PDMS micro-fluidic chip mould copying method

A microfluidic chip, replication method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc. The effect of promoting rapid development and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

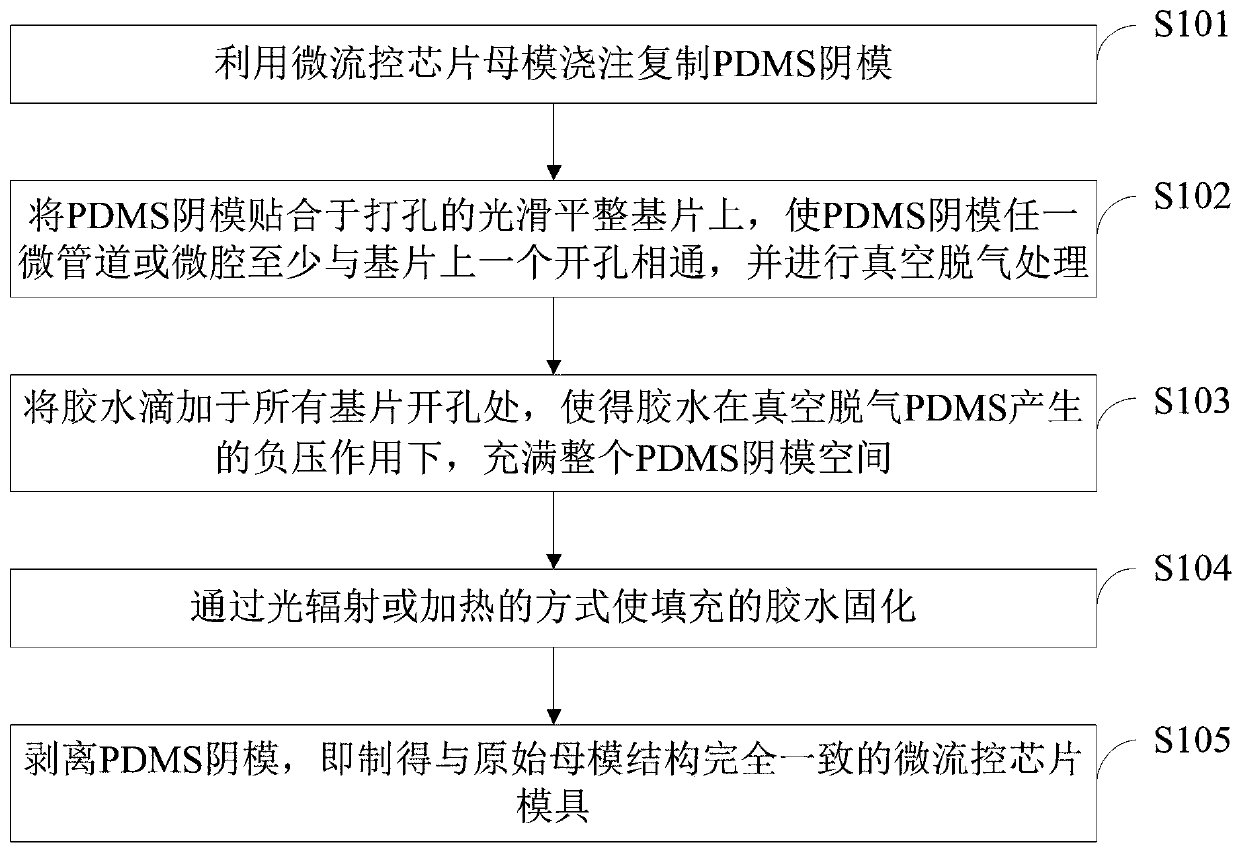

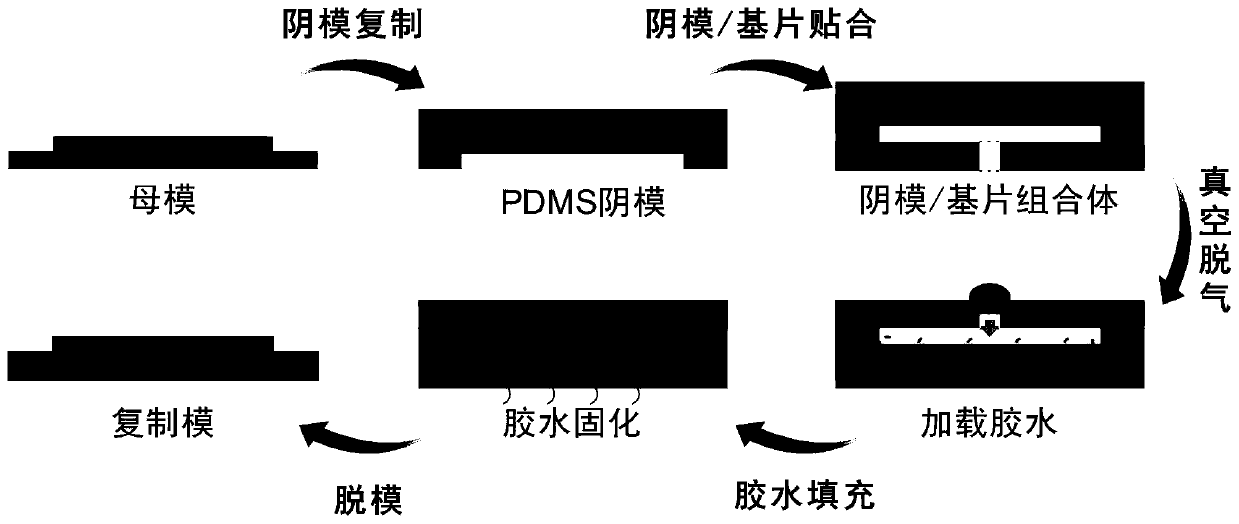

Method used

Image

Examples

Embodiment 1

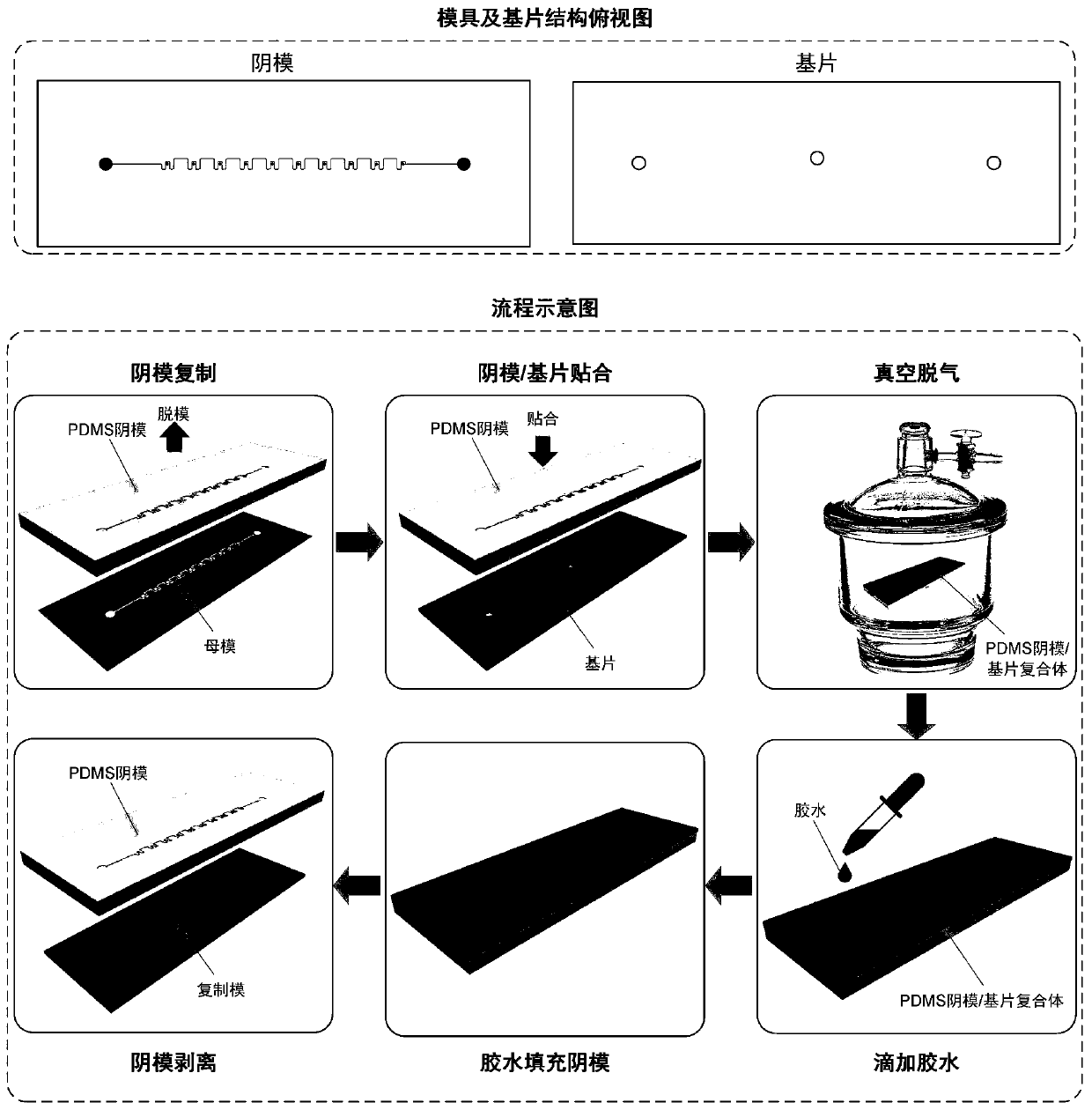

[0053] Such as image 3 As shown, based on the method of the present invention, a microfluidic chip mold integrating 1 micropipe and 10 microcavities is copied and manufactured for capturing droplets or microspheres. The specific steps are:

[0054] (1) Production of PDMS negative mold: First, mix a certain amount of PDMS precursor and cross-linking agent at a ratio of 10:1, and vacuum defoam, and then pour the PDMS prepolymer after vacuum defoaming on the microfluidic chip master mold , and heated on a 90°C hot plate for 1 hour to achieve PDMS curing; after the PDMS is cured, it is peeled off from the chip master mold to obtain a PDMS negative mold.

[0055] (2) Substrate preparation: In order to ensure that one micropipe and its 10 microcavities in series can be quickly and effectively filled with glue in the PDMS female mold, so as to realize the complete replication of the mold. First, use an ultrasonic puncher to make through holes with a diameter of 1.5 mm at the substr...

Embodiment 2

[0062] Such as Figure 4 As shown, based on the method of the present invention, a microfluidic chip mold integrating 40 micropipes and 20,000 microcavities is copied and manufactured for digital PCR research. The specific steps are:

[0063] (1) Production of PDMS negative mold: First, mix a certain amount of PDMS precursor and cross-linking agent at a ratio of 10:1, and vacuum defoam, and then pour the PDMS prepolymer after vacuum defoaming on the microfluidic chip master mold , and heated on a 90°C hot plate for 1 hour to achieve PDMS curing; after the PDMS is cured, it is peeled off from the chip master mold to obtain a PDMS negative mold.

[0064] (2) Substrate preparation: In order to ensure that the 40 microchannels of the PDMS female mold and the 20,000 microcavities connected in series can be quickly and effectively filled with glue, so as to realize the complete replication of the mold. First, use a glass knife to describe three independent microgrooves on a specifi...

Embodiment 3

[0071] Such as Figure 5 As shown, based on the method of the present invention, a microfluidic chip mold integrating 5000 independent microcavities and no connected micropipes is copied and manufactured for single-cell research. The specific steps are:

[0072] (1) Production of PDMS negative mold: First, mix a certain amount of PDMS precursor and cross-linking agent at a ratio of 10:1, and vacuum defoam, and then pour the PDMS prepolymer after vacuum defoaming on the microfluidic chip master mold , and heated on a 90°C hot plate for 1 hour to achieve PDMS curing; after the PDMS is cured, it is peeled off from the chip master mold to obtain a PDMS negative mold.

[0073] (2) Substrate preparation: In order to ensure that the 5,000 microcavities of the PDMS female mold can be quickly and effectively filled with glue, so as to realize the complete replication of the mold. First, according to the arrangement of the chip structure, use a laser marking machine to describe horizon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com