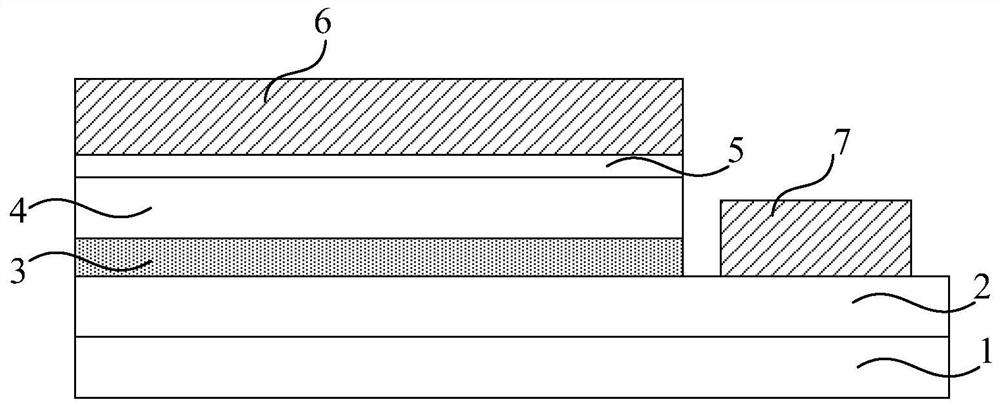

[0051] BACKGROUND OF THE INVENTION As the LED chip electrode size is reduced, the number of bad points in the Micro-LED display panel is multiplied, which affects the yield of the Micro-LED display panel. Now combined figure 1 Analyze the number of bad points in Micro-LED display panel:

[0052] During the manufacturing process of the actual micro-LED, in manufacturing figure 1 After the LED chip shown, the sapphire substrate 1 of the LED chip is removed, and a plurality of LED chips are powered on the drive backplane, thereby implementing the batch transfer of the LED chip.

[0053] Specifically, the bonding process is connected to the drive back plate by the welding process, thereby enabling the circuit unit on the drive back plate to the first contact electrode. 6 and the second contact electrode 7 loading voltage.

[0054] However, as the size of the LED chip is reduced, the size of the first contact electrode 6 and the second contact electrode 7 is reduced to several microns ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com