High-entropy quinary alloy with good high strength and high plasticity matching performance and preparation method thereof

A high-entropy alloy and plasticity technology, applied in the field of high-entropy alloy and its preparation, can solve problems such as poor matching of strength and toughness of high-entropy alloy, and achieve the effects of good fluidity and casting performance, narrow crystallization range, and simple and reliable preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

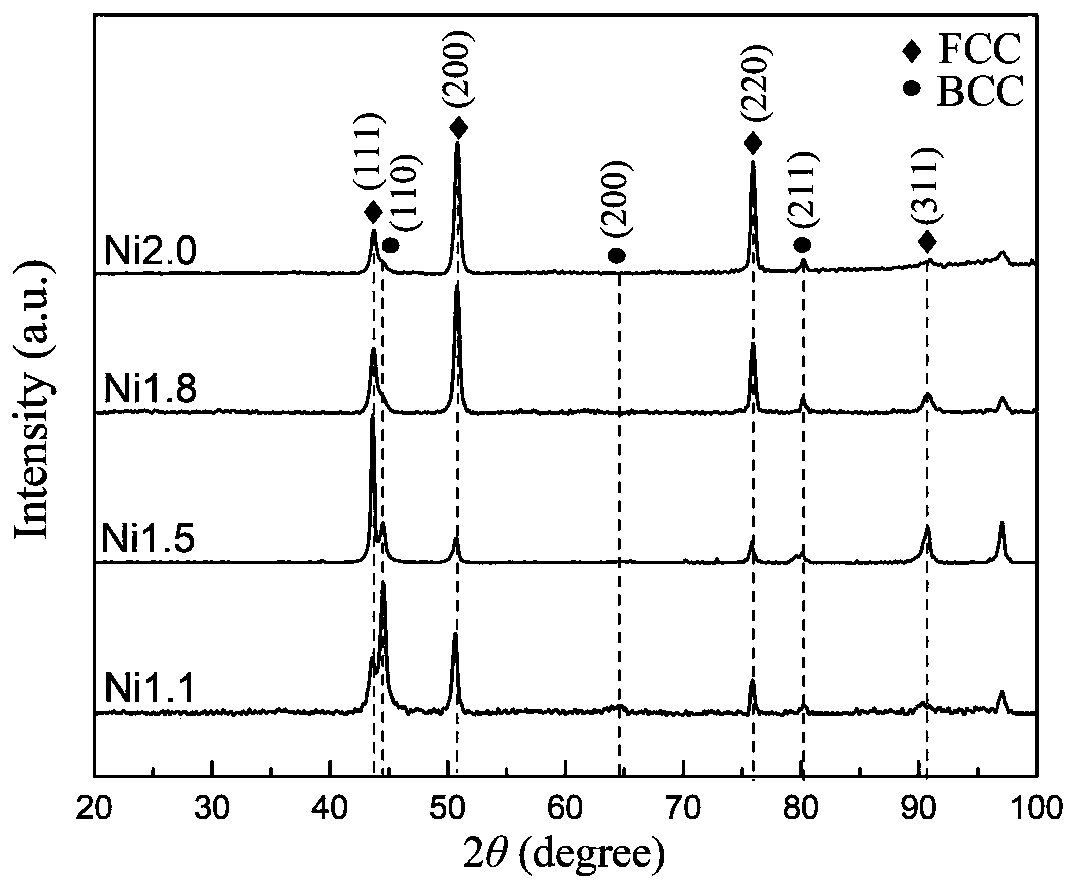

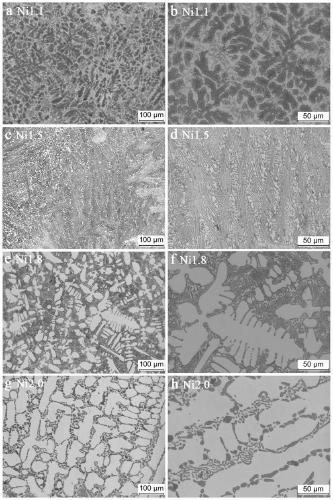

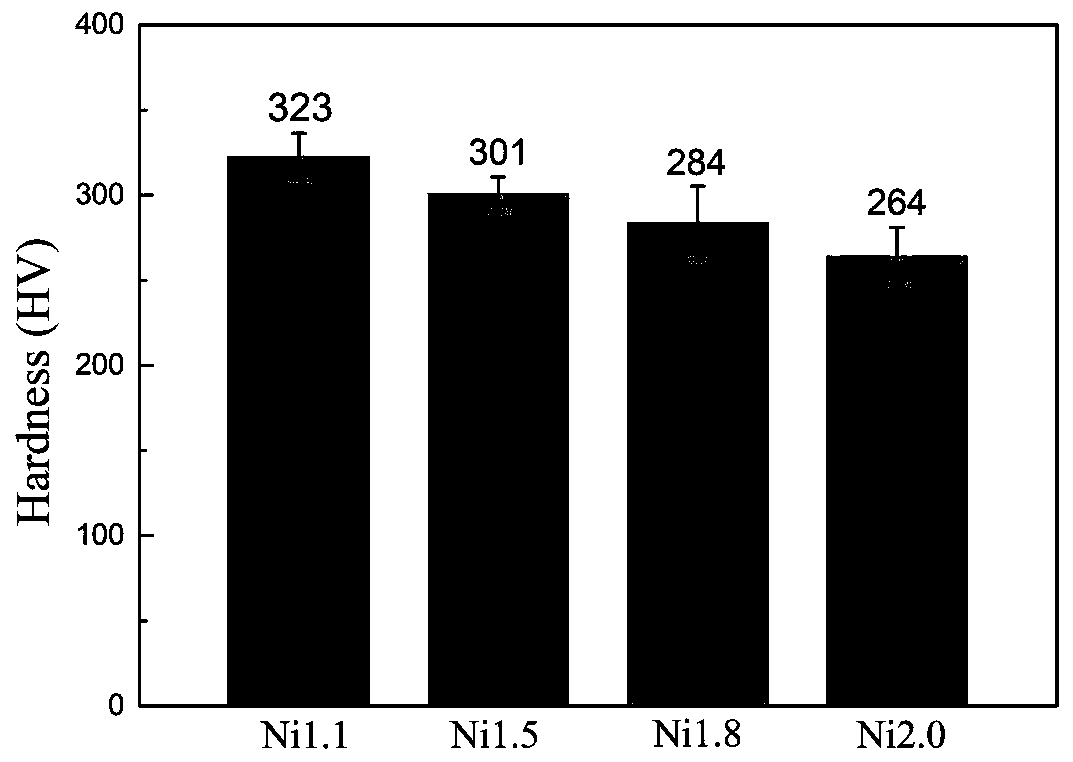

[0035] A dual-phase structure high-entropy alloy with good strong-plastic matching, the chemical formula is Al0.8CoCr0.6Fe0.7Ni1.1, wherein the ratio of each element is mole percentage, abbreviated as Ni1.1.

[0036] Use SiC sandpaper and a grinder to remove impurities and oxides on the surface of Al, Co, Cr, Fe and Ni elemental metal materials with a purity of ≥99.9wt%, then place them in a container and add alcohol solution, and use ultrasonic cleaning twice to remove Blow dry to obtain five kinds of raw materials;

[0037]According to Al:Co:Cr:Fe:Ni=0.8:1:0.6:0.7:1.1 precise molar ratio, Al, Co, Cr, Fe and Ni elemental metal raw materials are weighed in total 80g and mixed;

[0038] Put the mixed elemental metal raw materials in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of 2.4×10 ﹣3 Carry out alloying smelting under MPa, keep stirring during the smelting process, each smelting time is 10 minutes, obtain alloy liquid...

Embodiment 2

[0040] A eutectic high-entropy alloy with good strong-plastic matching, the chemical formula is Al0.8CoCr0.6Fe0.7Ni1.5, wherein the ratio of each element is mole percentage, abbreviated as Ni1.5.

[0041] Use SiC sandpaper and a grinder to remove impurities and oxides on the surface of Al, Co, Cr, Fe and Ni elemental metal materials with a purity of ≥99.9wt%, then place them in a container and add alcohol solution, and use ultrasonic cleaning twice, and then remove Blow dry to obtain five kinds of raw materials;

[0042] According to Al: Co: Cr: Fe: Ni = 0.8:1:0.6:0.7:1.5 accurate molar ratio, Al, Co, Cr, Fe and Ni elemental metal raw materials are weighed and mixed in total 80g;

[0043] Put the mixed elemental metal raw materials in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of 2.4×10 ﹣3 Carry out alloying smelting under MPa, keep stirring during the smelting process, each smelting time is 11min, obtain alloy liquid, ...

Embodiment 3

[0045] A hypoeutectic high-entropy alloy with good strong-plastic matching, the chemical formula is Al0.8CoCr0.6Fe0.7Ni1.8, wherein the ratio of each element is mole percentage, abbreviated as Ni1.8.

[0046] Use SiC sandpaper and a grinder to remove impurities and oxides on the surface of Al, Co, Cr, Fe and Ni elemental metal materials with a purity of ≥99.9wt%, then place them in a container and add alcohol solution, and use ultrasonic cleaning twice, and then remove Blow dry to obtain five kinds of raw materials;

[0047] According to Al:Co:Cr:Fe:Ni=0.8:1:0.6:0.7:1.8 accurate molar ratio weighs Al, Co, Cr, Fe and Ni elemental metal raw materials to add up to 80g and mixes;

[0048] Put the mixed elemental metal raw materials in a high-vacuum non-consumable arc melting furnace, under the protection of argon, at a vacuum degree of 2.3×10 ﹣3 Carry out alloying smelting under MPa, keep stirring during the smelting process, each smelting time is 10min, obtain alloy liquid, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com