Nutritious corbicula fluminea juice and preparation method thereof

A clam and nutrition technology, applied in the field of clam juice and its preparation, can solve the problem of reducing the nutritional value and sensory quality of clam extract, the inability to fully extract high molecular compounds from clam meat, and the inability to comprehensively utilize multiple clam meat. Nutritional components and other issues, to achieve the effect of improving storage stability, shortening enzymatic hydrolysis time, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

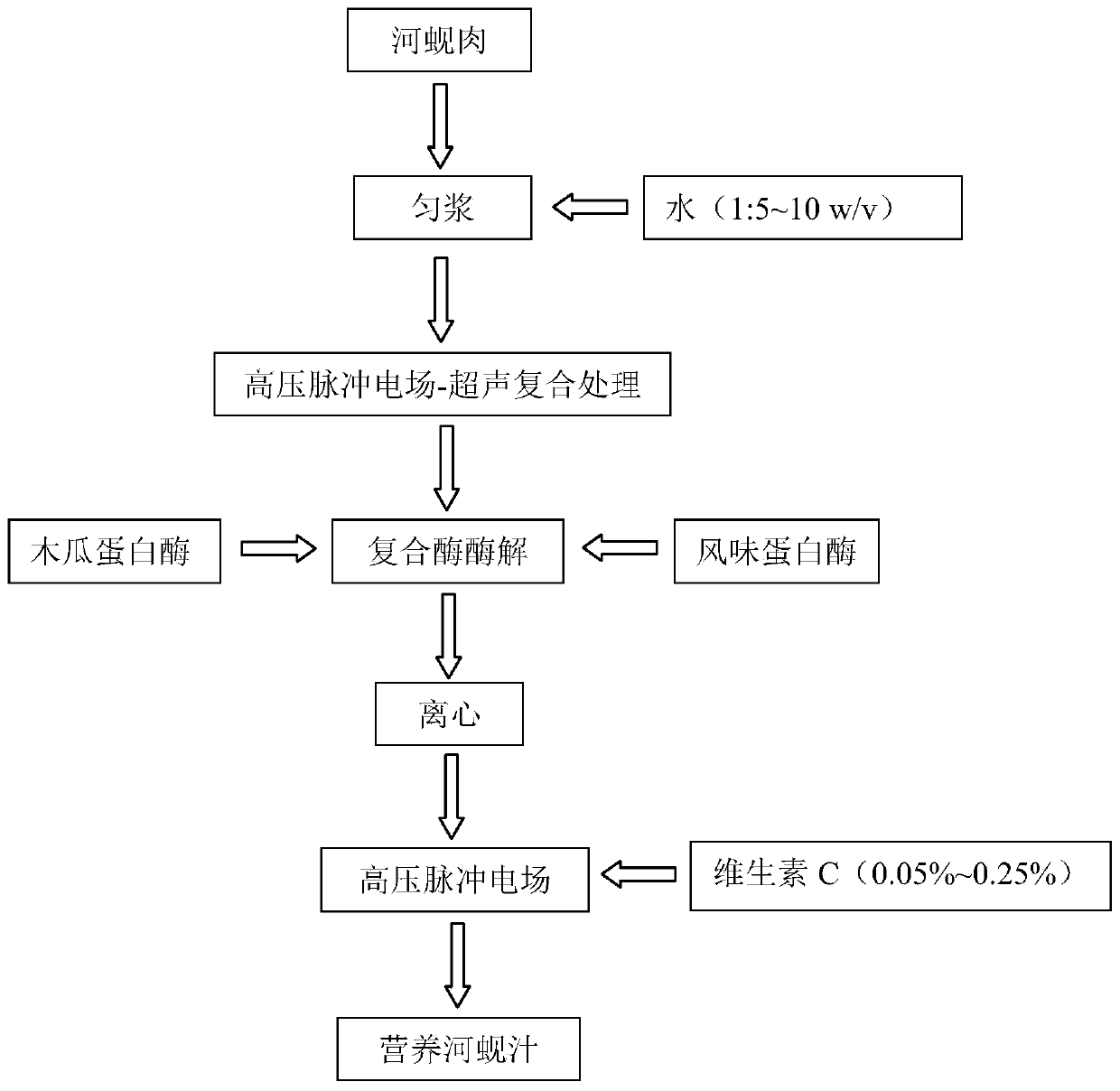

Method used

Image

Examples

Embodiment 1

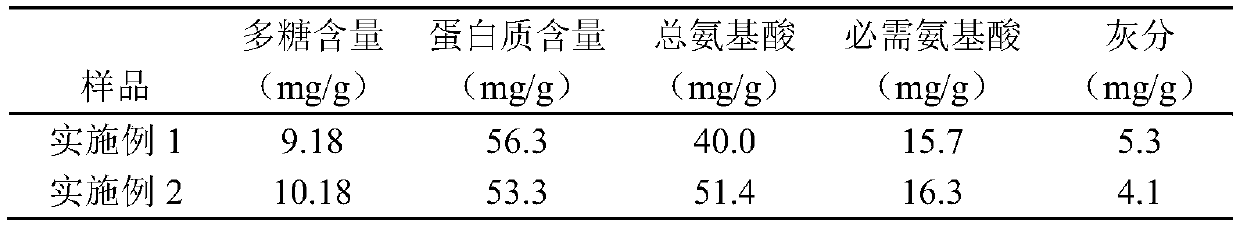

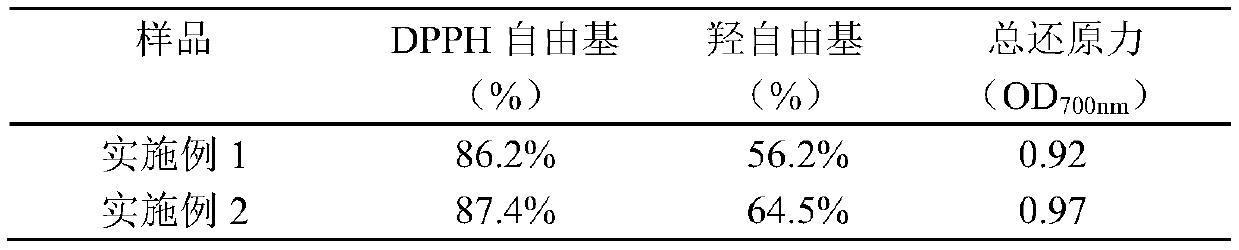

[0018] Example 1: Weigh 200g of river clam meat, add 1L of water, and put it into a homogenizer at the same time for homogenization. The operating conditions are homogenization speed 10000rpm, temperature 20°C, homogenization for 1 minute, and the river clam is obtained. Minced clams. The minced clam meat is transported by a liquid pump to a high-voltage pulsed electric field-ultrasonic composite processing equipment for operation. The operating conditions are pulse width of 2 μs, frequency of 100 Hz, electric field strength of 5 kV / cm, and processing time of 5 minutes; ultrasonic processing conditions As follows: the power is 300W, the ultrasonic time is 5 minutes, and the temperature is 20°C, and the first juice of the river clam is obtained. Add compound protease to the primary juice of clams to carry out stirring enzymolysis process. The operating conditions are that the ratio of papain and flavor protease is 1:0.2 (w / w), the amount of compound enzyme added is 2g (1%), and...

Embodiment 2

[0019]Example 2: Weigh 200g of river clam meat, add 2L of water, and put it into a homogenizer at the same time for homogenization operation. The operating conditions are homogenization speed of 20000rpm, temperature of 40°C, homogenization for 5 minutes, and the river clam is obtained. Minced clams. The minced clam meat is transported to the high-voltage pulsed electric field-ultrasonic composite processing equipment through a liquid pump for operation. The operating conditions are pulse width of 10 μs, frequency of 1000 Hz, electric field strength of 20 kV / cm, and processing time of 30 minutes; ultrasonic processing conditions As follows: the power is 600W, the ultrasonic time is 30 minutes, and the temperature is 40°C, and the first juice of the river clam is obtained. Add complex protease to the primary juice of clams for stirring enzymolysis process, the operating conditions are papain and flavor protease ratio of 1:1, compound enzyme addition amount is 6g (3%), enzymolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com