An adjustable steel plate surface grinding and derusting device

An adjustable, steel plate technology, used in grinding drive devices, grinding machines, grinding workpiece supports, etc., can solve the problems of inability to adjust the steel plate flexibly, and can not achieve high-efficiency double-sided rust removal of the steel plate, so as to achieve convenient adjustment and rust removal. The effect is sufficient and applicable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

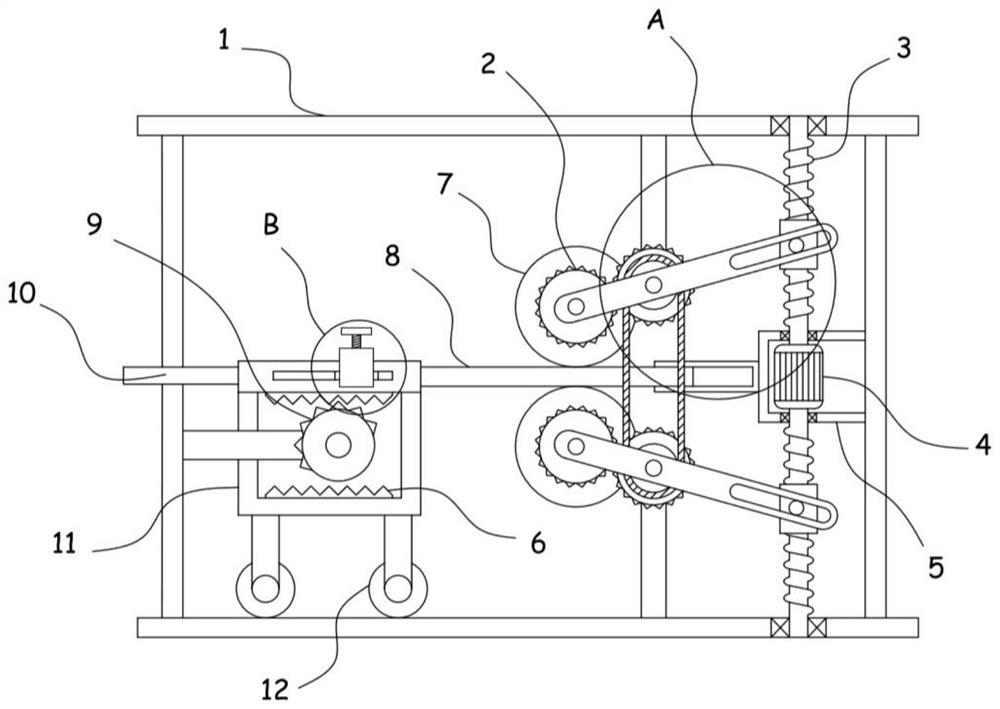

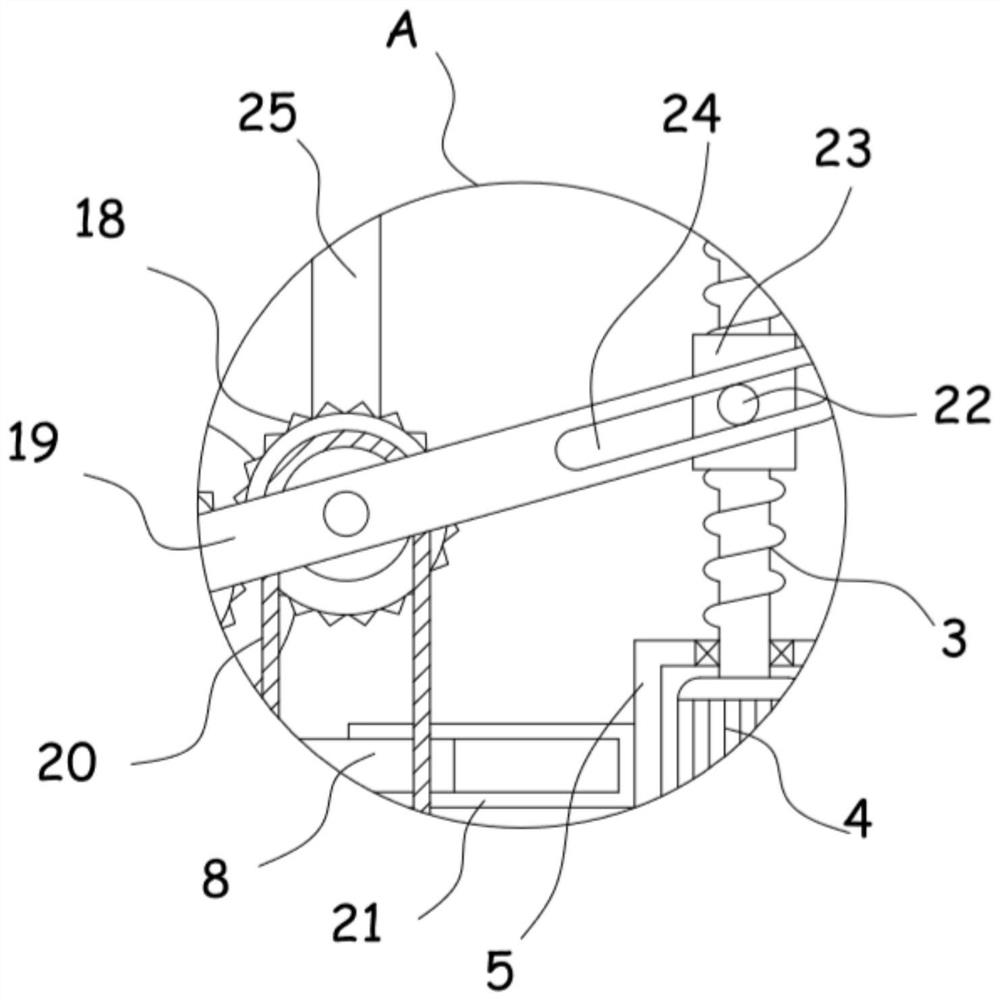

[0023] see Figure 1-5 , an adjustable steel plate surface grinding rust removal device, including a support frame 1, a motor frame 5 is fixed on the support frame 5, a biaxial motor 4 is arranged in the motor frame 5, and a motor driven by a transverse reciprocating mechanism is arranged in the support frame 1 For the clamping mechanism for clamping the steel plate 8, the biaxial motor 4 is driven and connected with two adjustment mechanisms, and the two adjustment mechanisms are connected with a grinding roller 7 for grinding the steel plate 8. The adjustment mechanism is provided with a A drive mechanism that drives the grinding roller 7.

[0024] When the device is derusting the steel plate 8, the steel plate 8 is clamped and fixed by the clamping mechanism provided. Driven by the transverse reciprocating mechanism, the clamping mechanism and the steel plate 8 move relatively laterally with respect to the grinding roller 7 to realize rotation. The grinding roller 7 can gr...

Embodiment 2

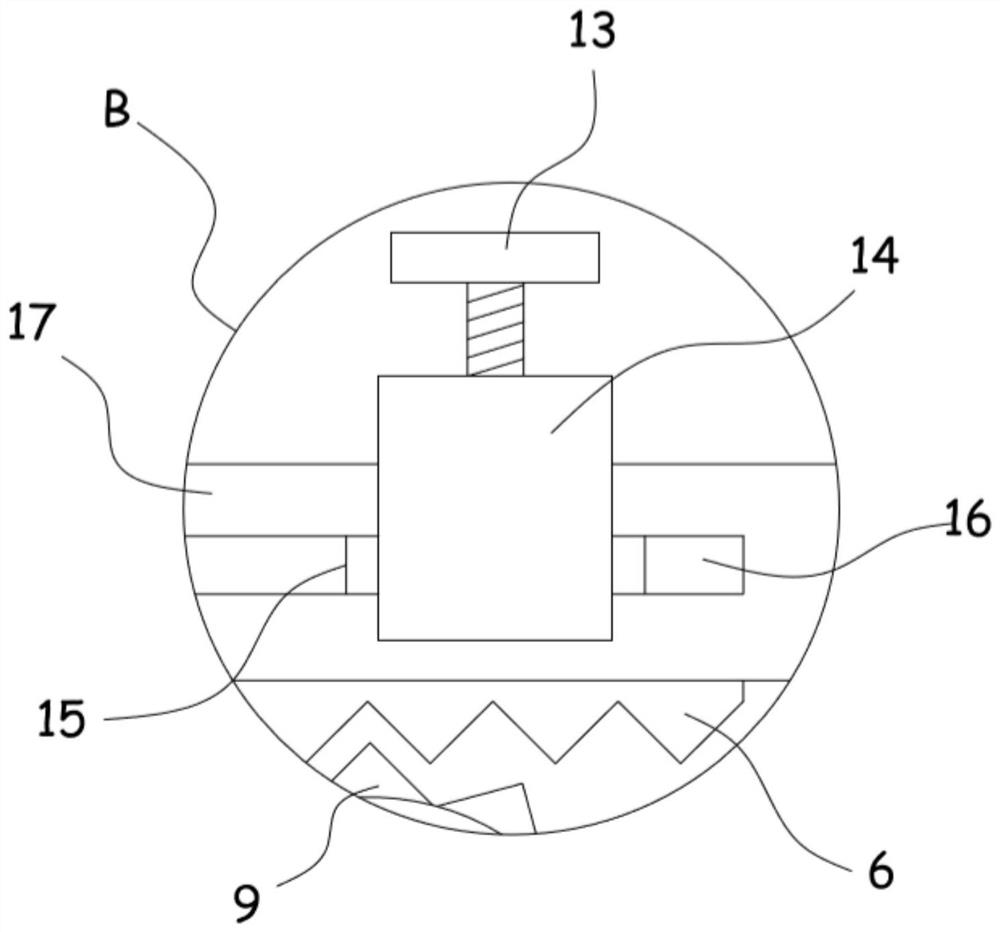

[0029] On the basis of Embodiment 1, in order to achieve a stable clamping effect on the steel plate 8, the clamping mechanism of the device includes a clamping seat 17 for the clamping of the steel plate 8, and a sliding frame 14 is slidably installed on the clamping seat 17. The threaded connection on the frame 14 is provided with a locking stud 13 abutting against the steel plate 8 .

[0030] When the steel plate 8 is clamped, the steel plate 8 is placed on the clamping seat 17, the position of the sliding frame 14 on the clamping seat 17 is adjusted, and the rotating locking stud 13 is screwed downward relative to the sliding frame 14 to realize the clamping of the steel plate 8. The locking and abutment of 8 ensures the stability of the rust removal process of the steel plate 8. The lateral wall of the clamping seat 17 is provided with a guide groove 16, and the guide groove 16 is slidably embedded with a guide block 15 fixed on the inner wall of the sliding frame 14. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com