Water vapor and fine particle pollutant synergistic removal device based on pressure swing condensation

A collaborative removal device and fine particle technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high operating costs, large energy consumption, heat transfer efficiency of heat exchangers, and high anti-blocking technology requirements problems, to achieve high water collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

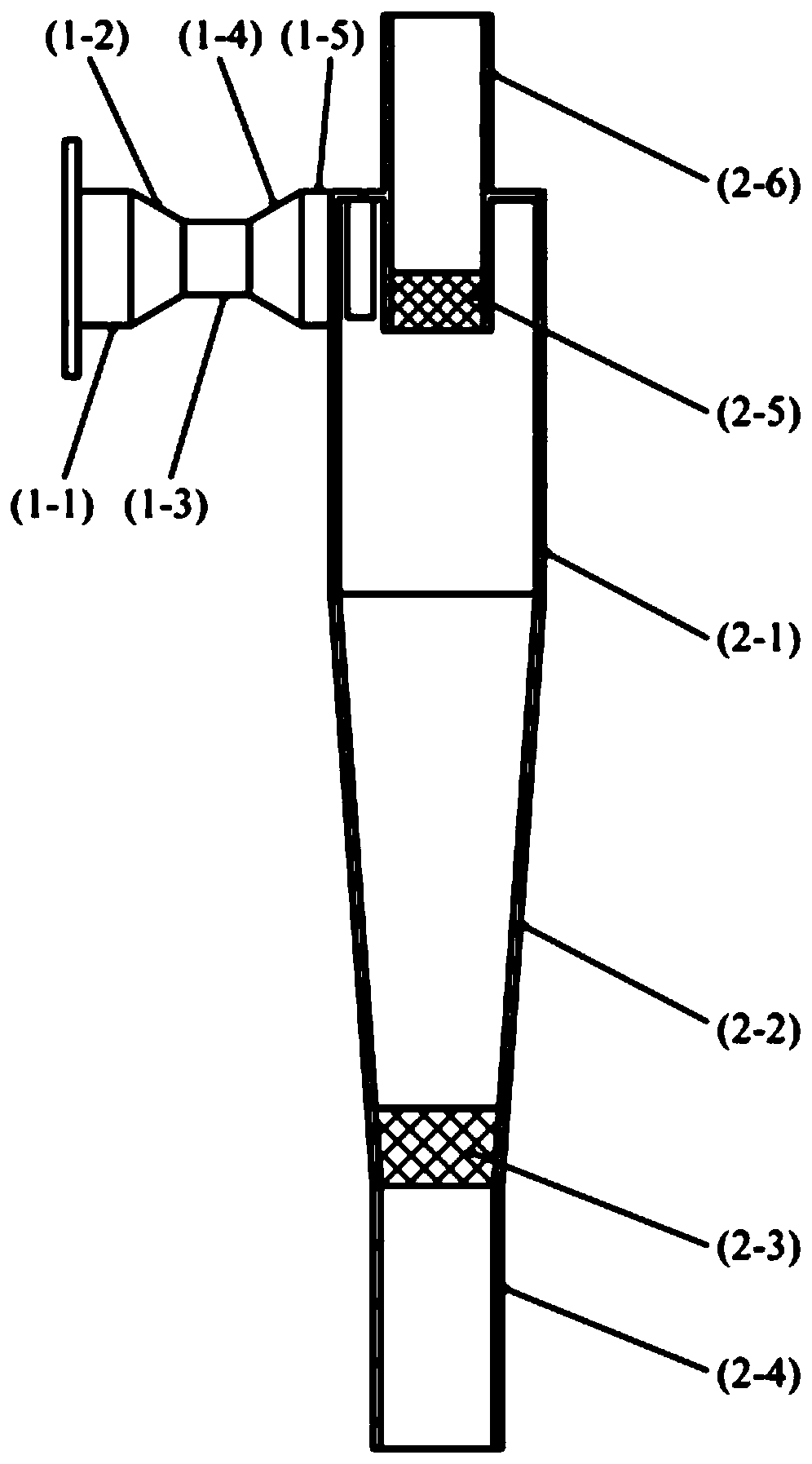

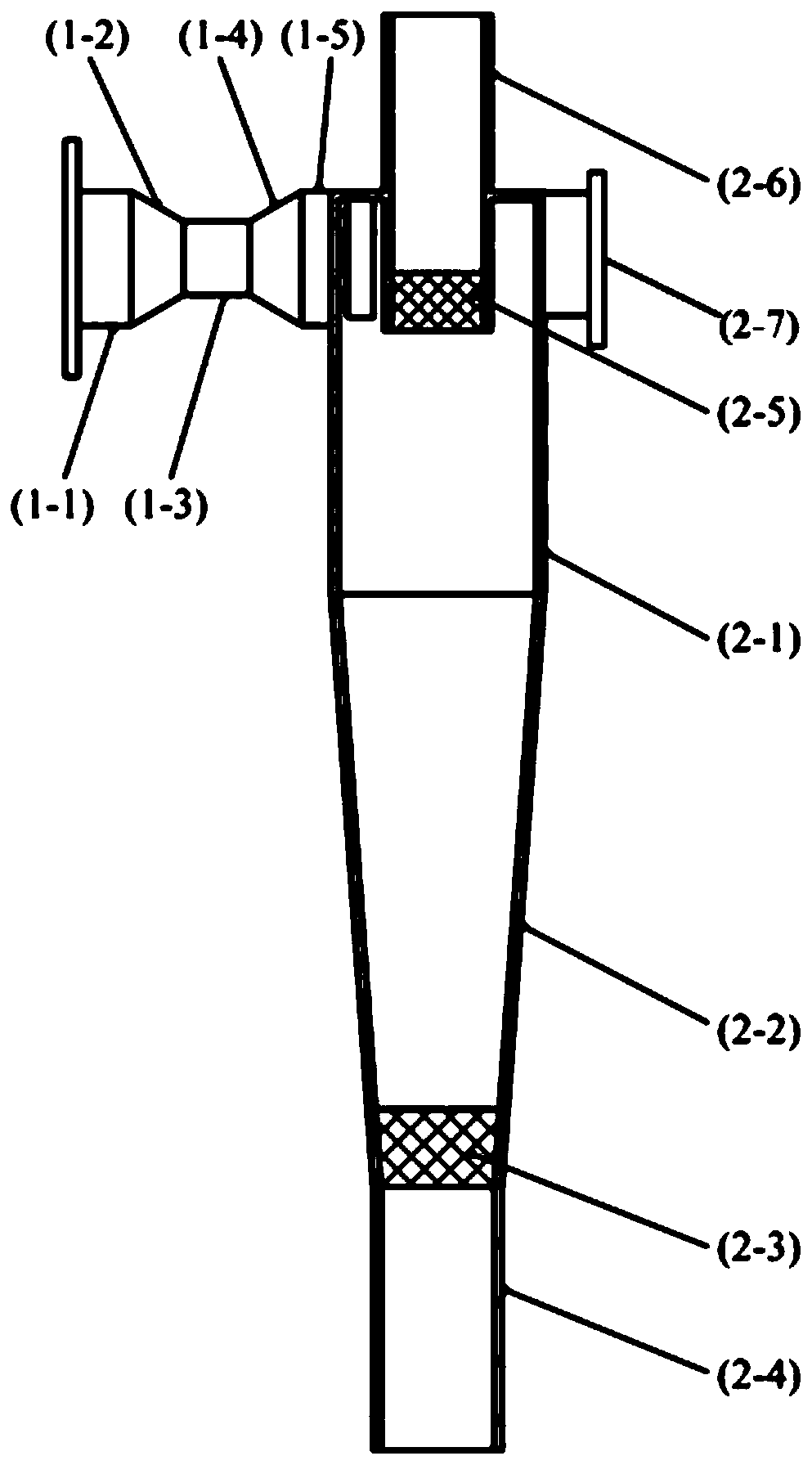

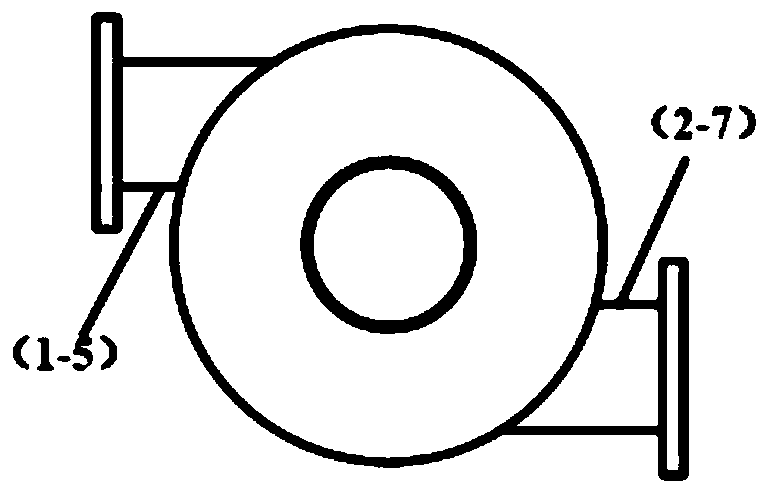

[0026] Such as Figure 1-Figure 4 As shown, the present invention provides a cooperative removal device for water vapor and fine particle pollutants based on pressure swing condensation, including a separator and a steam pressure swing condensation part arranged at the front end of the separator, and the separator includes a The overflow pipe 2-6 and the underflow pipe 2-4 arranged at the bottom, the vapor pressure change condensation part includes the inlet pipe 1-1, the closing pipe 1-2, the throat pipe 1-3, the expansion pipe 1-4 and the connection Pipe 1-5, the saturated steam passes through the inlet pipe 1-1, closing pipe 1-2, throat pipe 1-3, expansion pipe 1-4 and connecting pipe 1-5 in sequence, and changes pressure, condenses into small droplets and then tangentially After entering the separator, the small droplets coalesce, grow up and collect the fine particles in the separator, the droplets are discharged downward from the bottom flow pipe 2-4, and the gas is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com