A kind of detection method of microorganism in water environment

A water sample and indicator technology, applied in the field of microorganisms, can solve the problems of complex operation process, low sensitivity, complex instruments, etc., and achieve the effects of not easy to fade, large economic benefits, and excellent effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

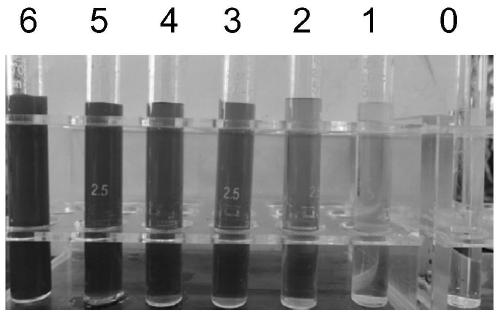

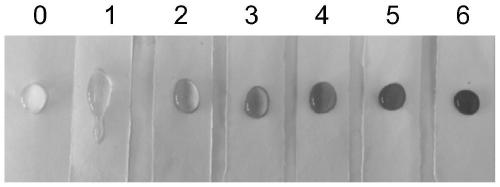

Examples

Embodiment 1

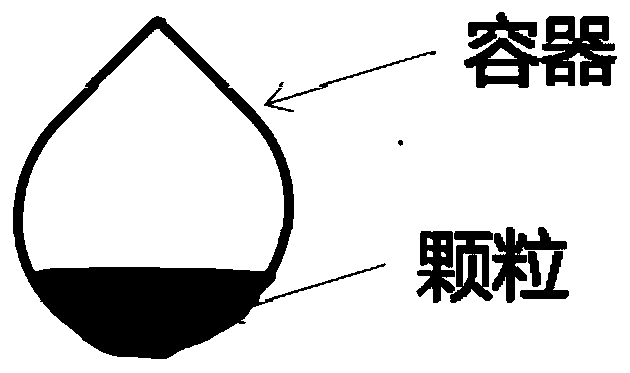

[0027] (1) Preparation of concentrated corn steep liquor particles:

[0028] Use a refiner to grind corn kernels into corn steep liquor. During the refining process, the mass ratio of corn kernels to water is 4:1. The ground corn syrup is first evaporated at 40°C to obtain corn steep liquor with a concentration of 40%. The material is then evaporated in a heating cycle at 80°C to obtain a basic dry product, which is dried at 90°C.

[0029] The final dried product is ground to a particle size of 100-500 nanometers, which is corn steep liquor concentrated particles.

[0030] (2) Dyed protein powder and corn steep liquor

[0031] Add 5 parts of protein powder, 3 parts of corn steep liquor granules and 30 parts of water into the reaction kettle, heat up to 60°C, stir evenly at 1000rpm, then slowly add 10mmol / L sodium persulfate dropwise at a rate of 1mL / min, add safflower 3 parts of dye, after the dropwise addition is completed, stir for 2 hours, let stand, and cool down to norm...

Embodiment 2

[0036] (1) Preparation of concentrated corn steep liquor particles:

[0037] Use a refiner to grind corn kernels into corn slurry. During the refining process, the mass ratio of corn kernels to water is 6:1. Evaporate the ground corn slurry, first at 50°C, to obtain a concentration of 50%. The corn slurry is then evaporated by heating cycle at 90°C to obtain a basic dry product, which is then dried at 100°C.

[0038] The final dried product is ground to obtain particles with a particle size of about 500 nanometers, which are corn steep liquor concentrated particles.

[0039] (2) Dyed protein powder and corn steep liquor

[0040] Add 8 parts of protein powder and 4 parts of corn steep liquor granules, 40 parts of water into the reaction kettle, heat up to 70°C, 2000rpm, stir evenly, then slowly add 10mmol / L sodium persulfate at a rate of 2mL / min, add safflower dye 3 parts, after the dropwise addition is completed, stir for 2 hours, let stand, and cool down to normal temperatu...

Embodiment 3

[0045] (1) Preparation of concentrated corn steep liquor particles:

[0046] Use a refiner to grind corn kernels into corn slurry. During the refining process, the mass ratio of corn kernels to water is 7:1. Evaporate the ground corn slurry, first at 60°C, to obtain a concentration of 50%. The corn slurry is then evaporated by heating cycle at 90°C to obtain a basic dry product, which is then dried at 100°C.

[0047] The final dried product is ground to obtain particles with a particle size of about 1000 nanometers, which are corn steep liquor concentrated particles.

[0048] (2) Dyed protein powder and corn steep liquor

[0049]Add 10 parts of protein powder, 5 parts of corn steep liquor granules, 50 parts of water into the reaction kettle, heat up to 80°C, 3000rpm, stir evenly, then slowly add 10mmol / L potassium persulfate at a rate of 3mL / min, add safflower dye 3 parts, after the dropwise addition is completed, stir for 2 hours, let stand, and cool down to normal temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com