Device and method for recovery treatment of solid-containing oil or oil-containing solid phase through solvent extraction

A technology for recycling and processing phase solvents, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve problems such as difficult treatment, pipeline wear, and processing difficulties, and achieve advanced, deductible, and technologically advanced and reliable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

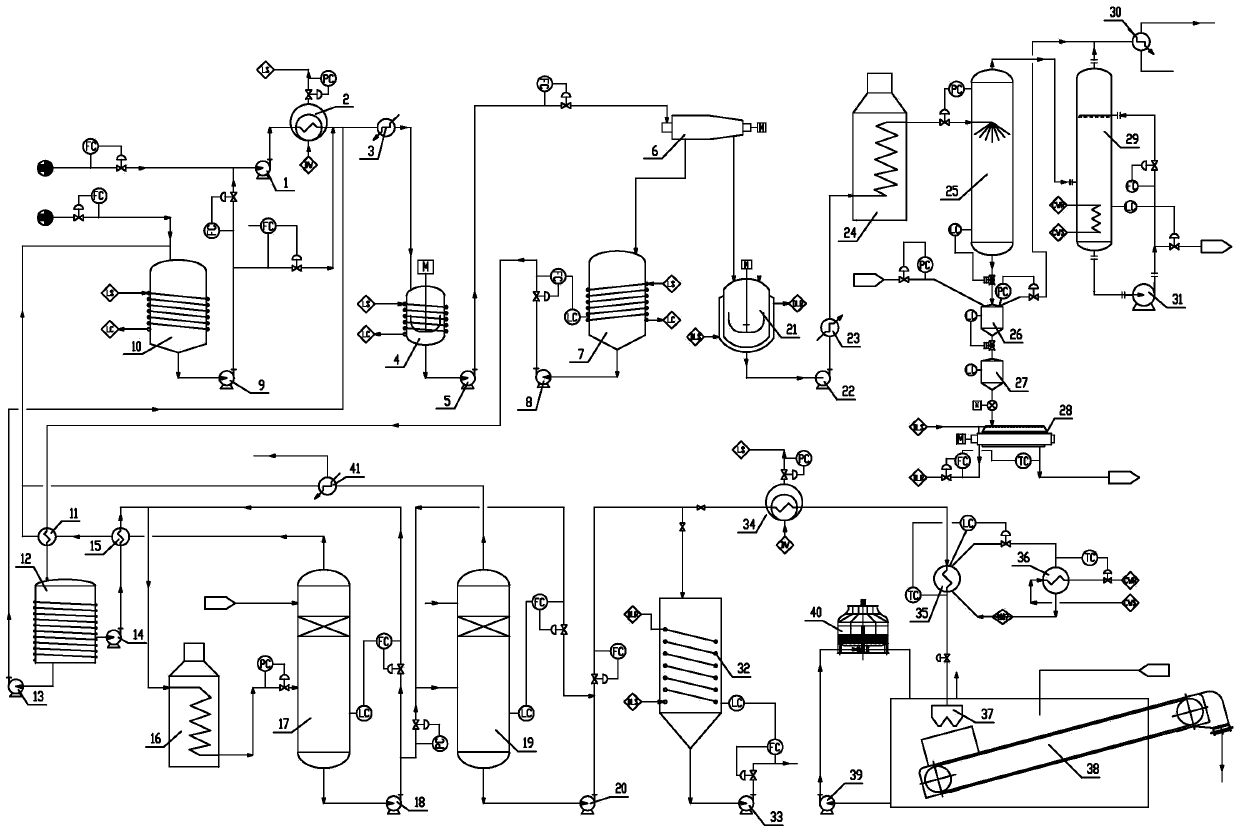

[0053] like figure 1 Shown: a solid oil-containing or oil-containing solid-phase solvent extraction and recovery processing device of this embodiment, the device includes an extraction centrifugal unit, a sedimentation unit, a flash evaporation unit, and a spray drying unit; the extraction centrifugal unit is used to The solid oil or oil-containing solid phase is extracted to obtain a centrifugal clear liquid and a centrifugal residue; the sedimentation unit is communicated with the extraction centrifugal unit to remove the solid particles in the obtained centrifugal clear liquid, and obtain a top liquid and a bottom liquid. The described flash unit is communicated with the settling unit to distill the obtained top liquid to obtain oil or bitumen and solvent, and the solvent is recycled after heat recovery; the described spray drying unit communicates with the extraction centrifuge unit for the purpose of The obtained centrifugal residue is subjected to solvent recovery to obt...

example 2

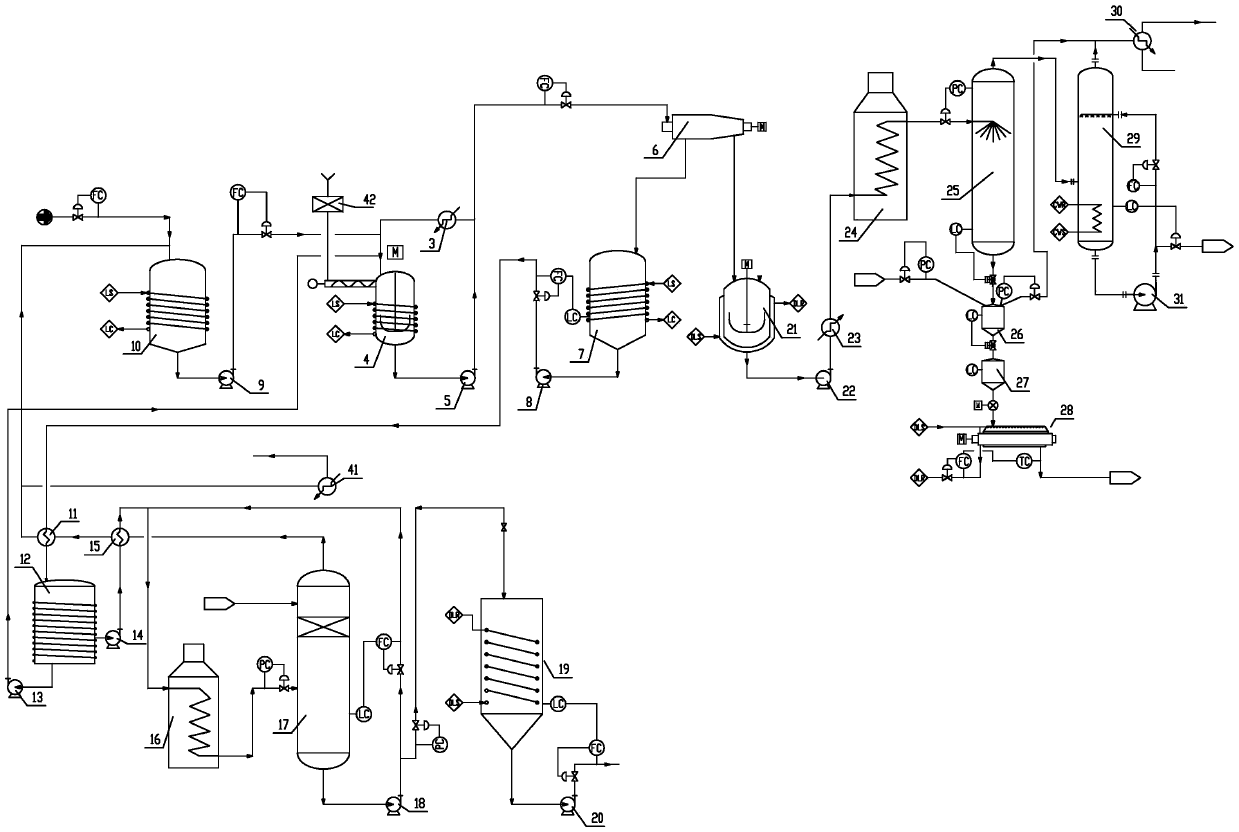

[0067] like figure 2 Shown: a solid oil-containing or oil-containing solid-phase solvent extraction and recovery processing device of this embodiment, the device includes an extraction centrifugal unit, a sedimentation unit, a flash evaporation unit, and a spray drying unit; the extraction centrifugal unit is used to The solid oil or oil-containing solid phase is extracted to obtain a centrifugal clear liquid and a centrifugal residue; the sedimentation unit is communicated with the extraction centrifugal unit to remove the solid particles in the obtained centrifugal clear liquid, and obtain a top liquid and a bottom liquid. The described flash unit is communicated with the settling unit to distill the obtained top liquid to obtain oil or bitumen and solvent, and the solvent is recycled after heat recovery; the described spray drying unit communicates with the extraction centrifuge unit for the purpose of The obtained centrifugal residue is subjected to solvent recovery to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com