Preparation method and application of carbonyl hydrogenation catalyst

A technology of hydrogenation catalyst and carbonyl group, which is applied in the field of preparation of carbonyl hydrogenation catalyst, can solve the problems that the catalyst cannot achieve the expected catalytic effect, reduce the use efficiency of the catalyst, and the performance cannot be fully exerted, so as to improve the activity of the catalyst and enrich the acid-base sites and surface groups to improve the effect of hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

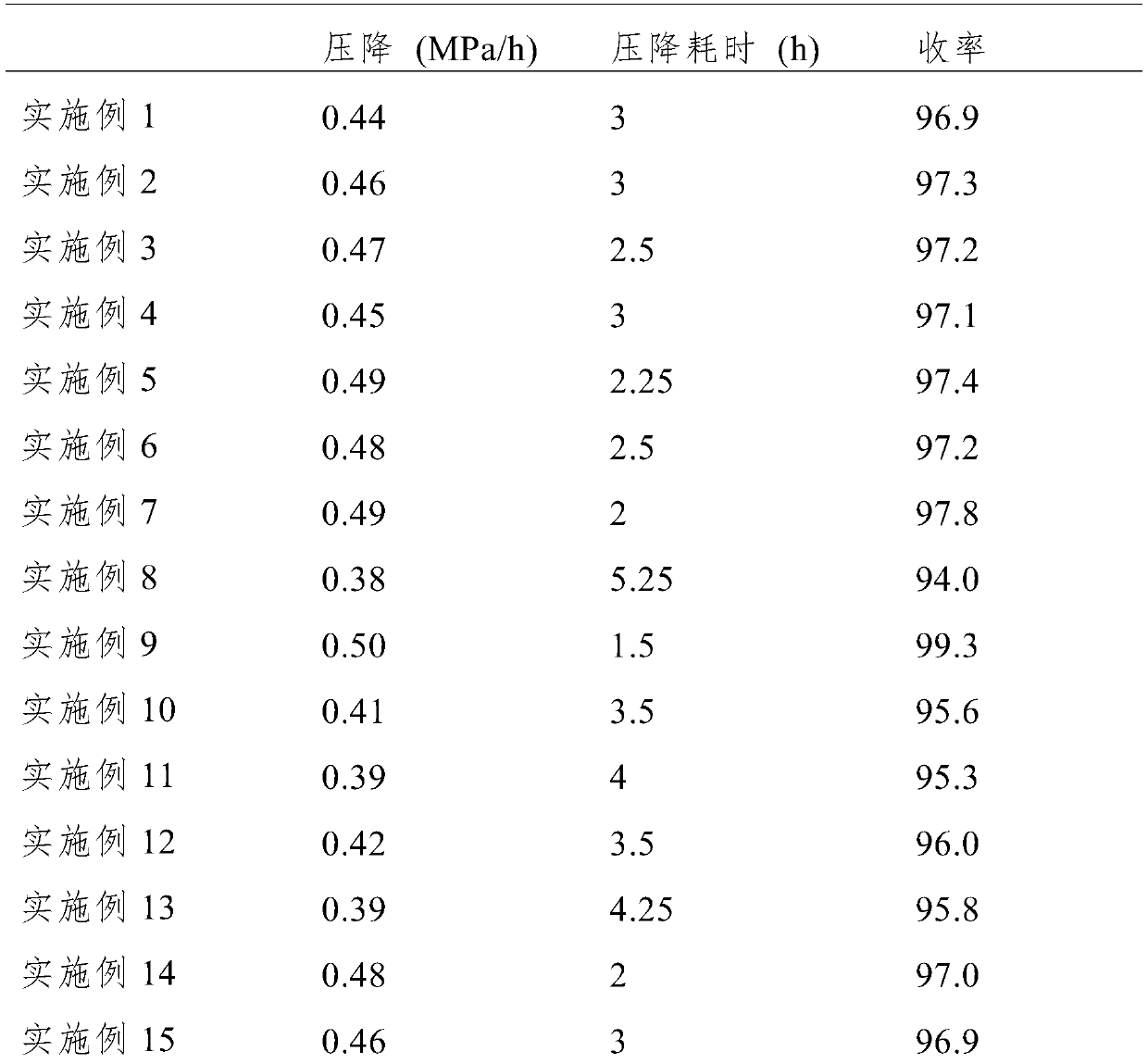

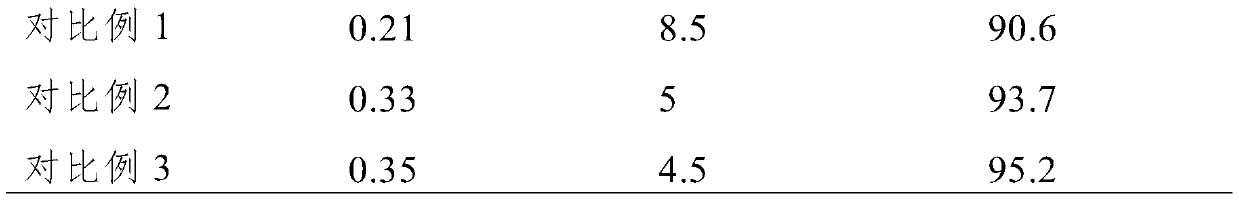

Examples

Embodiment 1

[0031] The preparation method of the carbonyl hydrogenation catalyst of the present embodiment may further comprise the steps:

[0032] Step 1, adding 100 g of activated carbon to 600 g of hydrochloric acid solution with a mass concentration of 2%, cooking at 80°C for 1 hour, filtering, washing the filtered activated carbon with pure water until the pH is 6, and obtaining acid-treated activated carbon;

[0033] Step 2, adding the acid-treated activated carbon obtained in step 1 into 500 g of a sodium hydroxide solution with a mass concentration of 15%, cooking at 70° C. for 2 h, filtering, and washing the filtered activated carbon with pure water until the pH is 8 , to obtain alkali-treated activated carbon;

[0034] Step 3, the alkali-treated gac obtained in step 2 is added to 1000 g of a mass concentration of 5% nitric acid solution, boiled for 2 h at 110° C., filtered, and the filtered gac is washed with pure water until the pH is 6 to obtain Oxygenated activated carbon;

...

Embodiment 2

[0040] The preparation method of the carbonyl hydrogenation catalyst of the present embodiment may further comprise the steps:

[0041] Step 1, adding 100 g of activated carbon to 1000 g of hydrochloric acid solution with a mass concentration of 5%, cooking at 110° C. for 0.25 h, filtering, washing the filtered activated carbon with pure water until the pH is 7, and obtaining acid-treated activated carbon;

[0042] Step 2, the acid-treated activated carbon obtained in step 1 is added to 800 g of a mass concentration of 25% sodium hydroxide solution, boiled for 0.5 h at 90° C., filtered, and the filtered activated carbon is washed with pure water until the pH is 7, obtain the activated carbon of alkali treatment;

[0043] Step 3, the alkali-treated activated carbon obtained in step 2 is added to 2000g of a mass concentration of 15% nitric acid solution, boiled for 5h at 80°C, filtered, and the filtered activated carbon is washed with pure water to a pH of 7 to obtain Oxygenate...

Embodiment 3

[0049] The preparation method of the carbonyl hydrogenation catalyst of the present embodiment may further comprise the steps:

[0050] Step 1, adding 100 g of activated carbon to 800 g of hydrochloric acid solution with a mass concentration of 3%, cooking at 100° C. for 0.5 h, filtering, washing the filtered activated carbon with pure water until the pH is 8, and obtaining acid-treated activated carbon;

[0051] Step 2. Add the acid-treated activated carbon obtained in step 1 into 600 g of 20% sodium hydroxide solution, cook for 1 h at 80° C., filter, and wash the filtered activated carbon with pure water until the pH is 6. , to obtain alkali-treated activated carbon;

[0052] Step 3, the alkali-treated gac obtained in step 2 is added to 1500 g of a mass concentration of 10% nitric acid solution, boiled for 3 h at 100° C., filtered, and the filtered gac is washed with pure water to a pH of 8 to obtain Oxygenated activated carbon;

[0053] Step 4, adding the oxidized activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com