A 3D printing scraper integrated device and method for improving workpiece forming quality

A 3D printing and forming quality technology, applied in the field of additive manufacturing, can solve the problems of local protrusion accumulation on the forming plane of parts, printing failure of parts, etc., and achieve the effect of improving the possibility and the forming quality of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

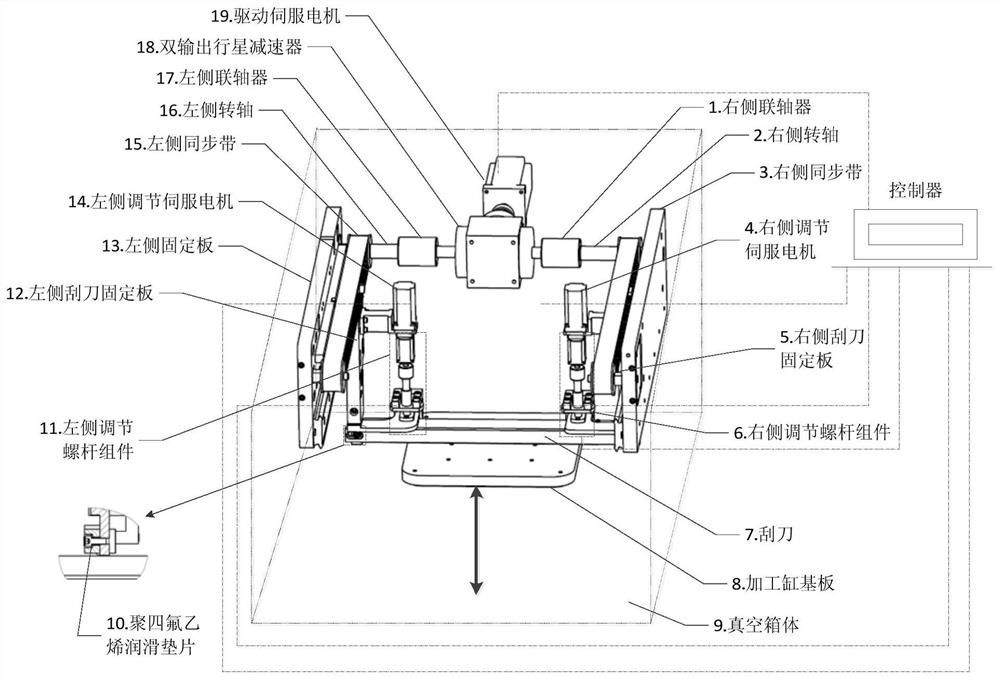

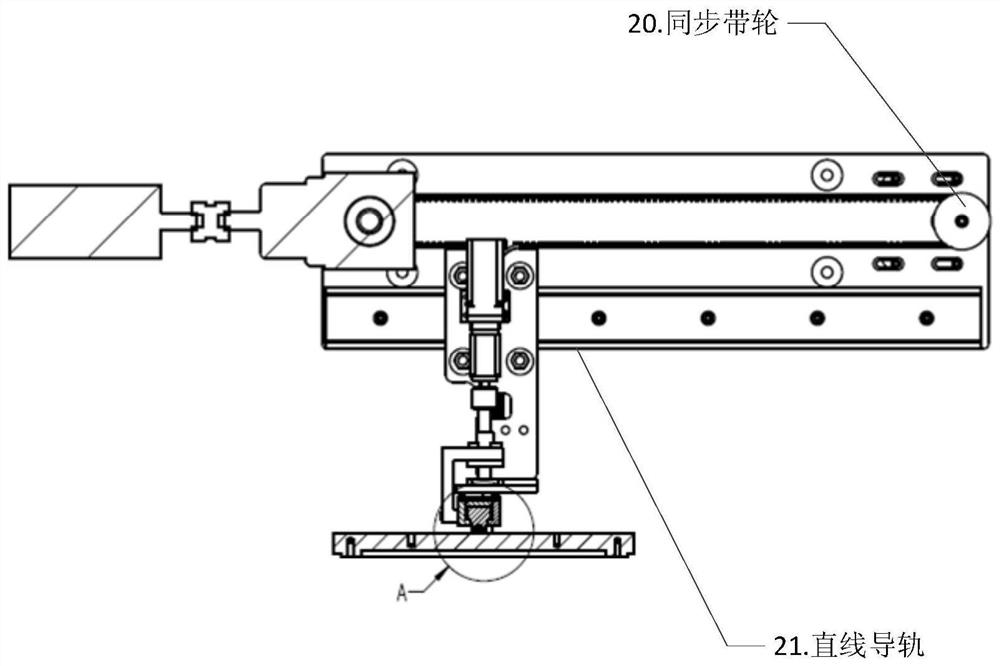

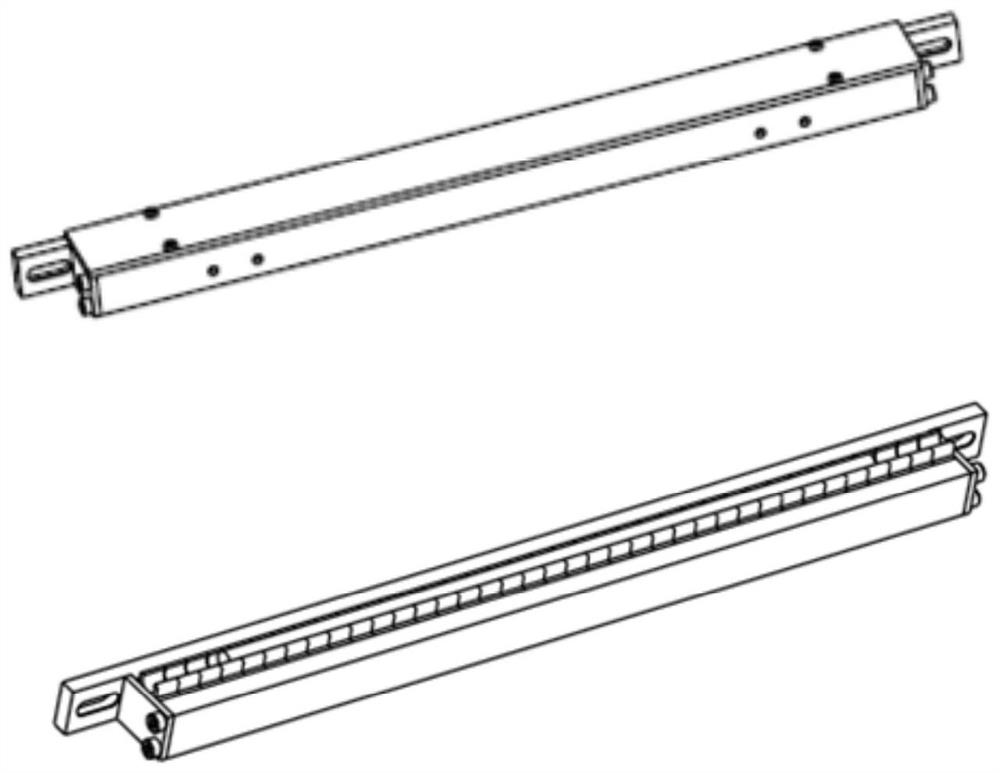

[0036] The following will combine figure 1 , 2 , 3, 4, 5, 6 further describe in detail the 3D printing scraper integration device and method for improving the forming quality of workpieces of the present invention.

[0037] In order to solve the problem that in the process of 3D printing, the splashes are sintered layer by layer by the energy source to form local protrusions, and the local protrusions accumulate layer by layer. In severe cases, the rubber strip of the scraper falls off, which directly leads to the failure of part forming. The solution of the present invention is simple, practical and reliable, and provides a 3D printing scraper integrated device and method for improving the forming quality of workpieces, which can realize high-quality forming of workpieces.

[0038] figure 1 , 2It is a general diagram and cross-sectional view of a 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com