a kind of sio 2 @c Nanocomposite material and its preparation method

A nano-composite material and nano-composite technology are applied in the field of energy material preparation, which can solve the problems of poor toughness and low aerogel strength, and achieve the effects of improving strength and toughness, simple preparation method and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First disperse or dissolve ethyl orthosilicate in ethanol and hydrochloric acid, mix and fully stir at room temperature for more than half an hour. Subsequently, the solution was reacted at 60° C. for 2 hours. After that, 3ml of ammonia water was added dropwise to the solution, and after stirring at room temperature for half an hour, it was sealed and transferred to a dry environment (relative humidity less than 60%) for aging for about 10 days. The resulting SiO 2 The airgel product was dried and ground into powder, and 200 mg was placed in a quartz tube for chemical vapor deposition. Heating to 690°C in an argon atmosphere; then passing through acetylene gas, and reacting at this temperature for 1 hour to obtain SiO 2 @C core-shell nanostructure thermal insulation material.

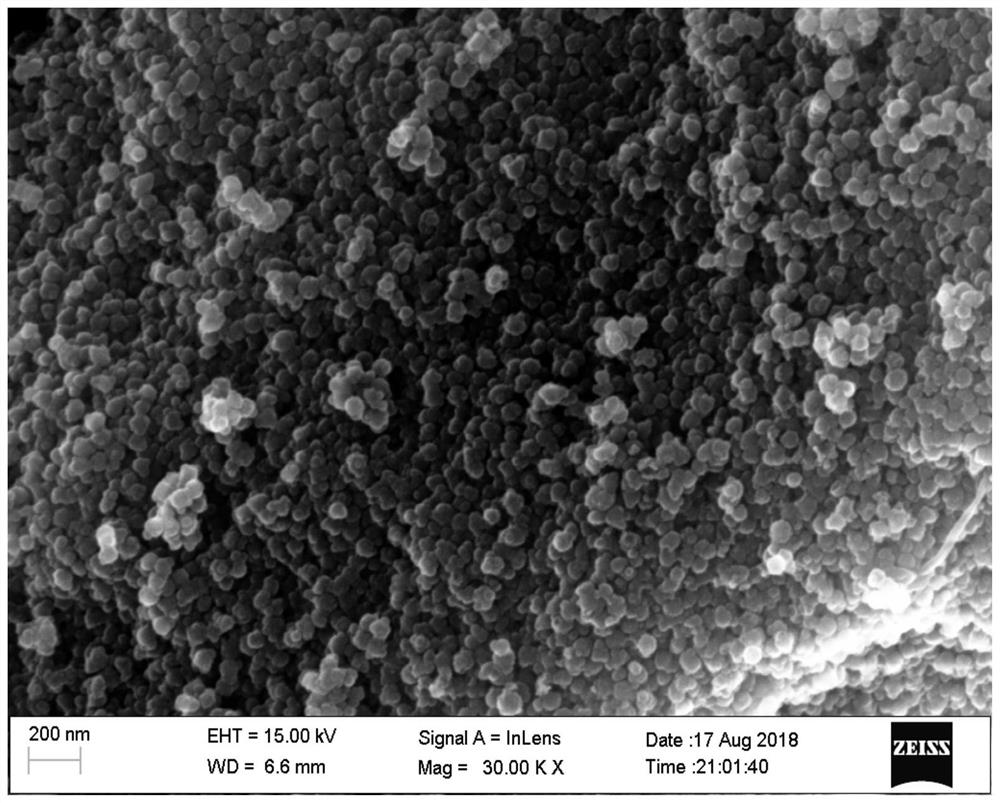

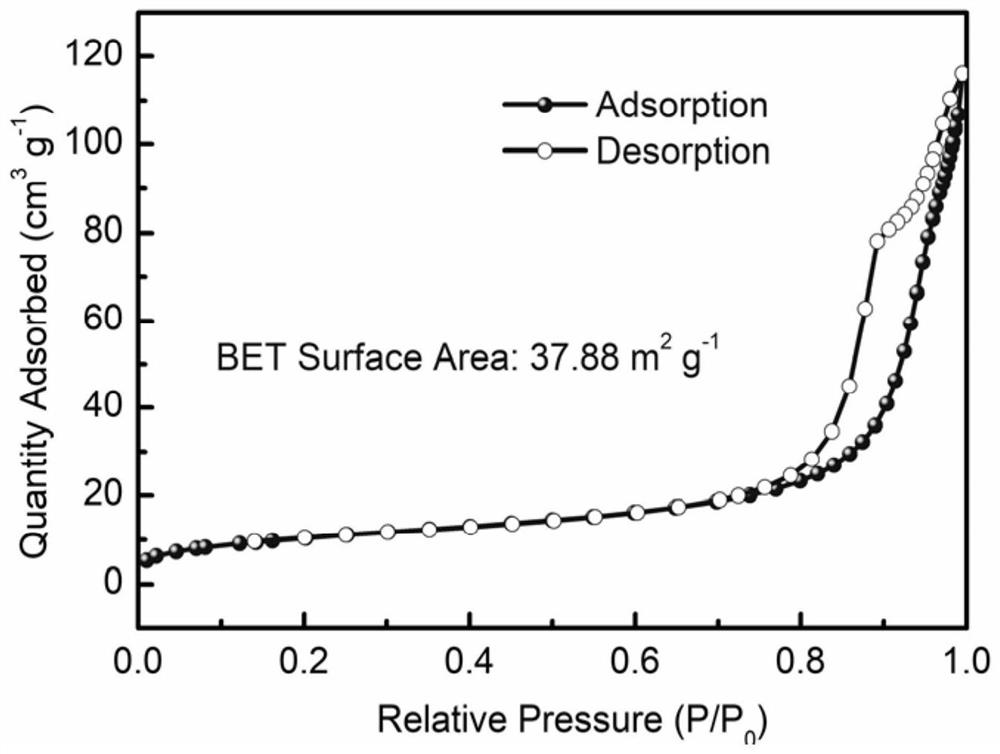

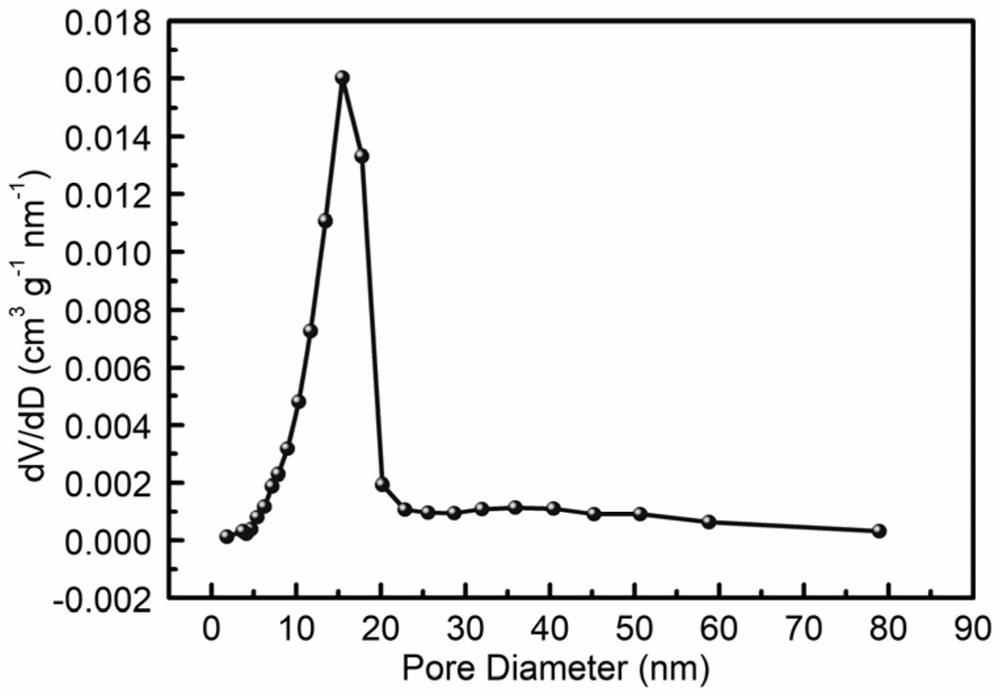

[0032] SiO obtained by this method 2 SEM characterization of @C nanocomposites as figure 1 shown. N of the material 2 The isotherm adsorption-desorption curve is as figure 2 shown. The ...

Embodiment 2

[0034] First disperse or dissolve ethyl orthosilicate in ethanol and hydrochloric acid, mix and fully stir at room temperature for more than half an hour. Subsequently, the solution was reacted at 60° C. for 2 hours. After that, 3ml of ammonia water was added dropwise to the solution, and after stirring at room temperature for half an hour, it was sealed and transferred to a dry environment (relative humidity less than 60%) for aging for about 10 days. The resulting SiO 2 The airgel product was dried and ground into powder, and 200 mg was placed in a quartz tube for chemical vapor deposition. Heating to 890°C in an argon atmosphere; then, pass through acetylene gas and react at this temperature for 1 hour to obtain SiO 2 @C core-shell nanostructure thermal insulation material.

[0035] SiO obtained by this method 2 SEM characterization of @C nanocomposites as Figure 4 shown. N of the material 2 The isotherm adsorption-desorption curve is as Figure 5 shown. The pore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com