Method for predicting cigarette combustion cone falling tendency

A technology for burning cones and cigarettes, which is applied in the direction of chemical analysis using combustion, can solve the problems of inappropriate product quality control, poor timeliness, and large workload, and achieves improved production and R&D efficiency, simplicity and accuracy, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

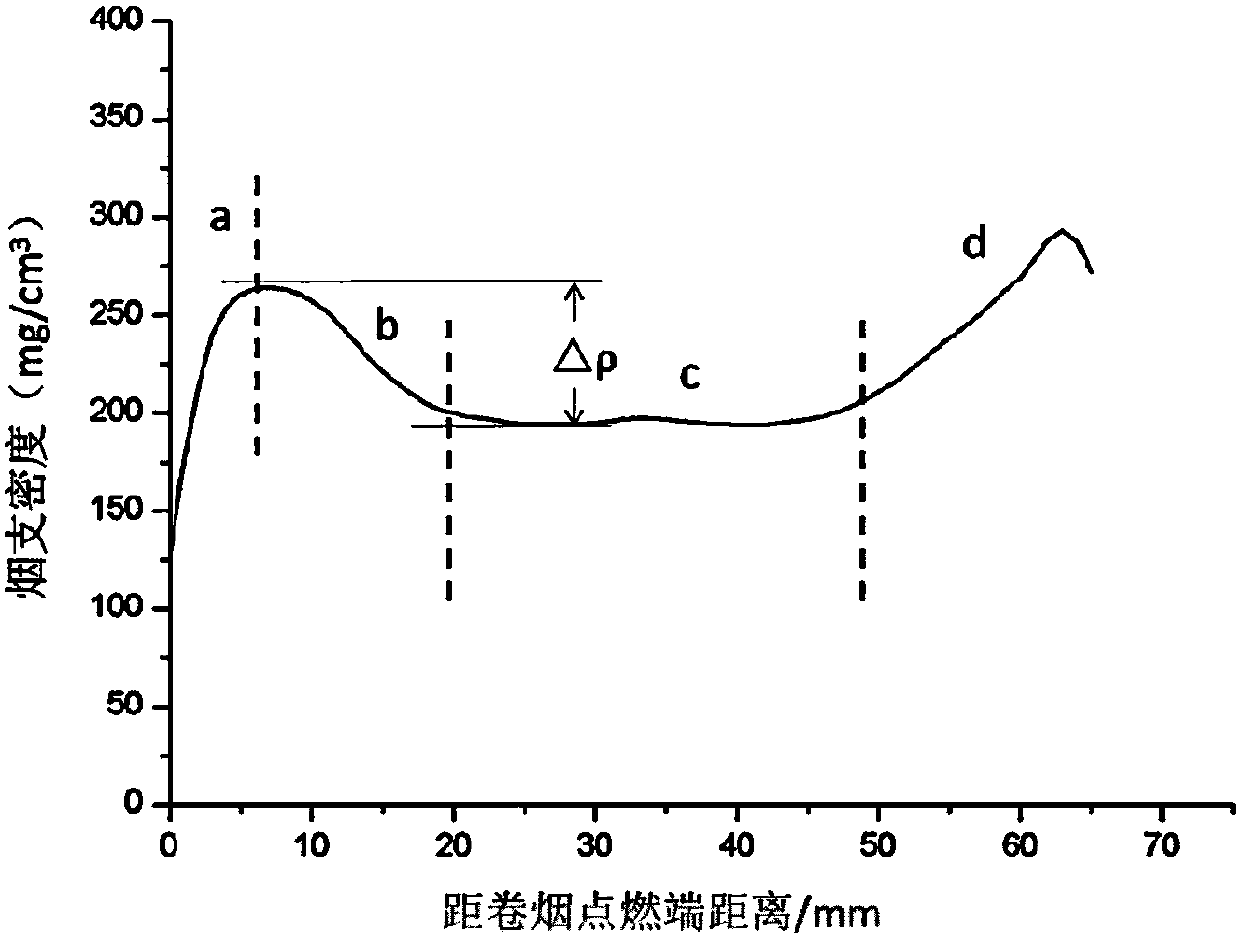

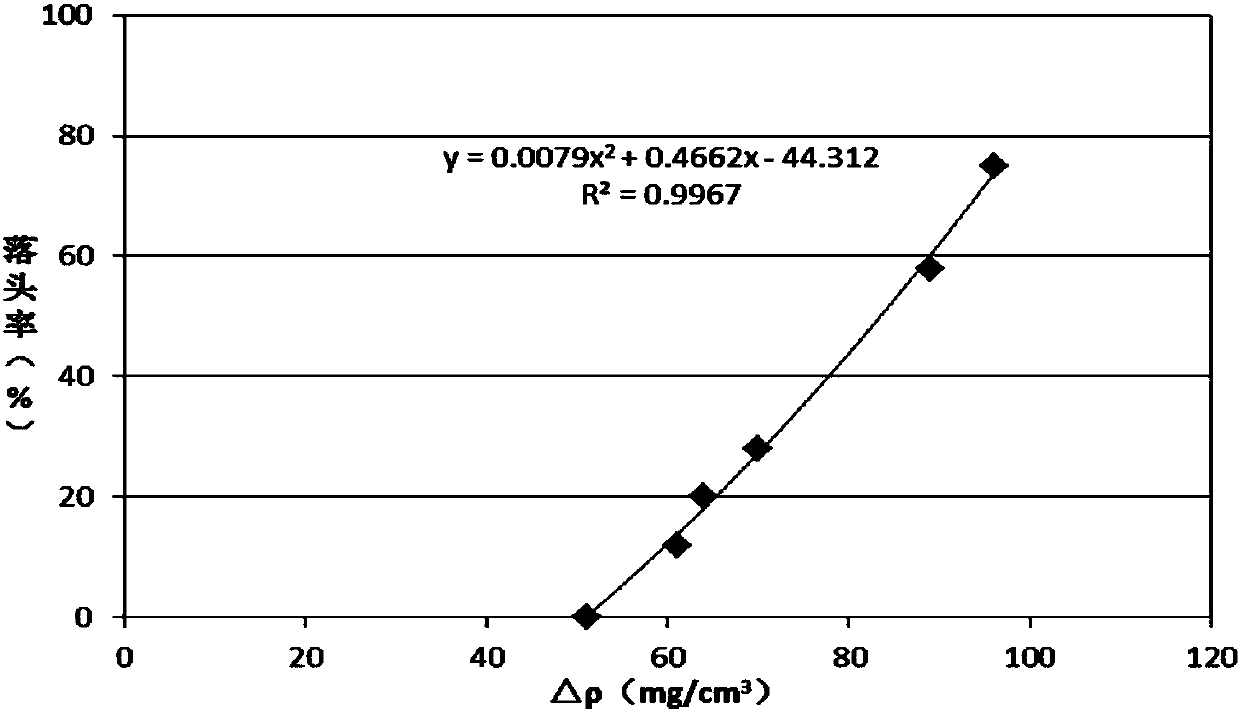

[0030] Take brand A production sample 1, measure the tobacco density distribution by microwave method, and calculate the Δρ value to be 89.40 mg / cm 3 , and substituted into the above equation, the predicted head drop rate is 60.51%, and the measured head drop rate is 58%.

Embodiment 2

[0032] Taking the production sample 2 of brand A (changing the structure of the leveling disk, and fixing other parameters), the density distribution of cut tobacco was measured by microwave method, and the calculated Δρ value was 70.18 mg / cm 3 , and substituted into the above equation, the predicted head drop rate is 27.32%, and the measured head drop rate is 28%.

Embodiment 3

[0034] Take the production sample 3 of brand A (adjust the size distribution of shredded tobacco, and fix other parameters), measure the density distribution of shredded tobacco by microwave method, and calculate the value of Δρ to be 64.60 mg / cm 3 , and substituted into the above equation, the predicted head drop rate is 18.77%, and the measured head drop rate is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com