Metal cleaning fluid and cleaning method thereof

A metal cleaning and cleaning liquid technology, which is applied in the field of metal surface treatment, can solve problems such as secondary corrosion of metal copper materials, achieve the effects of reducing waste liquid discharge, reducing excessive erosion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

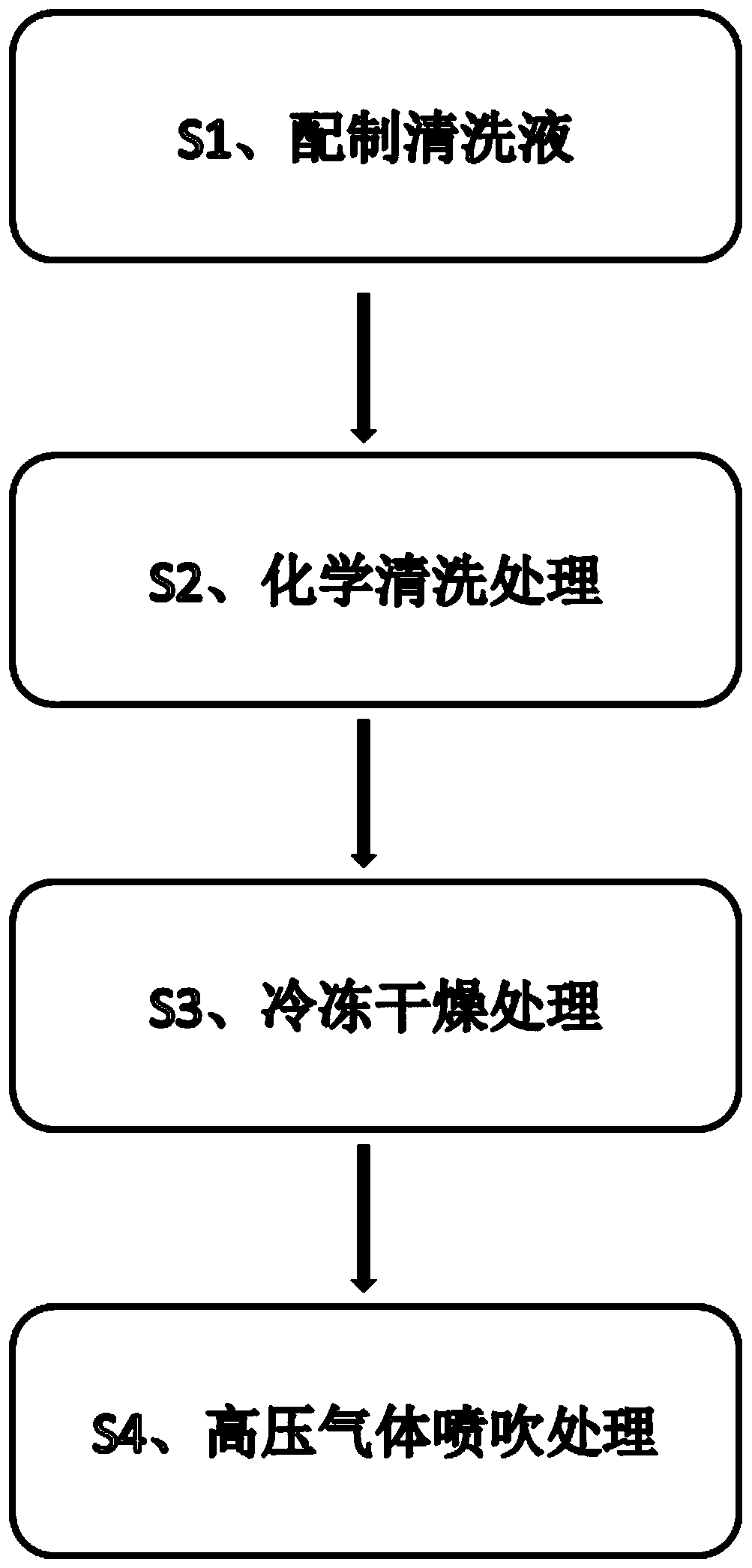

Method used

Image

Examples

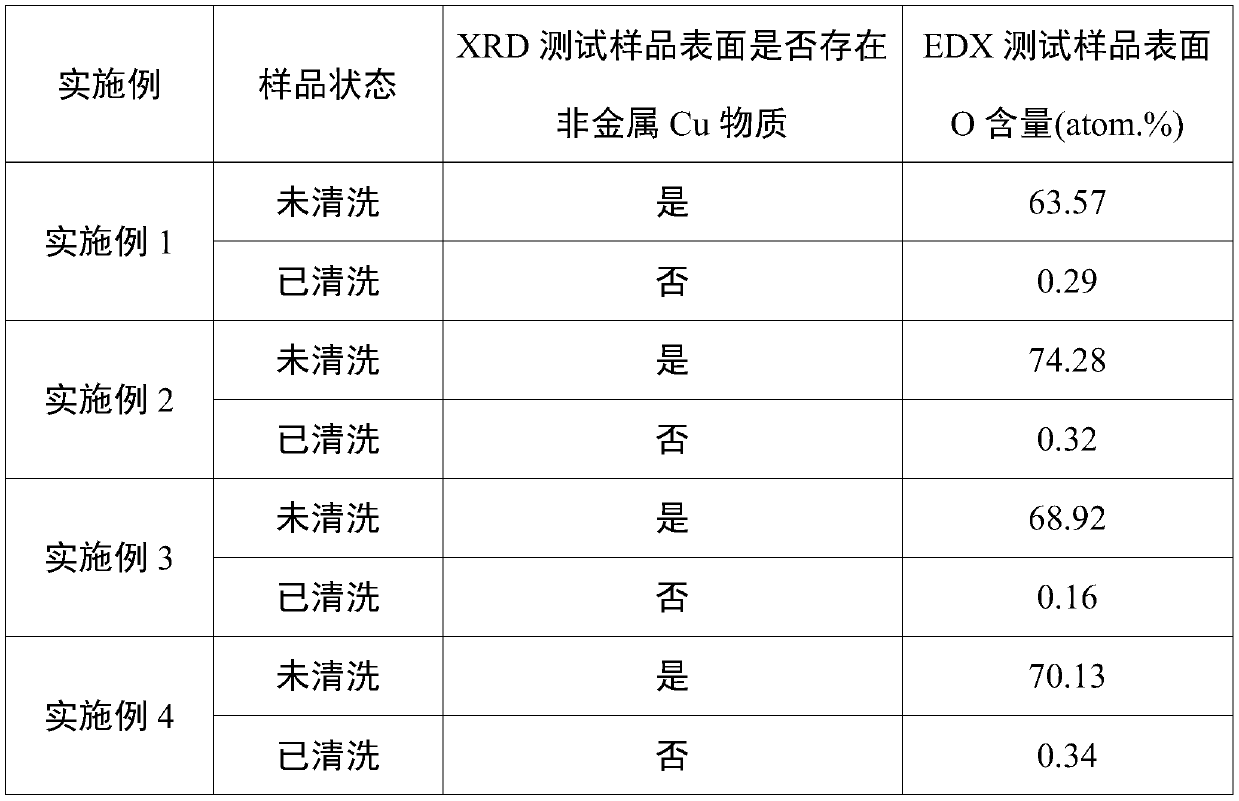

Embodiment 1

[0028] Preparation of cleaning solution: 80 parts of oxalic acid, 32 parts of citric acid, 53 parts of sodium dihydrogen phosphate, 18 parts of sodium pyrophosphate, 3 parts of tetrasodium iminodisuccinate, 0.5 parts of dopamine, 0.6 parts of agar, 90 parts of ethanol, with 820 1 part deionized water as solvent. Prepare the cleaning solution at a temperature of 75°C. After the preparation is completed, stir the cleaning solution quickly for 2 hours when the temperature of the cleaning solution drops to 25-28°C.

[0029] Chemical cleaning treatment: Take the metal copper plate with natural corrosion products on the surface and hang it on one end of the ultrasonic vibration head, then immerse the metal copper plate in the cleaning solution, keep the temperature of the cleaning solution at 25°C, turn on the ultrasonic vibration head vibration frequency of 100kHz, and clean for 15 minutes.

[0030] Freeze-drying: Take the metal copper plate out of the cleaning solution and remove ...

Embodiment 2

[0033] Preparation of cleaning solution: 120 parts of oxalic acid, 43 parts of citric acid, 62 parts of sodium dihydrogen phosphate, 20 parts of sodium pyrophosphate, 3.5 parts of tetrasodium iminodisuccinate, 0.6 parts of dopamine, 0.9 parts of agar, 105 parts of ethanol, and 850 parts 1 part deionized water as solvent. Prepare the cleaning solution at a temperature of 75°C. After the preparation is completed, stir the cleaning solution quickly for 3 hours when the temperature of the cleaning solution drops to 25-28°C.

[0034] Chemical cleaning treatment: Take the metal copper plate with natural corrosion products on the surface and hang it on one end of the ultrasonic vibration head, then immerse the metal copper plate in the cleaning solution, maintain the temperature of the cleaning solution at 35°C, turn on the ultrasonic vibration head vibration frequency of 100kHz, and clean for 20 minutes.

[0035] Freeze-drying: Take the metal copper plate out of the cleaning solutio...

Embodiment 3

[0038] Preparation of cleaning solution: 80 parts of oxalic acid, 32 parts of citric acid, 53 parts of sodium dihydrogen phosphate, 18 parts of sodium pyrophosphate, 3 parts of tetrasodium iminodisuccinate, 0.5 parts of dopamine, 0.6 parts of agar, 90 parts of ethanol, with 820 1 part deionized water as solvent. Prepare the cleaning solution at a temperature of 75°C. After the preparation is completed, stir the cleaning solution quickly for 2 hours when the temperature of the cleaning solution drops to 25-28°C.

[0039] Chemical cleaning treatment: Take the metal copper plate with natural corrosion products on the surface and hang it on one end of the ultrasonic vibration head, then immerse the metal copper plate in the cleaning solution, keep the temperature of the cleaning solution at 25°C, turn on the ultrasonic vibration head vibration frequency of 100kHz, and clean for 15 minutes.

[0040] Freeze-drying: Take the metal copper plate out of the cleaning solution and remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com