U-shaped composite permanent magnet motor

A permanent magnet motor and composite magnet technology, which is applied in the direction of motors, electromechanical devices, electric vehicles, etc., can solve the problems of difficult constant power speed increase, low power and torque density, large stator loss, etc., and achieve a wide range of constant power speed, Effects of improving efficiency and power, and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the scope of protection of the present invention. The commas in all represent the relationship between and, and the English letters in the present invention are case-sensitive.

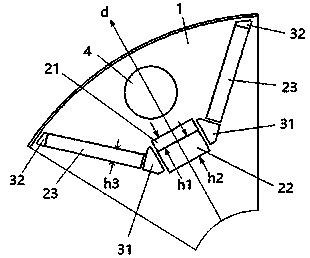

[0019] Such as figure 1 As shown, a U-shaped compound permanent magnet motor provided by the embodiment of the present invention includes a stator (not shown in the figure) and a rotor 1. The rotor is provided with a plurality of permanent magnet units, and each permanent magnet unit surrounds the rotor. Axisymmetric layout at intervals, characterized by:

[0020] The permanent magnet unit includes three inline permanent magnet slots, one of which is a middle permanent magnet slot, and the other two perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com